About BOBO

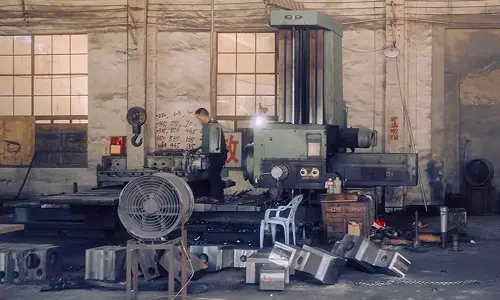

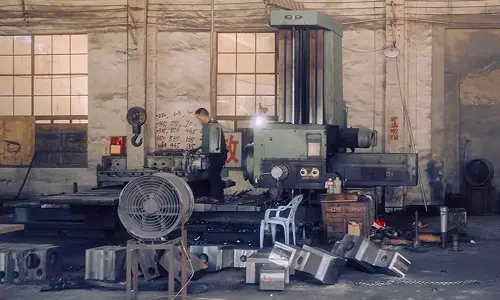

Old Factory

Modern Workshop

Modern Workshop

Modern Workshop

Old Factory

Old Factory

Modern Workshop

Modern Workshop

Modern Workshop

Old Factory

Global Services: Seamless Solutions

Professional Team Service

Since the establishment of the international trade department in 2004, the equipment has exported to a wide range of the countries worldwide and accumulated profound foreign trade experience, and 70% of the company’s employees have more than 5 years of foreign trade background.

Pre-Sales Service

BOBO Machine offers comprehensive pre-sale support through OEM & ODM services, tailored line design, and technical consultation. Whether you need custom-built machines or a complete solution for specific applications, such as our CNC coil tube straightening, cutting, bending, and end-forming system, we help you plan and configure the right setup. Backed by real case studies and precision standards, our pre-sale service ensures your equipment is optimized for performance, layout, and capacity before production begins.

During-Sale Service

At BOBO, we offer tailored support during the sales process to ensure you choose the right pipe processing equipment for your needs. We provide machine specifications, layout drawings, and demo videos to help you understand setup and operation in advance. For installation preparation, our team offers remote guidance via calls, emails, or video meetings to assist your technicians step by step.

After-Sales Service

BOBO provides comprehensive after-sales support including a 12-month warranty, core component replacement, and long-term maintenance guidance. Customers can choose from three setup service levels—from online video support to on-site installation by our engineers. With both remote and local service options, we ensure your equipment performs reliably and efficiently after delivery.

Doing What Others Cannot, Doing What

Others Will Not

Tube Processing Machines

Pioneer of Domestic Substitution

Industry-Academia Collaboration

11% High R&D Investment

Flexible Customized Production

Connect Online • Engage Offline