10 Top Fin and Tube Heat Exchanger Machinery Manufacturers: Leading Companies, Technology & Solutions

Fin and tube heat exchanger machinery plays a key role in controlling temperature across power, HVAC, refrigeration, and chemical systems. These machines use finned tubes to transfer heat efficiently between fluids, improving energy use and equipment performance. The top 10 fin and tube heat exchanger machinery manufacturers stand out for delivering reliable, high-efficiency equipment that meets industrial standards worldwide.

This article highlights leading companies shaping the global heat transfer industry through advanced engineering, consistent quality, and innovative manufacturing methods. It explains what fin tube heat exchangers are, compares major brands, and shows how each manufacturer supports specific industrial needs.

By the end, you’ll know how to identify trusted suppliers, evaluate machinery quality, and select the right heat exchanger systems for long-term performance and energy savings.

What Are Fin Tube Heat Exchangers?

A fin tube heat exchanger is a device that transfers heat between fluids using tubes fitted with extended metal surfaces called fins. These fins enlarge the surface area around the tubes, allowing faster and more efficient heat exchange between air and liquid. Their compact design, strong thermal performance, and ability to handle varied temperature conditions make them essential in HVAC, power generation, and industrial cooling systems.

Why are They Important?

Fin tube heat exchangers play a key role in controlling temperature in equipment and processes. By improving heat transfer efficiency, they prevent overheating, reduce energy loss, and keep machinery operating safely. Industries use them to recover waste heat, maintain precise temperature balance, and cut operational costs. Their durability and versatility keep them useful across sectors including oil refining, marine systems, and industrial refrigeration.

Market Demand Overview

Demand for finned tube heat exchangers continues to grow due to their reliability and adaptability in diverse environments. Global markets link this growth to trends such as stricter energy regulations and rising construction of data centers and renewable power plants. According to industry analyses, air-cooled heat exchangers form a strong segment of this market because they remove the need for external water sources. As sustainability standards tighten, companies increasingly select fin tube systems to meet both environmental and efficiency goals.

Market Leaders: 10 Top Fin and Tube Heat Exchanger Machinery Manufacturers

Fin and tube heat exchanger manufacturers continue to advance performance, efficiency, and reliability across a wide range of industries. Each company listed below plays a distinct role in shaping how industries manage heat transfer in sectors such as power generation, refrigeration, oil and gas, and industrial processing.

10 fin and tube heat exchanger market leaders include:

- Aidear

- Boyd Corporation

- Alfa Laval

- Wieland Thermal Solutions

- Sterling TT

- Thermex

- NEOTISS

- Schmöle

- Profins

- Tex-Fin

Aidear: Global Expertise in Heat Exchange Solutions

Aidear, also known as Changzhou Aidear Refrigeration Technology Co., Ltd., is a leading international supplier of integrated heat exchanger solutions. It focuses on resource integration and full-system design for refrigeration and thermal management needs.

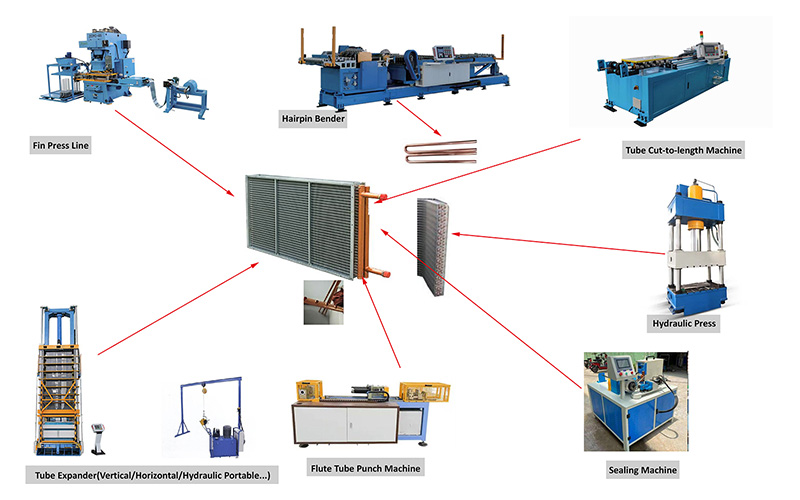

Core Machinery Types: Aidear manufactures finned tube exchangers, air coolers, condensers, and dry coolers. The company also offers automated assembly lines and raw materials for exchanger production.

Key Technology Highlights: Their fin tube systems maximize heat transfer efficiency through optimized fin geometry and durable materials. Advanced automation ensures product consistency and shorter delivery times.

Application Industries: Aidear serves HVAC, energy storage, cold chain logistics, and data centers. It also supports industrial refrigeration and transportation cooling solutions. The company’s focus on energy-saving and reliability has made it a preferred global supplier for large-scale projects.

Boyd Corporation: Custom Thermal Management

Boyd Corporation is a global thermal management company established in 1928, known for innovation in sustainable and custom-engineered cooling products. It evolved from its earlier brand, Aavid Thermalloy, into one of the most recognized heat exchanger manufacturers in North America and beyond.

Core Machinery Types: Boyd produces liquid-to-air and air-to-liquid fin tube heat exchangers built from copper, aluminum, or stainless steel. These are available in compact modular sizes that support tighter design spaces.

Key Technology Highlights: Their exchangers achieve high performance in small footprints, offering up to 75% space reduction compared to traditional designs. They emphasize manufacturability and system integration for different heat dissipation requirements.

Application Industries: Boyd provides cooling solutions for electronics, aerospace, automotive, and industrial processing. Its customization capability makes it ideal for applications that demand thermal stability in limited spaces.

Alfa Laval: Pioneering Heat Transfer Innovation

Alfa Laval, founded in 1883, is a Swedish multinational firm specializing in heat exchanger solutions, separation, and fluid handling. It is one of the largest global providers of heat transfer systems serving both process and utility applications.

Core Machinery Types: The company produces finned tube exchangers, plate heat exchangers, and shell-and-tube systems. Its products are scalable, from compact units to industrial plant systems.

Key Technology Highlights: Alfa Laval focuses on energy-efficient design, material flexibility, and easy maintenance. Many models feature corrosion-resistant alloys and patented surface enhancements that improve thermal flow.

Application Industries: It supplies solutions to oil and gas, power, food processing, marine, and renewable energy sectors. Consistent service support through its global network ensures low operational downtime and high lifecycle value.

Wieland Thermal Solutions: A Legacy of Metal Mastery

Wieland Thermal Solutions, part of the Wieland Group, has more than two centuries of metal manufacturing history. The company is known for its precision metal tubing and custom-engineered fin tube heat exchangers.

Core Machinery Types: Wieland manufactures high-fin, low-fin, and internally enhanced tubes under its GEWA and TURBO lines. These are available in copper, aluminum, and stainless steel variants.

Key Technology Highlights: Proprietary fin-forming techniques improve heat transfer efficiency and fluid drainage. Wieland also tailors surface treatments for use in refrigeration and high-temperature industrial environments.

Application Industries: The company’s exchangers are widely used in HVAC, refrigeration, energy, and chemical processing. Their durability and thermal optimization allow operation in both compact and heavy-duty installations.

Sterling TT: A Century of Cool

Sterling TT, based in the United Kingdom, has over 100 years of engineering experience producing heat exchanger solutions for global industries. It combines long-standing craftsmanship with advanced thermal technology.

Core Machinery Types: The company offers extended surface finned tube exchangers such as its Elfin and HEI lines. These come in a selection of copper alloys and titanium structures.

Key Technology Highlights: Sterling TT’s strength lies in system customization and design flexibility. Its exchangers are available for retrofit projects and new installations, featuring adaptable fin configurations and materials.

Application Industries: It supports power generation, marine engineering, and HVAC projects. Sterling TT’s multi-material approach allows robust performance in corrosive or high-pressure conditions.

Thermex: Heat Transfer Expertise

Thermex is a UK-based manufacturer specializing in heat transfer equipment for over four decades. It delivers off-the-shelf and custom fin and tube exchangers used across industrial and marine operations.

Core Machinery Types: Thermex produces tube-and-fin exchangers, oil coolers, and water-cooled systems. These are designed to handle harsh operating conditions.

Key Technology Highlights: Its systems enhance heat dissipation efficiency by up to several hundred percent through advanced surface area expansion. Thermex also maintains materials expertise, using copper-nickel, stainless steel, and titanium for environment-specific durability.

Application Industries: Thermex products are deployed in marine engines, energy, and heavy industry. Compact configurations make them suitable for both standard systems and retrofit operations.

NEOTISS: Process Engineering Excellence

NEOTISS is a multinational producer of high-performance tubing solutions, originally known as High Performance Tube, Inc. The company has expertise in finned and welded tubes designed for extreme environments.

Core Machinery Types: NEOTISS designs titanium and stainless-steel high-finned tubes that meet the standards of refineries, power plants, and petrochemical facilities.

Key Technology Highlights: Its proprietary forming and welding processes improve corrosion resistance and mechanical strength. These tubes maintain high transfer efficiency under high pressure or temperature conditions.

Application Industries: NEOTISS serves oil and gas, power generation, and desalination applications. Its materials and engineering design ensure reliability in corrosive conditions and long lifecycle performance.

Schmöle: Engineering Custom Solutions

Schmöle GmbH, based in Germany, has a history of over 160 years in producing precision finned tubes and custom heat exchanger systems. It is known for combining traditional engineering expertise with modern thermal technology.

Core Machinery Types: Schmöle manufactures low-, medium-, and high-fin tubes, including laser-welded and mechanically bonded designs. The company also provides surface-finished tubes for specialized installations.

Key Technology Highlights: Its laser welding techniques provide stronger metal bonds and improved heat transfer compared to conventional methods. This approach also enhances corrosion protection.

Application Industries: Schmöle serves HVAC, power, and process industries requiring dependable and tailored components. Its in-house metal fabrication ensures high precision and design consistency.

Profins: Integrated Process Solutions

Profins, founded in 1978 in the United Kingdom, focuses on producing finned tube exchangers and metal tubing for industrial use. It is recognized for reliable product quality and fast delivery cycles.

Core Machinery Types: The company manufactures spiral and longitudinal finned tubes, plain tubes, and headers. It also handles bending and forming operations internally.

Key Technology Highlights: Profins emphasizes efficient production with in-house bending technology and automated finning machinery. This allows precise tube geometry and faster turnaround on custom orders.

Application Industries: Its exchangers are used in petrochemical plants, power generation, and air-cooled systems. Profins’ flexibility in production enables strong performance in project-driven environments.

Tex-Fin: Texas-Born Heat Solutions

Tex-Fin, established in Houston in 1964, is a full-service heat exchanger manufacturer with strong roots in the North American market. It offers both manufacturing and maintenance support within the energy and industrial sectors.

Core Machinery Types: Tex-Fin designs and fabricates high-frequency welded finned tubes, air-cooled exchangers, and ASME-certified pressure vessels.

Key Technology Highlights: Their exchangers feature high thermal conductivity materials and precision welding for consistent performance. Tex-Fin’s 24/7 service model provides continuous operational support for critical systems.

Application Industries: The company caters to oil and gas, power, and petrochemical industries across the United States. Its focus on reliability and certification compliance ensures dependable, field-ready products that meet demanding thermal performance standards.

Comparison of the Top Manufacturers

Leading fin and tube heat exchanger manufacturers differ in how they approach heat transfer technology, what industries they serve best, and where they maintain production and service advantages. Small design details, material choices, and production methods shape their standing in the market.

Technology Comparison Matrix

Manufacturers like Alfa Laval and GEA Group rely on compact, high-efficiency fin tube designs that use advanced surface enhancement to increase heat exchange performance. Boyd and Thermex specialize in lightweight assemblies that fit smaller enclosures, while Sterling TT and Wieland Thermal Solutions focus on customizable fin geometries and material flexibility.

API Heat Transfer and SPX Flow have invested heavily in automated manufacturing to improve consistency and reduce waste. GEA’s laser-welded fins and Wieland’s GEWA tubes show precise fabrication that boosts durability under high pressure. In contrast, Profins and Tex-Fin emphasize modular construction for easy maintenance and replacement.

Industry Fit

Each company aligns with distinct industrial needs. Alfa Laval, GEA Group, and API Heat Transfer serve heavy sectors like oil, gas, and power where equipment reliability and corrosion resistance are critical. Boyd and Sterling TT fit data centers, HVAC, and electronics cooling where space and flexibility matter.

Wieland and NEOTISS operate in specialized tubing for energy and chemical processing plants. SPX Flow and APV provide process heat transfer systems for food, pharmaceutical, and beverage industries that demand hygiene-focused designs. For marine and transport applications, Thermex stands out due to corrosion-resistant materials that handle saltwater conditions well.

Regional Strengths

GEA Group and Alfa Laval maintain strong European roots with global branches across Asia and North America. Their networks allow local support with consistent design standards. SPX Flow and API Heat Transfer, both U.S.-based, have strong positions in the Americas with growing manufacturing partnerships in Asia.

Sterling TT, Profins, and Thermex anchor their production in the United Kingdom, giving them regional agility for European orders. NEOTISS, with operations in France and Asia, benefits from quick distribution for energy and refinery sectors. Tex-Fin, located in Texas, leverages proximity to the Gulf’s oil and gas markets for fast deliveries.

How to Choose the Right Machinery Supplier?

Selecting the right machinery supplier affects equipment reliability, energy efficiency, and long-term production costs. Key factors include output capacity, material compatibility, fin geometry options, and the balance between purchase price and service life.

Volume Requirements

Production volume defines both the size and configuration of a fin and tube forming line. A supplier should offer machines that match the company’s output goals while maintaining stable performance during continuous operation. For low-volume or custom projects, a modular system with flexible tooling works best. Evaluating throughput rates in meters of tubing per minute or fins produced per hour helps identify equipment suited to the workload.

When reviewing proposals, comparing cycle time, changeover speed, and available spares provides a clear picture of both productivity and operational risk. Selecting a machine that slightly exceeds current needs can prevent early obsolescence and support future expansion.

Tube Material Compatibility

Tube material compatibility determines how well a machine handles copper, aluminum, stainless steel, or titanium tubing. Each material has different hardness and forming characteristics, so the line must include appropriate rolling pressure control, cutting precision, and lubrication systems.

Suppliers that design forming heads and welding stations for multiple alloys offer more flexibility. Testing a sample batch with the intended tube stock before purchase helps confirm that wall thickness tolerances stay within required limits. A good supplier will assist with these validation steps and provide documented standards such as ASME or ISO 9001 compliance.

Fins Type & Production Speed

Fin type and speed define the machine’s range. A strong supplier provides dies or rollers that achieve precise fin pitch and height while maintaining uniform bonding to the tube surface. Equipment with CNC-based fin mills and automatic alignment systems reduces setup errors and improves production efficiency.

Machine speed directly influences energy savings and operating cost. Faster doesn’t always mean better if quality suffers. Balanced output matched to the expected duty cycle ensures stable performance, long tool life, and steady product quality over time.

Budget vs Lifetime Cost

Budget versus lifetime cost compares the immediate purchase expense with ongoing maintenance, energy use, and downtime. Machines with energy-efficient drives and automated controls may cost more initially but deliver greater energy savings and productivity over years of operation.

Suppliers should disclose expected maintenance intervals, spare part availability, and technical support response times. A supplier that balances competitive pricing with durability and service reliability typically yields the best return across the equipment’s full life cycle.

FAQs

What are the most critical parameters that impact a heat exchanger’s performance?

A heat exchanger’s performance depends on factors such as fin density, tube material, airflow rate, and temperature difference between fluids. The fin density determines how much surface area is available for heat transfer, while the material affects thermal conductivity and corrosion resistance.

Fluid flow rates on both sides also play a vital role. Too high, and pressure drops increase; too low, and heat transfer declines. Design engineers balance these with operating conditions to ensure thermal efficiency without overloading pumps or fans.

What innovative technologies are being incorporated by manufacturers in fin and tube heat exchangers?

Manufacturers have begun using laser-welded fins, compact geometries, and reduced-weight alloys to improve performance and durability. These designs allow for tighter control of heat movement and better resistance to vibration and corrosion.

Advances such as additive manufacturing and computational fluid dynamics (CFD) modeling now help optimize fin shapes and spacing before production. Some companies integrate smart monitoring sensors to track system health and predict maintenance needs, improving uptime and longevity.

Which manufacturers offer custom solutions?

Several major producers provide custom-built exchangers tailored to unique system requirements. Boyd Corporation designs compact units that can be configured for specific power or space limits. Sterling TT and Aidear both specialize in one-off or modified systems, allowing changes in material, size, and fin design to meet project goals.

Tex-Fin and Profins also deliver custom fabrication services with fast turnaround times. They often modify tube configurations, mounting styles, or coatings to match environmental or performance requirements.

Want to Know More About Our Products?

View All Products Now