What Are the Most Common Sources of Heat Used for Soldering or Brazing Copper Tube Joints?

Soldering and brazing both join copper tube joints using a molten filler metal, but they differ sharply in temperature, joint strength, and the heat sources required—differences that directly affect durability, leak resistance, and long-term performance.

In this guide, you’ll learn the core distinctions between soldering and brazing, how filler metals and flux influence joint quality, why choosing the right heat source matters, and what technicians should consider for proper heating, safety, and application. Whether you’re comparing torch types, evaluating furnace or induction heating, or selecting the right filler–flux combination, this guide shows you exactly how to make reliable, high-performance copper tube joints.

Soldering vs Brazing

Both soldering and brazing join copper tube joints by melting a filler metal that bonds the surfaces without melting the base copper. The two methods differ mainly in temperature, joint strength, and how heat is applied, which affects the durability and performance of the finished connection.

What Is Soldering?

Soldering is a low-temperature method that joins copper tubes using filler metal that melts below 840°F (450°C). A clean, oxide-free surface is essential because capillary action draws molten solder into the joint to form a tight seal.

Overall, soldering is a safe, quick option for moderate-pressure plumbing systems, especially near heat-sensitive components.

What Is Brazing?

Brazing is a high-temperature joining method that melts filler metal above 840°F (450°C), giving the joint greater strength and vibration resistance than soldering.

Its fillers—typically silver, copper, or nickel alloys—are what create strong metallurgical bonds with copper surfaces.

In practice, brazing is the choice for HVAC, refrigeration, and high-pressure systems because it withstands heat, pressure, and thermal cycling, and it enables joining dissimilar metals.

Filler Metals & Flux Essentials

Filler metals create the bond between copper tubes, and the right choice depends on joint temperature, pressure, and material compatibility.

- Soldering fillers often use tin-based alloys like 95/5 tin–antimony, tin–copper, or tin–silver.

- Brazing fillers use higher-temperature alloys such as BAg (silver–copper) or BCuP (copper–phosphorus), classified by AWS standards.

Flux removes oxides and helps the filler flow smoothly.、

- Rosin or water-soluble flux is used for soldering.

- Borax or fluoride flux is used for brazing because it can handle higher heat.

Choosing the correct filler–flux combination is essential.The wrong match can cause poor wetting, flux failure during heating, and weak or brittle joints.

Why Heat Source Matters

Because Heat sources provide steady, controlled temperature without damaging the copper. Air–fuel torches like propane or propylene are commonly used for soldering, while hotter oxy–fuel torches are used for brazing. Propane flames reach about 3600°F (1982°C), whereas oxy–acetylene can exceed 5700°F (3149°C) for high-temperature work.

Good heat control lets the filler flow properly by capillary action. Too little heat causes weak bonding, while too much heat can burn flux or oxidize the copper. Larger tubes especially need even heating to keep filler distribution uniform.

In practice, technicians match the heat source to the joint size and filler type. Choosing the right torch and fuel improves efficiency, reduces rework, and ensures durable copper tube joints.

Common Heat Sources

The three most common heat sources used are torch, furnace, and induction heating systems. Each method offers different levels of control, equipment cost, and heat distribution.

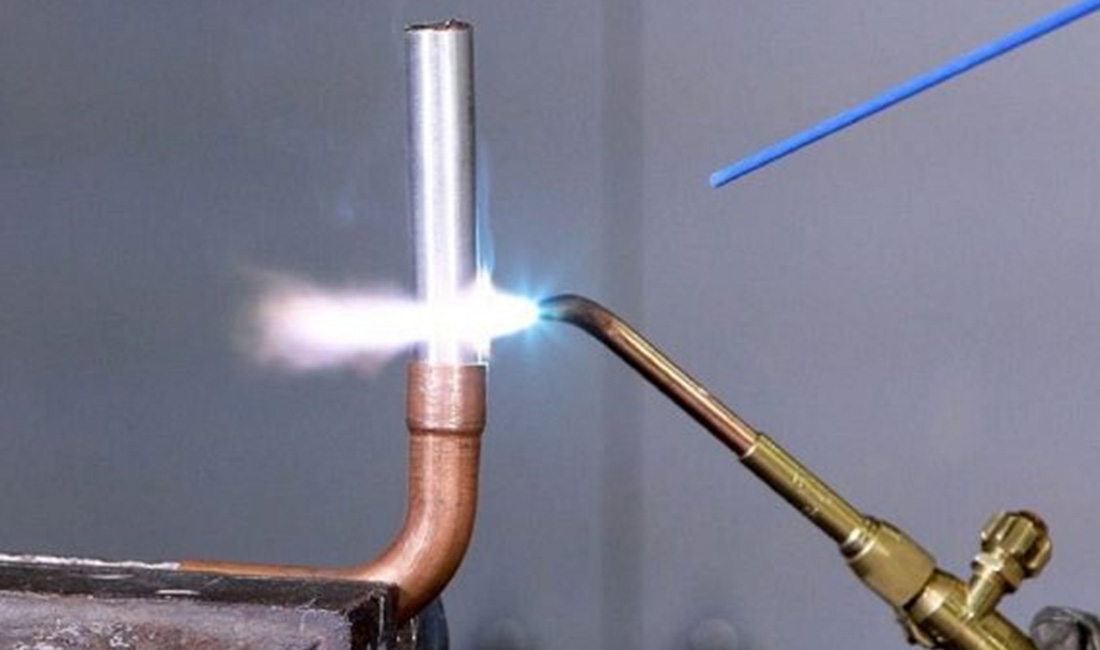

Torch heating remains the most widely used method for field and small-shop work. It uses a flame produced by a fuel gas system—typically air-acetylene, air-propane, or oxyacetylene.

- Air-acetylene torches provide a moderate flame temperature around 2,200–2,500 °C. This level suits soldering copper tubing common in plumbing.

- Air-propane systems burn propane with compressed air, producing a cooler flame but at lower cost and with easy cylinder handling.

- Oxyacetylene torches combine oxygen and acetylene to reach up to 3,100 °C, offering high localized heat for larger joints or thick copper. In practice, this allows faster heating and better control of joint penetration.

Furnace and induction heating are often used in shops or production lines. A furnace provides uniform heating for multiple assemblies at once. In contrast, induction uses electromagnetic fields to generate heat directly in the metal. For operators, this means faster, repeatable results with minimal oxidation risk.

The Comparison of Common Heat Sources

Different heat sources vary in temperature range, precision, and ease of use, which affects how well the joint forms and how much control the operator has.

Heat Source Comparison Table

| Heat Source | Typical Use | Temperature Range (°F) | Fuel or Power Type | Common Applications |

| Soldering Iron | Light soldering work | 400–800 | Electric resistance element | Fine tubing, small fittings |

| Air-Fuel Torch (Propane or Propylene) | General plumbing soldering | 3,600–3,700 | Combustion gas mixture | Copper pipes, small brazing tasks |

| Oxy-Fuel Torch (Oxyacetylene) | High-temperature brazing | Up to 6,300 | Oxygen + fuel gas | Larger joints, heavy copper tubing |

| Furnace | Industrial brazing operations | 1,000–2,000+ | Electric or gas heating | Mass or controlled-atmosphere brazing |

| Induction/Resistance Heating | Precision production joints | Variable up to 2,000+ | Electric current induction | Automated or repeatable operations |

Electric irons use resistance to create steady, localized heating, while torches rely on combusted gases like propane or propylene for open-flame control. Induction and furnace methods spread heat more evenly across larger parts.

How to Select the Right Heat Source

Choosing the right heat source depends on the heat requirements, the fitting size, and the type of fuel gas system in use. The goal is to apply enough heat to melt the filler metal without overheating or weakening the copper tube.

When selecting a fuel gas system, the technician should consider how quickly and evenly heat is delivered. For example, acetylene burns hotter and allows faster heat transfer, while propane provides a steadier, broader flame. In practice, this choice affects how easily solder or brazing filler melts and flows into the joint.

Different heating methods have specific advantages:

| Heat Source | Typical Use | Key Characteristic |

| Torch (Oxy-acetylene, Air-fuel) | Small assemblies, field repairs | Direct flame, portable |

| Furnace | Batch or continuous production | Uniform heating across assemblies |

| Induction | Precision brazing | Controlled, localized heating |

In most copper tube work, technicians prefer torch brazing because it gives precise control. Proper selection ensures strong, reliable joints without damaging the base metal.

How to Apply Heat Correctly

Here are the tips for applying heat correctly.

1.Apply Heat with Control

- Ensure the tube and fitting reach the same correct temperature for strong bonding.

- Avoid uneven heating, which prevents smooth filler flow.

- Use oxy-fuel or air-fuel torches for precise, concentrated heating.

2.Complete Joint Preparation Before Heating

- Clean surfaces thoroughly and remove oxidation.

- Apply a thin, even layer of flux.

- Flux prevents oxidation and acts as a temperature indicator—it turns clear and liquid when ready for solder/brazing.

3.Use Proper Torch Technique

- Keep the torch in constant motion to avoid overheating.

- Start heating the tube about 1 inch from the fitting, moving in short circular strokes.

- Once heated, shift to the fitting base, bringing both parts evenly up to temperature.

4.Understand Temperature Ranges & Filler Metals

- Soldering: ○Temp: Below 840°F (450°C) ○Filler: Tin-lead or lead-free tin alloys

- Brazing: ○Temp: Above 840°F (450°C) ○Filler: Silver- or phosphorus-based alloys

5.Apply Filler Metal Correctly

- Touch filler to the heated joint, never to the flame.

- Let the copper’s heat melt the filler, not the torch.

- Filler flows by capillary action, producing a dense, leak-free joint.

Safety Considerations

Here are some safety considerations to follow.

1.Protect Against High Heat

- Air-fuel torches, acetylene burners, and electric resistance tools can exceed 840°F (450°C).

- Wear heat-resistant gloves, eye protection, and long sleeves to prevent burns.

- Keep flammable or heat-sensitive materials away from the work area.

2.Ensure Proper Joint Preparation

- Poor prep can trap flux or filler, causing hot spots and uneven heating.

- Burned flux produces corrosive residues and irritating fumes.

- Use only the necessary amount of flux.

- Always clean copper surfaces before heating to improve solder flow and reduce contamination.

3.Manage Fume and Health Risks

- Lead-based solder creates hazardous fumes and dust if overheated.

- Modern practice uses lead-free alloys (tin-copper, tin-silver), but ventilation is still required.

- Maintain adequate airflow to remove vapors and protect air quality.

4.Handle Fuel Gases Safely

- Propane and acetylene are flammable and require leak checks before use.

- Store cylinders upright and secured to prevent tipping or gas buildup.

- When working near walls, insulation, or combustible materials, use a heat shield to prevent ignition.

Frequently Asked Questions

What are some common heat sources used for soldering copper tubing?

Most technicians use gas-fueled torches to heat copper joints. These torches burn fuels such as propane, acetylene, or natural gas, producing consistent flames that can quickly bring the metal to the required soldering temperature.

Electric resistance soldering tools and small electric soldering irons also serve as heat sources, especially for smaller or more delicate tubing. These tools generate heat through electrical resistance, which offers precise temperature control and reduces the risk of overheating flux or tubing.

By using equipment that allows steady, controllable heat, workers can maintain uniform temperature around the joint. In practice, this means smoother solder flow, fewer weak points, and a cleaner seal.

What are the typical gases used in the brazing process of copper tubes?

The most common fuel gases for brazing are acetylene, propane, and propylene. Each has a different flame temperature—acetylene reaches roughly 5,700°F (3,150°C) with oxygen, while propane and propylene burn slightly cooler. The choice of gas influences how quickly and evenly the joint heats.

Brazing typically uses an oxy-fuel system, which mixes fuel gas with oxygen to produce a controlled, high-temperature flame. Because oxygen supports complete combustion, this method allows precise heat placement along the tube and fitting.

For the user, this means faster heating and reliable filler-metal flow, which is essential for strong, leak-free copper tube joints in plumbing, refrigeration, and HVAC systems.

Want to Know More About Our Products?

View All Products Now