Differences Between a Tubing Roller and a Tube Processing Machine: Key Functions and Applications

A tubing roller shapes metal tubes into smooth curves or circles, while a tube processing machine performs multiple steps like cutting, bending, end forming, and welding to create finished tube products.

Both machines work with metal tubes, but their roles in manufacturing are pretty different. One focuses on forming; the other handles full-spectrum processing.

In modern production, you’ll see both tools in industries like construction, automotive, and energy manufacturing. Tubing rollers use controlled roller pressure to form consistent bends without flattening.

Tube processing machines integrate several mechanical operations to prepare tubes for final assembly. It’s easy to see why manufacturers sometimes mix the two up—they both deal with tube shaping.

Knowing how their functions diverge helps you pick the right system for your project’s efficiency and scale.

What Is a Tubing Roller?

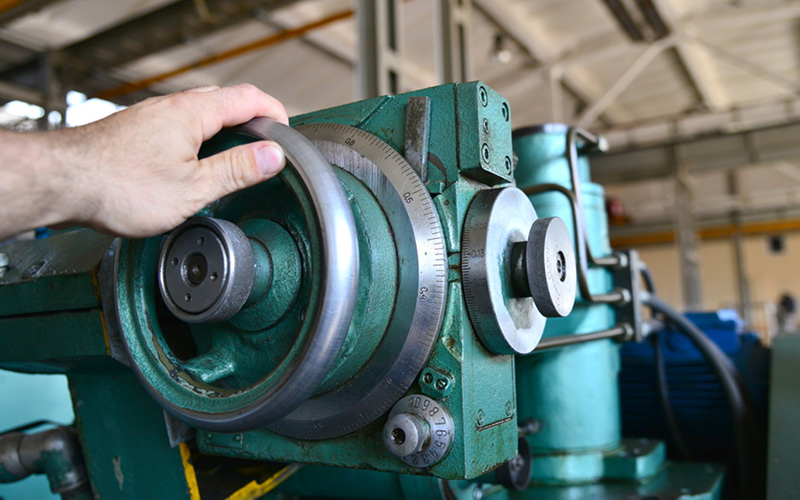

A tubing roller is a mechanical tool that bends or curves metal tubes and pipes into round or arched shapes. It uses a set of rollers to apply pressure gradually, shaping the metal without crushing it.

This lets you bend tubing consistently, usually without needing heat. Basic tubing rollers have three rollers: two on the bottom for support, and one on top that applies pressure.

You feed the tube between the rollers. Turning the handle or activating the motor moves the tube and forms a smooth curve.

The top roller adjusts to control the bend’s radius. There are a few types of tubing rollers out there:

- Manual rollers—good for small projects and hand cranking.

- Motorized rollers—these use electric or hydraulic power for bigger or thicker tubes.

- Adjustable-die rollers—they handle different tube shapes, like round, square, or even flat stock.

People often choose tubing rollers for fabrication, construction, or automotive work. Since the rollers keep the force uniform, the machine forms precise arcs for things like roll cages, railings, and metal frames.

What Is a Tube Processing Machine?

A tube processing machine is industrial equipment that shapes, forms, or finishes metal tubing through controlled mechanical steps. It tackles jobs like bending, cutting, end forming, or welding to get tubes ready for manufacturing.

These machines use a system of rollers, dies, and clamps to guide and shape the material. Some models run on hydraulic or electric drives, keeping pressure steady so they can handle steel, aluminum, and other metals.

Unlike a simple roller, which mainly bends a tube into a curve, a processing machine manages several fabrication stages. It might flatten ends, punch holes, or join sections using Electric Resistance Welding (ERW) technology.

- Forming: Bends or shapes a metal strip into a round or rectangular tube, making a seamless tube shape.

- Cutting: Trims tubing to length for straight, clean edges.

- Welding: Joins edges of rolled metal into a solid seam, giving you continuous welded pipe.

- End forming: Expands, reduces, or flares tube ends for ready-to-fit connections.

You’ll find tube processing machines in construction, automotive, and HVAC production lines. They keep shapes and dimensions uniform, so each tube fits into larger assemblies without much fuss.

Direct Comparison: Tubing Roller vs Tube Processing Machine

A tubing roller shapes metal tubes into curved or circular profiles. A tube processing machine, on the other hand, handles broader tasks like cutting, bending, end forming, and shaping.

These machines differ in purpose, precision, and investment scale, which affects how they fit into a workshop’s workflow and goals.

Functionality Comparison

A tubing roller uses three rollers in a sort of pyramid setup to curve tube or pipe stock. The operator feeds the material between the rollers and tweaks the pressure to get the desired radius.

It’s best for making arcs, rings, and big sweeps in steel, aluminum, or stainless tubing. A tube processing machine does a lot more. Depending on setup, it can cut, deburr, bend, flatten, expand, or notch tubes.

These machines often use servo or hydraulic controls for multi-step processing. Tubing rollers are great for forming consistent curves, while tube processing equipment supports complete fabrication steps.

Precision and Repeatability

Tubing rollers rely on mechanical pressure and manual adjustments, so repeat accuracy isn’t always perfect. The result depends on the operator’s skill, material springback, and how steady the pressure is.

For small runs or where exact dimensions aren’t crucial, this is usually fine. Tube processing machines use programmable systems and matched dies for repeatable results.

Servo motors or numeric controls keep bending angles and cut lengths consistent. Thanks to these controls, you can keep tolerance variation under ±0.5 mm on most setups.

If you need parts to fit into assemblies or production lines, repeatable performance matters. A tubing roller works for most custom jobs, but a processing machine brings dimensional reliability for batches of identical components.

Production Speed and Efficiency

A tubing roller moves as fast as the operator does. Rolling a section usually means several passes, adjusting pressure each time until you hit the right radius. This approach favors flexibility over speed.

You can switch materials quickly, but you won’t match automated throughput. Tube processing machines use automated feeds and integrated tooling stations, so tasks like cutting, bending, and end forming all happen in one go.

Hydraulic or servo motion lets you run continuously with barely any downtime. If you’re working on prototypes or architectural pieces, a tubing roller fits the bill. For high-volume manufacturing, tube processing machines make more sense—they keep parts flowing and cut down handling time, even if setup takes longer.

Skill and Operator Requirements

Operating a tubing roller takes manual control and a good eye. You adjust rollers bit by bit, judging the curve by sight or using templates.

Experience helps avoid oval deformation or flattening, especially on thin-wall tubing. The process leans more on craft than technology.

Tube processing machines cut down on human variation. Operators program parameters through a control panel and watch system feedback. The heavy lifting—forming or cutting—happens automatically under preset conditions.

Once the machine’s set up, minimal training keeps things running smoothly. Still, skilled setup techs make or break automated runs. They need to pick the right tooling, check alignment, and calibrate pressure. So, while day-to-day use is simpler, getting things started is more technical than with a hand-operated roller.

Cost and Investment Level

A manual or motorized tubing roller is a lower-cost buy. Entry-level models start in the low thousands, depending on roller size and drive style. Maintenance mostly means roller wear and a little gearbox lube.

For small shops, it’s a practical way into tube forming. A tube processing machine is a bigger investment. Systems with multiple forming heads or CNC integration can run from tens to hundreds of thousands.

These costs cover automation, precision drives, and multi-function capability. Tubing rollers typically cost $1,000–$6,000, with low maintenance and short setup times, but higher manual labor. Tube processing machines range from $30,000–$250,000+, need more maintenance and setup, but lower labor costs since they’re automated.

Choosing between them really depends on your production scale, precision needs, and payback time—not just the sticker price.

Use Case Scenarios: Which Machine Should You Choose?

Each machine fits a different purpose, depending on the work type, production scale, and precision you need. Your choice really comes down to material thickness, shape complexity, and what you want out of the finished tube.

When a Tubing Roller Is the Better Choice

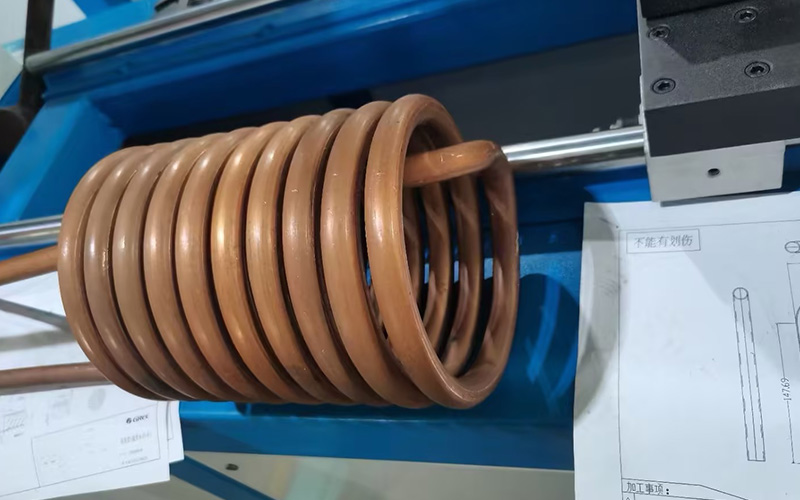

A tubing roller is ideal for projects focused on shaping tubes into smooth curves or coils without major deformation. It’s perfect for fabricators building frames, railings, or structural supports where you need uniform bends.

The machine uses mechanical rollers to apply steady pressure, so you get predictable arcs along the tube’s length. Shops working with steel, aluminum, or copper tubing in small to medium runs often choose this tool.

Since tubing rollers don’t need a lot of setup, you can switch between projects quickly. That’s handy for custom fabrication, light manufacturing, or prototyping. One big plus: less material waste. The rolling process keeps the tube’s diameter and wall thickness, so there’s less rework.

For industries that want flexibility and quick turnaround on low-volume jobs, a tubing roller offers a solid balance between control and simplicity.

When a Tube Processing Machine Is the Better Choice

A tube processing machine shines when your project needs multiple operations on the same tube—cutting, bending, punching, or end-forming, for example. These machines combine precision tools to do sequential steps, boosting accuracy, throughput, and repeatability.

They’re a good fit for large-scale production—think automotive, aerospace, and hydraulic system manufacturing—where tolerances are tight. Thanks to integrated controls and automation, you can keep dimensions consistent and reduce manual work.

If you’re shaping complex parts or need the tube to integrate with machined components, this system just works better. In real-world settings, a tube processing machine helps where speed, precision, and integrated workflows really matter for output quality and unit cost.

Summary of Key Differences

A tubing roller shapes metal tubing into smooth curves or coils by rotating dies. It forms the material gradually, using roll pressure instead of stretching or compressing things too much.

On the other hand, a tube processing machine takes care of several jobs—cutting, bending, forming, or end-finishing—right inside a single system.

The main difference? A tubing roller focuses on radius formation. Meanwhile, a tube processing machine handles dimensional preparation and shaping.

Adjusting the center roll on a tubing roller lets you create different bend radii. With a processing machine, you swap out tooling or dies to get each operation just right.

You’ll usually see tubing rollers in fabrication shops making frames or rings where they need consistent curvature. Tube processing machines are more at home on production lines, where the job demands precise preparation before assembly or welding.

So, which one do you pick? It really comes down to your goal—are you after smooth curves, or do you need a machine that can handle all the tube modification tasks from start to finish?

FAQ

Can a tubing roller replace a tube processing machine?

No, a tubing roller can’t take the place of a tube processing machine. It bends or curves metal tubes with three rollers to reach a certain radius, but that’s it.

You won’t find it cutting, welding, or sizing tubing. Tube processing machines handle those jobs—cutting, end forming, and sometimes even welding. Each machine really has its own job in the whole production setup.

Is CNC tubing rolling the same as tube processing?

They’re not the same thing. CNC tubing rolling uses computer controls to automate the bending process, which helps with consistency and repeatability.

Tube processing, though, covers a bunch of different steps. That could mean cutting, measuring, deburring, or forming, and these usually happen before or after bending.

Which industries use both machines together?

You’ll see both machines in fabrication shops, automotive plants, and places that build construction equipment. Rolling creates those curved shapes for frames or supports.

Processing machines get the tubes ready or finish them up for assembly. It’s not uncommon to see both on the same shop floor.

How does material type affect machine choice?

Material properties—like how hard or thick the tube is—change how you set up the machine and which rollers you pick. Stainless steel, for example, usually needs more pressure and tougher rollers.

Aluminum bends a lot easier, so you don’t need as much force. It’s all about matching the right setup to the metal you’re working with.

Want to Know More About Our Products?

View All Products Now