Industry

Fin and Tube Machinery

Simple Partner Steps

Communication

Order Confirm >>Production

Delivery >>On-Site Set up

Operation >>Home Appliance Industry Market for Fin & Heat Tube Processing Machines

HVAC System

Refrigerator

Washer&Dryer Appliance

Water Heater

Floor Heating System

Smart Home Appliance Radiator

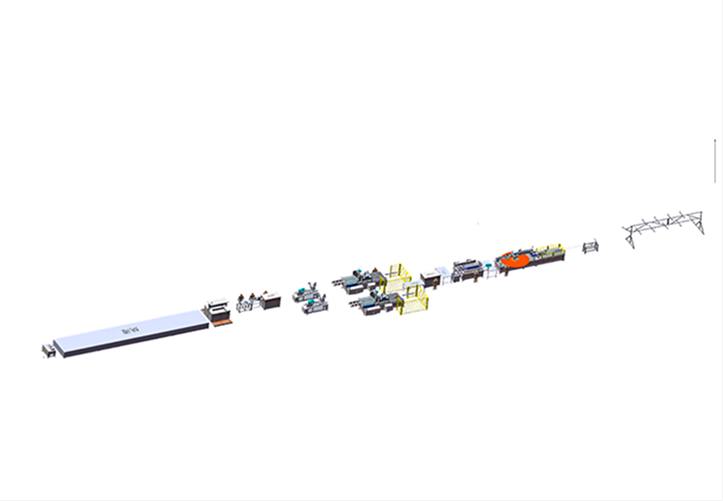

Tubing Machines for HAVC Radiator Processing

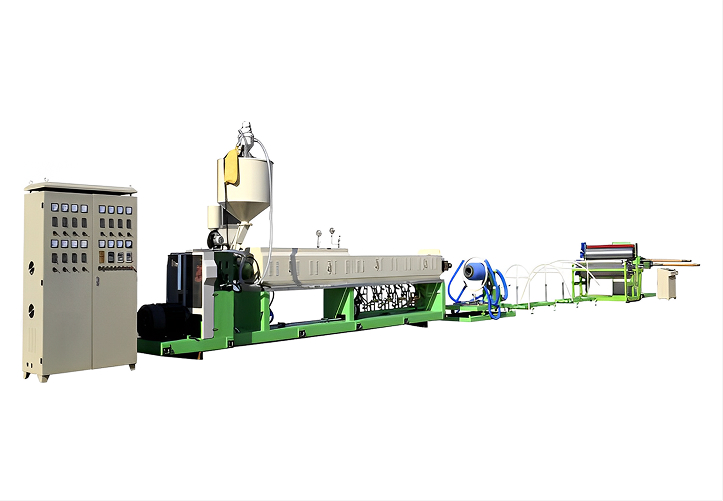

Air Conditioning Insulation Tube Production Line

The AC Insulation Tube Line can process different foam sheet width and thickness according to customer requirement. It uses low-density polyethylene (LDPE) resin as the raw material, which is fed into a high-efficiency extruder with a 55:1 L/D screw. The process incorporates anti-shrinking and foaming agents under high pressure, producing foam pipes that are then cooled and extruded for use.

Insulated Foam Layer & Connecting Tube Producing Processes

Material Feeding Unit

Extruder

Foaming & Anti-shrinkage Agent Injection

Cooling

Hauling & Winding

Control Cabinet

PE Foam Pipe Covering

Decoiling

Straigntening and Cutting

Insulation Tube Inserting

Nut Assembling & Tube End Flaring

Re-coiling Machine

Aluminum Tube Serpentine Bender

CNC Pneumatic 3D Tube Bender

G-type Condenser Bending Machine

Tubing Machines for Refrigerator Condenser

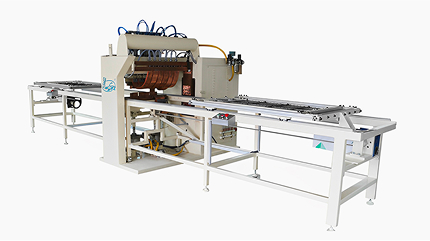

Refrigerating Condenser Production Line

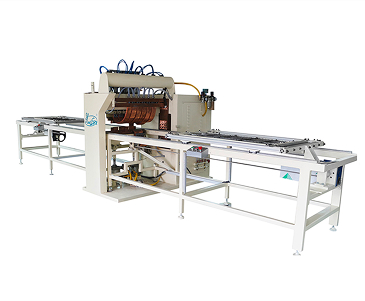

The welding position of WOT wire on condenser production line could be set at random. This cantilever type spot welding machine adopts 6 welding heads and automatic feeding system. It is designed with double sides single layer feeder system.

Refrigerator Condenser Producing Processes

Wire Cut to Length

Steel Tube Cut to Length

Steel Tube Bending

Wire on Tube Welding

Condeser Folding and Coiling

Fin Evaporator End Tube Bending Machine

Manual U Bending Machine M-1250mm

Automatic Hairpin Tube Making Machine

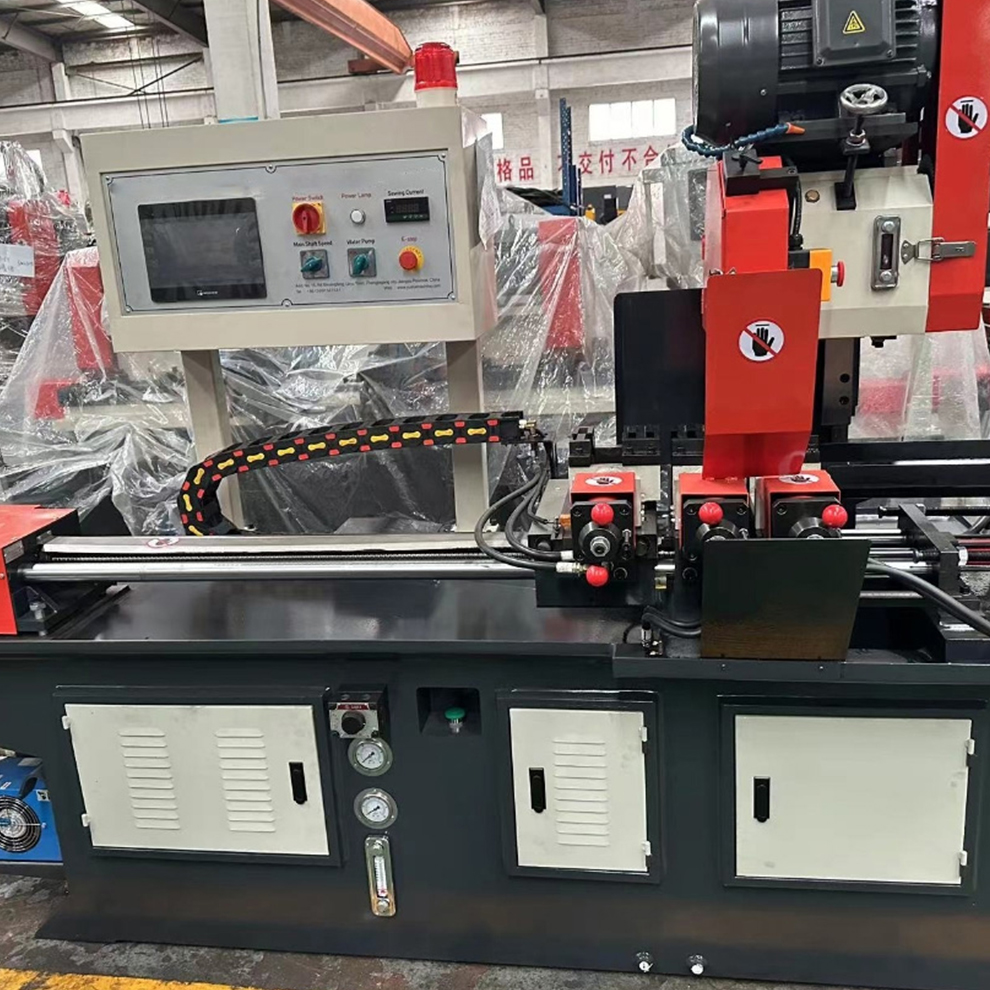

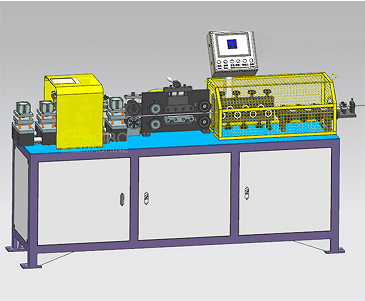

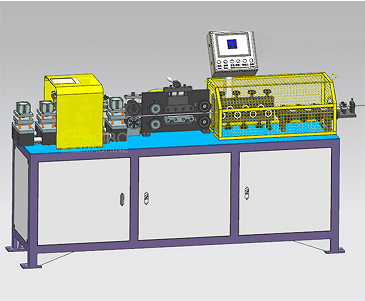

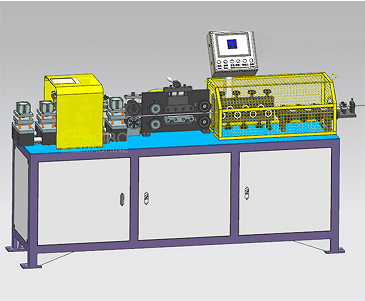

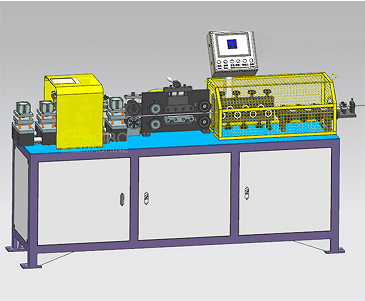

Steel / Bundy Tube Straightening & Chipless Cutting Machine

Fin Tube Machines for Home Washer & Dryer Evaporator

Inclined Fin Evaporator Production Line

The entire Fin Tube Evaporator Production Line adopts a single piece flow circulation mode, with a rhythm driven production, achieving maximum output with the most streamlined personnel. Save labor, reduce costs, and improve production efficiency.

Evaporator Producing Processes

Fin Stamping

Tube Serpentine Bending

TubeTwisting &End Flattening

Tube Folding

Tube Resistance Welding

Fin Alignment & Tube Inserting

Leakage Water Testing

Reservoir Tube Bending

Argon Welding

Side Plate Assembling

Evaporator End Tube Bending

Copper / Aluminum Tube Straightening And Cutting Machine

Integrated Tube Straightening-Cutting And End Forming Machine

Capillary Tube Straightening And Stripping

Automatic Straight Tube Saw Cut To Length Machine

Fin Tube Machines for Floor Heating System

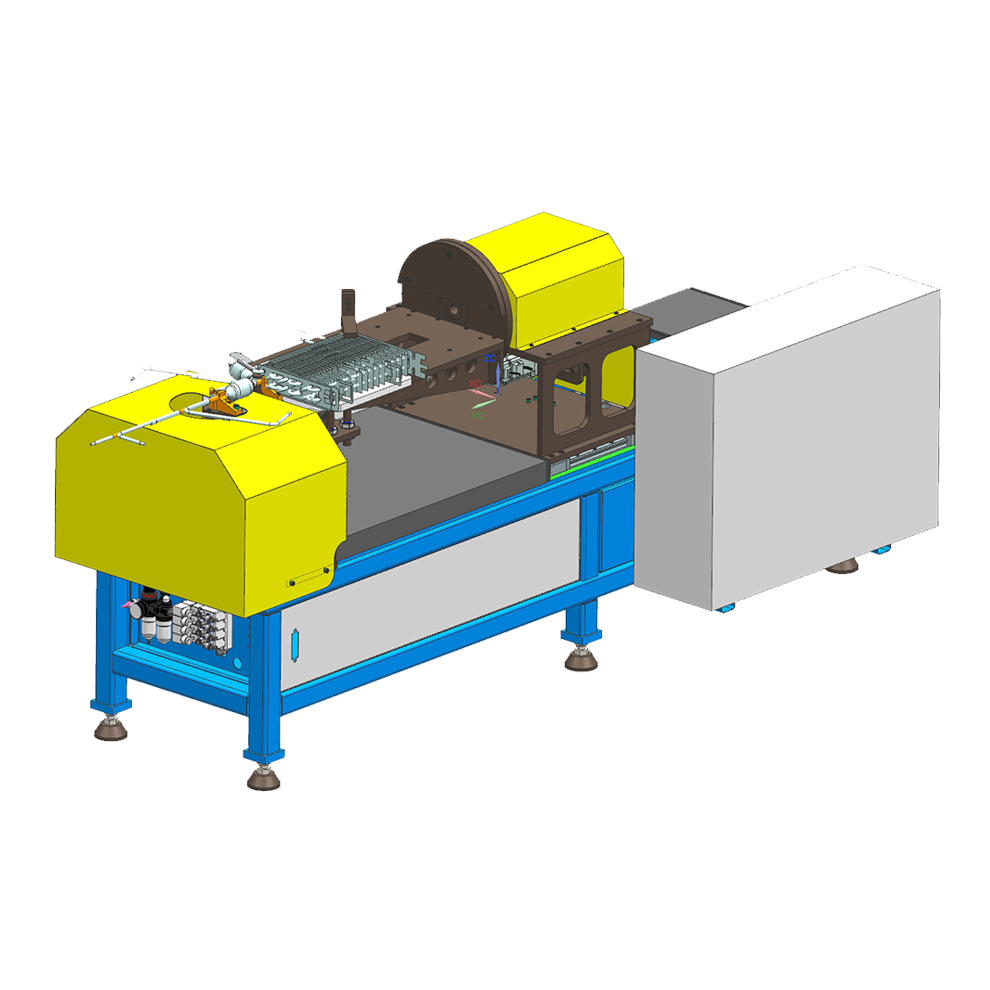

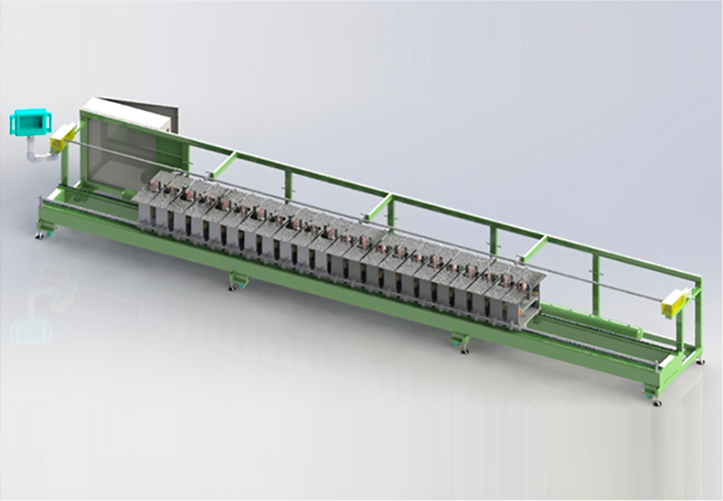

No-frost Vertical Fin Evaporator Production Line

The Evaporator Production Line adopts touch screens as the setting operation interface and is centrally controlled by XC3 series PLC. The cylinder action is controlled by an electromagnetic valve to achieve continuous cyclic action during multi head bending.

No-Frost Evaporator Producing Processes

Tube Straightening & Cutting

Fin Stamping

Fin Alignment & Tube Expander

Tube End Cutting

Airproof Testing Tank

Tube End Bending

Evaporator Side Fixture Plate Assembling

Argon Welding

Fin Evaporator End Tube Bending Machine

Manual U Bending Machine M-1250mm

Automatic Hairpin Tube Making Machine

Steel / Bundy Tube Straightening & Chipless Cutting Machine

Get Free Quotation

Custom Fin Tube Machinery Line Services

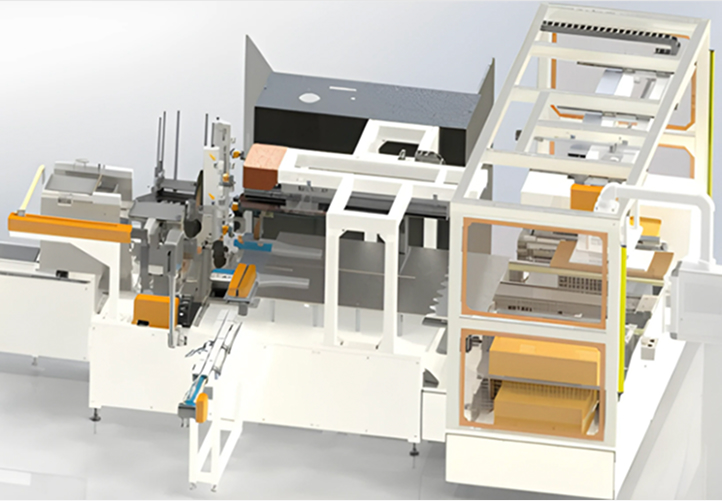

The automatic radiator core production line is from fin rolling to inserting flat tubes, auto-feeding the flat tubes gap, and also the side plates and main plate crimping assembly to finish the aluminum core.

Combined Craft Functions:

Precisions & Features:

OEM&ODM Services

3 Level Set up Services

12 Months Waranty

Certifications

FAQs

Other than home appliance industry, bobo machine also involved in 3C electronic heat sinker processing equipment, commercial and industrial heat exchanging processing machines, automobile radiator machinery, military and aerospace cooler producing lines.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. Install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.