Tube Forming Machinery, Tube Processing Machinery and Tube Manufacturing Machinery: Key Differences and Applications

Tube forming machinery, tube processing machinery, and tube manufacturing machinery are related but not identical. Each term refers to a distinct stage of working with metal tubes from shaping and bending raw tubing to finishing, joining, and producing final assemblies. In manufacturing, precision and clarity matter because each machine type serves a specific purpose that affects production speed, material performance, and cost efficiency.

Industrial engineers, metal fabricators, and production managers use these systems daily to create parts for automobiles, HVAC systems, aerospace components, and structural frameworks. Companies with deep experience in mechanical forming, such as those manufacturing CNC tube benders and pilger mills, understand that choosing the right machine type determines quality and dimensional accuracy.

This article explains what defines tube forming, processing, and manufacturing machinery, how each contributes to the production chain, and where they overlap. It also covers key industrial methods, like bending, cutting, expansion, and pilgering and offers practical guidance for comparing equipment types across different applications.

What is Tube Forming Machinery?

Tube forming machinery refers to equipment that bends, expands, reduces, or reshapes metal tubes into precise configurations. It uses mechanical or hydraulic force to plastically deform materials like stainless steel, aluminum, brass, and titanium. Because these metals are ductile, they can be reshaped without cracking or losing structural strength.

Most modern tube forming machines rely on cold working processes. Cold forming changes the tube’s geometry at room temperature, producing smooth finishes and accurate dimensions. In practice, this reduces the need for secondary machining and helps maintain uniform material properties throughout the tube.

CNC-controlled tube formers increase process accuracy because they automate die positioning and motion control. In practice, this allows tighter tolerances and repeatable production in sectors such as automotive, aerospace, and construction, where consistent tube geometry directly affects system safety and performance.

Common forming methods include bending, flaring, beading, expanding, shrinking, and swaging. Each method serves a specific purpose:

- Bending changes direction or angle.

- Flaring widens the tube end for sealed joints.

- Beading adds raised rings for hose retention.

- Expansion or reduction adjusts diameters for fittings or assembly alignment.

What is Tube Processing Machinery?

Tube processing machinery refers to a range of equipment used to cut, bend, shape, and finish metal tubes into precise dimensions. These machines transform raw tubing—often made from steel, aluminum, or copper alloys—into usable components for industries such as automotive, aerospace, and construction.

Unlike tube forming machines, which mainly change a tube’s shape, tube processing machinery covers multiple stages like cutting, deburring, chamfering, polishing, and end forming. Each stage involves tools and control systems designed to deliver consistent accuracy, often within ±0.1 mm. In practice, this precision allows manufacturers to meet tolerance standards for hydraulic lines or structural assemblies without manual correction.

Modern tube processing machines often integrate CNC controls and sensor feedback systems. Because the computer continuously monitors tube position and forming pressure, it can adjust operations automatically. For the user, this means repeatable production with less material waste and shorter setup time.

When combined in a single production line, these machines handle nearly every modification required before assembly, improving alignment between design and finished parts without extra rework steps.

Common machine types include:

- Sawing or Laser Cutting

- Bending

- End Forming

- Chamfering & Deburring

What is Tube Manufacturing Machinery?

Tube manufacturing machinery is an equipment that transforms raw metal into finished tubes through controlled forming, shaping, and welding steps. These systems handle materials such as carbon steel, stainless steel, copper, and aluminum, each chosen for its ductility and strength. Because these machines guide metal through multiple shaping stages, they determine the final dimensions, wall thickness, and surface finish of the tube.

The process often begins with flat metal strips or coils that are uncoiled, shaped into cylindrical forms, and welded longitudinally or seamlessly drawn through dies. Seamless tube mills create tubes without weld seams, while welded tube mills join edges using electric resistance or high-frequency welding units. In practice, this choice affects mechanical strength and cost—seamless tubes resist internal pressure better, while welded lines suit high-volume production.

Automated control systems monitor speed, alignment, and weld integrity to maintain consistency. In other words, when sensors and feedback loops manage these variables, operators can produce precise tubing that fits the demanding tolerances of automotive, construction, and energy applications.

A typical tube manufacturing line may include:

- Forming Section

- Welding Station

- Sizing or Reducing Mill

- Cutting and Straightening

- Testing Section

Comparing the Machinery Types: Are They the Same?

Tube forming, processing, and manufacturing machinery all handle metal tubes, yet their functions and uses differ. Each category focuses on specific steps—shaping, handling, or producing tubes from raw stock—creating both overlap and specialization across industrial environments.

Core Functions and Differences

Tube forming machinery changes the shape or geometry of existing tubes. Examples include tube benders, end formers, and flaring machines. These machines rely on mechanical deformation—such as rotary draw bending or hydraulic pressing—to alter the tube’s path or end profile without cutting or welding. Because forming focuses on geometry, these systems are key in producing elbows, exhaust pipes, and heat exchanger coils.

Tube processing machinery handles supporting or secondary operations. This category may include cutting, deburring, or polishing machines. These machines refine dimensional accuracy, surface condition, or length. For instance, a CNC tube saw ensures consistent cut angles and minimal burrs, which matters for sealed joints in fluid systems.

Tube manufacturing machinery works earlier in the production chain. Equipment such as tube mills and pilgering machines converts flat metal strips or billets into hollow tubes. The process can use high-frequency electric resistance welding (ERW) or seamless extrusion. In practice, this machinery defines the tube’s diameter, wall thickness, and metallurgical integrity long before forming begins.

Overlapping Processes and Equipment

The boundaries between these machinery types sometimes blur. A tube mill line may incorporate forming rolls that shape the metal strip into a tube before welding—a forming process that happens as part of manufacturing. In the same way, a processing station might include simple end-forming attachments for post-production adjustments.

Overlap often occurs in automation. A production cell may integrate bending, cutting, and inspection into one CNC-controlled line. This setup reduces handling time because the tube stays within the same work zone from start to finish. For operators, this means higher consistency and fewer alignment errors when changing from one operation to another.

Below is a table of the main purpose of forming, processing and manufacturing:

| Category | Main Purpose | Example Machines |

| Forming | Shape existing tubes | CNC benders, flaring machines |

| Processing | Prepare or finish tubes | Cutters, washers, deburring units |

| Manufacturing | Create tubes from raw metal | Tube mills, pilgering machines |

Industry Usage Variations

Different industries define these categories based on workflow. Automotive plants generally use pre-manufactured steel or aluminum tubes, focusing on forming and processing tasks such as precision bending for exhaust or brake systems. HVAC and refrigeration manufacturing rely on hairpin and return benders for repetitive 180° copper bends, followed by end forming for leak-proof joints.

In contrast, energy and aerospace sectors emphasize tube manufacturing for seamless, high-strength tubing. Cold pilgering and autofrettage equipment strengthen the metal at a microscopic level, improving fatigue resistance under pressure. For these users, control of wall thickness and surface finish is critical because it affects safety and system efficiency.

In smaller fabrication shops, combined forming-processing machines are common. This approach saves floor space and simplifies operator training. It illustrates how industry scale and product requirements—not just machine type—determine how “tube forming,” “processing,” and “manufacturing” categories apply in daily production.

Key Industrial Processes in Tube Production

Industrial tube production relies on several core processes that shape, join, and finish metal tubes to meet precise dimensional and performance requirements. Each stage, from bending to straightening, uses specialized machinery that determines the tube’s strength, uniformity, and reliability in its final application.

Tube Bending Processes

Tube bending reshapes straight tubing into defined angles or curves without collapsing the walls. Manufacturers use rotary draw, compression, roll, and mandrel bending depending on the required radius and material type. For example, a mandrel bending machine uses an internal steel rod to support the tube during bending, which prevents wrinkling and keeps the inside diameter uniform.

Materials like stainless steel, copper, and aluminum respond differently to bending forces. The chosen process depends on tensile strength and wall thickness. In practice, a tube bender applies controlled pressure through rotating dies that guide the metal around a fixed form. The accuracy of these tools affects assembly fit and joint alignment.

For the operator, this means consistent shapes that reduce weld gaps and material waste. Proper bending also improves flow performance in systems where internal smoothness matters, such as hydraulic or fuel lines.

Welded vs Seamless Tube Production

Tube production follows two main paths: welded and seamless. Welded tubes start from flat strips of metal rolled into a cylindrical shape and joined by a longitudinal or spiral weld using MIG, TIG, or plasma methods. This approach allows wide size variety and lower production cost because sheet material is easier to handle than billets.

In contrast, seamless tubes begin as solid cylindrical billets pierced and elongated by processes such as the Mannesmann or Mandrel Mill. The absence of a weld line gives them uniform strength around the circumference. As a result, they can withstand higher internal pressures and temperatures.

For users in oil, gas, or structural applications, this translates into safer performance under mechanical stress. Welded tubes remain preferred when dimensional precision and cost efficiency matter more than extreme pressure resistance.

Tube Straightening and End Forming

After production, tubes often require finishing to meet dimensional standards. A tube straightener uses a sequence of adjustable rollers arranged in alternating planes to remove curvature from the manufacturing process. Each roller slightly bends the tube in the opposite direction of its curve, gradually restoring linearity. Consistent roller alignment ensures straightness within millimeter tolerances.

End forming operations—such as flaring, swaging, expanding, or beading—shape tube ends for better connection and sealing. These processes use hydraulic or mechanical presses fitted with dies that define the final geometry.

In practical terms, this means the tube can connect directly to fittings or other components without leaks or alignment issues. Accurate straightening and end forming also allow automated assembly systems to feed and join tubes without manual correction, improving production speed and repeatability.

Types of Machines Used in Tube Manufacturing

Tube manufacturing relies on equipment that bends, shapes, and finishes metal tubes with precision. Each process changes the tube’s geometry or wall characteristics to meet structural, pressure, or assembly needs. The following machines represent the main types used during metal tube fabrication in modern plants.

Tube Bending Machines

Tube bending machines, or tube benders, reshape straight tubing into curved or angled forms without weakening the material. They apply force through dies that control both bend radius and direction. Rotary draw benders use a rotating die and clamping system to pull the tube into shape while minimizing wall thinning.

CNC tube benders employ servo-driven axes and digital programming to repeat complex angles within tolerances of ±0.1°. This precision matters for automotive exhausts, hydraulic lines, and HVAC piping, where alignment affects fit and fluid flow.

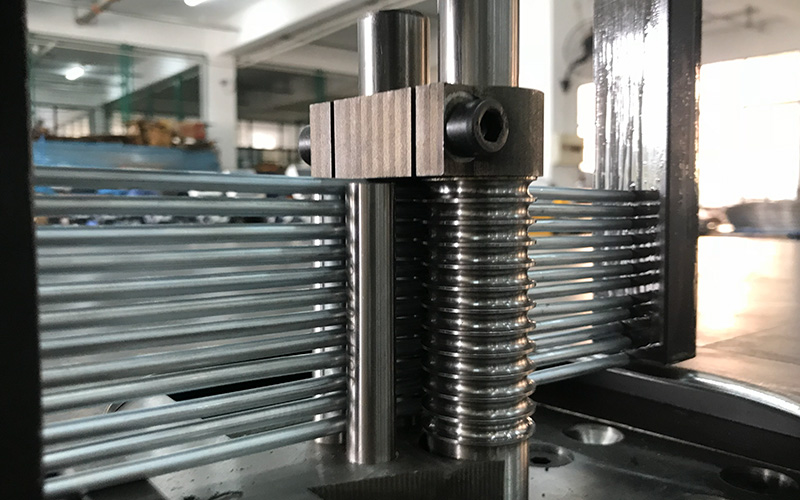

Some machines include mandrels—solid or ball-type rods positioned inside the tube. The mandrel keeps the inner wall from wrinkling when tight bends are made. In practice, this means tubes can maintain equal wall thickness around the bend, which improves fatigue life and sealing accuracy in high-pressure systems.

Rolling and Profiling Machines

Rolling and profiling machines shape tube cross-sections and large-radius curves through continuous passes between rollers. Unlike benders, they introduce gradual change instead of fixed-angle deformation. Three-roll angle rollers arrange the rolls in a pyramid pattern, which distributes stress evenly and avoids flattening.

Because the process exerts lower localized force, it works well for larger diameters and structural tubing used in architecture and infrastructure. Roll profiling lines can also form square, rectangular, or custom profiles by adjusting roller geometry.

In many setups, the rolling machine operates after welding or extrusion. By applying pressure across the full circumference, it refines roundness and surface finish. For the user, this translates to tubes with consistent diameter and smoother fit during assembly, reducing post-processing steps like grinding or reaming.

Specialized Tube End Forming Equipment

Tube end forming equipment modifies tube ends to allow joining, sealing, or connection with other parts. Common operations include expanding, reducing, flaring, and beading. Each changes diameter or edge shape without disturbing the tube centerline.

For example, beading adds a raised ring near the end to hold a hose under pressure. Expansion enlarges the end so another tube can nest inside for welding or brazing. Flaring forms a conical lip that creates a compression seal when bolted into a fitting.

Machines achieve these shapes through hydraulic or mechanical tooling that moves axially into the tube. The precise motion ensures uniform wall flow and maintains circular integrity. In industrial use, this accuracy prevents leaks and ensures reliable mechanical coupling in systems carrying liquids, gases, or thermal fluids.

Applications and Industry Considerations

Tube forming machinery supports a wide range of industries that rely on metal tubes for structure, transport, and precision systems. The choice of machine and process depends on the material, end-use conditions, and production scale. Accurate matching between material type and machinery capability allows consistent results across high-stress sectors such as automotive, aerospace, and construction.

Metal Tubes in Construction and Automotive

Metal tubes are used in building frames, pipelines, and vehicle components because of their mechanical strength and shape consistency. In construction, carbon steel and stainless steel tubes form load-bearing sections and conduit systems. These tubes must meet structural standards such as ASTM A500 or EN 10210 to ensure uniform wall thickness and dimensional accuracy.

In the automotive sector, machines form round, square, and elliptical tubes used for chassis, exhausts, and suspension systems. Cold forming and seamless processing are preferred when components must tolerate vibration and thermal stress. For instance, a seamless 4130 chromoly steel tube resists cracking under dynamic loads because no weld seam weakens its structure.

For manufacturers, this means fewer rejected parts and longer equipment life, especially during high-volume production runs.

Machinery Requirements for Different Materials

Different metals react differently under stress and temperature, which affects forming methods. Aluminum tubing, for example, requires controlled forming pressure to prevent surface marking. Machines that use servo-driven rollers with variable force settings can adapt to its lower hardness. For stainless steel, resistance to deformation makes multi-stand roll forming machines necessary. These machines progressively shape the tube using multiple stations to distribute stress and maintain precision.

Copper and brass tubes, common in HVAC and plumbing systems, demand smooth forming dies to prevent micro-cracks and leaks. When the machinery includes lubrication and cooling circuits, it keeps temperature rise minimal, preserving grain structure. In practical terms, selecting the correct processing setup reduces waste material and improves joint reliability in the final assembly.

Selecting Machinery for Specific Applications

Each application benefits from machinery tailored to its tolerance and throughput needs. A hydraulic end forming machine is suitable when precise flaring, expanding, or reducing is required, such as in aerospace fuel lines. By using programmable pressure control, it ensures repeatable geometry within ±0.1 mm, which is critical for tight-fitting assemblies.

In contrast, CNC-controlled tube benders serve producers who need rapid changeovers between designs. Because the machine stores multiple bending programs, it supports flexible production for furniture or custom exhaust systems. For mass manufacturing, integrating automation and robotic handling lowers labor costs and keeps variation minimal.

For the user, this means greater consistency across batches and simplified maintenance, since modern machines incorporate predictive diagnostics that monitor wear patterns in real time.

FAQs

Tube fabrication involves specialized machines that bend, form, or cut metal tubes to precise dimensions. Understanding how these systems differ by design, condition, and purpose helps engineers select equipment that matches production accuracy, cost, and material needs.

How does a CNC tube bender differ in functionality from other tube processing machines?

A CNC tube bender uses computer numerical control to automate the bending sequence through programmed angles, rotation, and feed lengths. Because of this, it executes complex multi-plane bends with consistent tolerances unde ±0.1°.

Manual or hydraulic benders rely on operator adjustment and offer lower repeatability. The CNC system replaces mechanical stops with servo-driven axes and sensors that correct each bend in real time. For the user, this means predictable accuracy across high-volume parts such as automotive exhausts or aerospace frames.

Other tube processing machines—such as end formers, cutters, or swagers—alter tube shape or finish rather than bend geometry. CNC bending complements those machines by ensuring dimensional control before further forming steps.

Are used tube forming machines as reliable as new ones for industrial applications?

Used tube forming machines can remain dependable if their mechanical systems, control software, and hydraulic circuits are maintained within calibration standards. Reliability depends on measurable wear factors such as ball-screw backlash and ram pressure accuracy rather than age alone.

A refurbished draw bender, for instance, may perform comparably to a new unit if its dies, mandrel shafts, and drive belts are replaced and re-aligned to factory tolerances. In practice, a verified maintenance record and test sample output provide the clearest evidence of usable life.

For continuous production or high-tolerance work, however, new machines often integrate motion controllers with faster interpolation rates and tighter synchronization between axes. That improvement directly reduces cycle time and tool wear.

What are the considerations when choosing machinery for precision tube manufacturing?

Key factors include material type, wall thickness, required bend radius, and the dimensional tolerance specified by the end product. A machine designed for stainless steel, for example, needs mandrel and die materials with higher hardness (around 60 HRC) to resist galling.

The desired accuracy determines whether a CNC-controlled or hydraulic system is appropriate. CNC machines store bend programs and adjust automatically for springback compensation, making them suitable for repeat runs. In contrast, manual setups suit short-batch fabrication where flexibility matters more than precision.

Power requirements, tooling availability, and integration with measurement systems also influence the choice. For the operator, aligning machine capability to product geometry not only ensures consistent output but also reduces scrap and setup time.

Want to Know More About Our Products?

View All Products Now