What is a Cut-to-Length Machine?

A cut-to-length machine stands as a pivotal piece of equipment that ensures this precision by straightening and cutting materials such as tubes, wires, and sheets to exact specifications. These machines prove indispensable across various industries, particularly in the production of heat exchange systems where accuracy directly impacts performance. This article explores the technical intricacies of cut-to-length machines, detailing their operational principles, applications, and the diverse offerings from BoBo Machine, a leader in heat exchange equipment. With a focus on technical depth, we aim to provide engineers, manufacturers, and industry professionals with a comprehensive understanding of this critical technology.

What is a Cut-to-Length Machine?

A cut-to-length machine actively processes raw materials—typically metal tubes, wires, or sheets—into precise lengths required for downstream manufacturing. Unlike general cutting tools, these machines integrate straightening and cutting functions into a single automated process, ensuring consistency and accuracy. In the context of BoBo Machine, the focus narrows to tubes and wires, especially those integral to heat exchange applications. By delivering exact cuts, these machines eliminate variability, making them essential for industries demanding tight tolerances.

The significance of a cut-to-length machine lies in its ability to streamline production. For instance, in heat exchanger manufacturing, tubes must align perfectly within specified dimensions to optimize heat transfer. Even minor deviations compromise efficiency, underscoring the machine’s role in maintaining high standards.

How Does a Cut-to-Length Machine Work?

A cut-to-length machine operates through a sequence of precisely engineered steps, each contributing to the final output’s accuracy. Below, we break down the process:

1. Material Feeding

The machine begins by actively feeding the material into its system. A sophisticated feeding mechanism, often equipped with sensors, ensures proper alignment and consistent material flow. This step sets the foundation for subsequent operations, preventing misalignment that could affect cut precision.

2. Straightening Process

Next, the material passes through a series of straightening rollers. These rollers actively apply pressure from multiple angles, eliminating bends, kinks, or twists. The roller configuration adapts to the material type—robust designs handle steel wires, while finer adjustments protect softer metals like copper or aluminum. This straightening ensures the material enters the cutting phase in an optimal state.

3. Cutting Mechanism

Once straightened, the material advances to the cutting mechanism. The machine employs various cutting methods based on material properties and application needs:

- Saw Cutting: A blade actively slices through the material, suitable for thicker or harder substances.

- Shear Cutting: A scissor-like action severs the material, offering speed for certain applications.

- Chipless Cutting: Advanced techniques, such as rotary or laser cutting, produce clean, debris-free cuts. This method excels in heat exchange applications where contaminants could degrade performance.

The choice of cutting mechanism directly influences cut quality and production efficiency, with chipless options gaining favor for their precision and cleanliness.

4. Control System

A computerized control system governs the entire process, ensuring each cut meets exact specifications. These systems actively monitor and adjust parameters, achieving tolerances within fractions of a millimeter. Programmable settings allow operators to store multiple cutting profiles, enhancing flexibility across production runs.

5. Additional Features

Many cut-to-length machines incorporate supplementary features. Integrated measuring systems actively verify cut lengths, while automatic lubrication maintains component longevity. Dust collection systems manage debris, particularly in saw or shear cutting setups, ensuring a clean workspace.

Together, these components create a seamless workflow, transforming raw materials into precisely cut pieces ready for assembly or further processing.

Applications of Cut-to-Length Machines in Heat Exchange Systems

In heat exchange systems, a cut-to-length machine directly impacts product performance. Heat exchangers rely on tubes cut to exact lengths to facilitate efficient heat transfer between fluids. Variability in tube length disrupts flow dynamics, reducing efficiency and potentially leading to system failure. Consequently, manufacturers depend on these machines to uphold rigorous standards.

Precision in Action

Consider a typical heat exchanger production line. Copper or aluminum tubes, often used for their thermal conductivity, require precise cutting to fit within the exchanger’s framework. A cut-to-length machine ensures each tube matches the design specifications, minimizing gaps or overlaps that could impair heat transfer. Moreover, in high-volume production, the machine’s automation reduces labor costs and accelerates throughput.

Beyond Heat Exchange

While heat exchange systems represent a primary application, cut-to-length machines serve broader industries. Steel wire cutting supports construction and automotive sectors, while capillary tube processing aids refrigeration and medical equipment manufacturing. This versatility underscores the machine’s value across manufacturing domains.

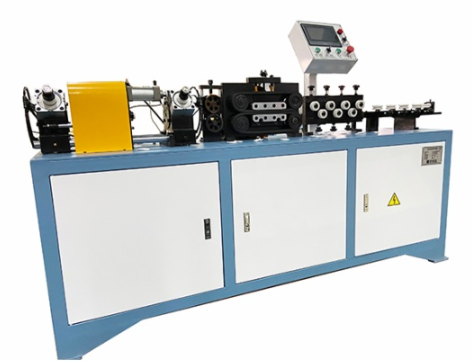

Types of Cut-to-Length Machines Offered by BoBo Machine

BoBo Machine actively caters to diverse manufacturing needs with an extensive lineup of cut-to-length machines. Below, we highlight key products, emphasizing their technical features and applications.

1. Steel Wire Straightening and Cutting Machine

- Material: Steel wire

- Features: Heavy-duty rollers withstand steel’s rigidity, paired with a high-precision cutting system.

- Applications: Produces uniform steel wire lengths for industrial uses, such as reinforcement in construction.

2. Copper and Aluminum Tube Straightening and Cutting Machine

- Material: Copper and aluminum tubes

- Features: Gentle straightening prevents deformation, with optional chipless cutting for clean edges.

- Applications: Supplies heat exchanger tubes, ensuring burr-free cuts critical for fluid flow.

3. Capillary Tube Straightening and Stripping Machine

- Material: Capillary tubes

- Features: Specialized rollers handle small diameters, with an integrated stripping function for coating removal.

- Applications: Prepares capillary tubes for refrigeration systems, where precision and cleanliness are paramount.

4. Multi-Station Tube Straightening and Cutting Machine (MKA-20-2-2)

- Material: Various tubes

- Features: Multiple stations process tubes simultaneously, boosting throughput.

- Applications: Ideal for high-volume production, reducing bottlenecks in large-scale manufacturing.

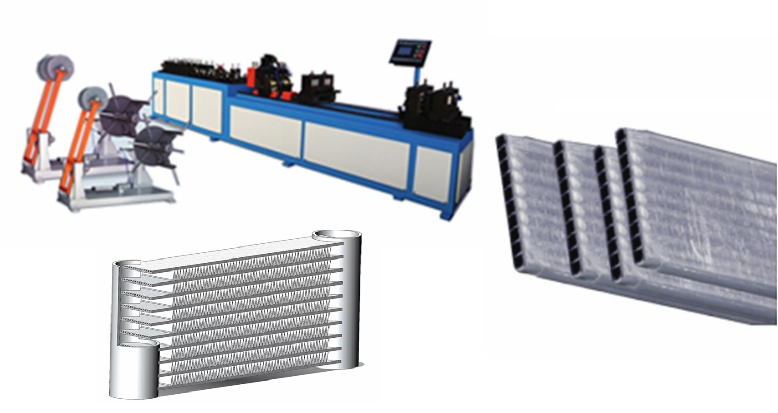

5. Flat Tube Straightening and Chipless Cutting Machine

- Material: Flat tubes

- Features: Chipless cutting ensures smooth edges, with precise straightening for flat profiles.

- Applications: Supports specialized heat exchangers requiring flat tube configurations.

Enhanced Focus: Integrated Capillary Tube Cutting and Bulging Machine

Among BoBo Machine’s offerings, the Integrated Capillary Tube Cutting and Bulging Machine stands out for its multifunctionality. This machine not only straightens and cuts capillary tubes but also performs bulging—an operation that expands tube ends for fitting or sealing purposes. By consolidating these processes, it reduces equipment footprint and production time, making it a standout choice for manufacturers seeking efficiency without compromising precision.

Benefits of Using Cut-to-Length Machines

Cut-to-length machines deliver measurable advantages that enhance manufacturing operations:

- Enhanced Efficiency: Automation actively reduces manual intervention, accelerating production cycles.

- Minimized Waste: Precise cuts optimize material usage, lowering costs and environmental impact.

- Superior Quality: Consistent outputs meet tight tolerances, reducing defect rates.

- Operational Flexibility: Diverse models handle various materials, adapting to specific production needs.

These benefits collectively elevate a manufacturer’s competitiveness, particularly in precision-driven sectors like heat exchange equipment production.

Choosing the Right Cut-to-Length Machine

Selecting a cut-to-length machine demands a technical evaluation of several factors:

- Material Compatibility: The machine must suit the material’s properties—steel requires durability, while copper demands finesse.

- Precision Level: Applications like heat exchangers necessitate high accuracy, often requiring chipless cutting.

- Production Scale: High-volume operations benefit from multi-station designs, while smaller runs may favor simpler models.

- Specialized Features: Features like bulging or stripping may be critical for specific processes.

BoBo Machine actively supports this decision-making process, offering expert guidance to match machines with customer requirements. Their extensive catalog ensures a solution for every scenario.

Maintenance and Care for Cut-to-Length Machines

Maintaining a cut-to-length machine ensures sustained performance and longevity. Key practices include:

- Regular Inspections: Actively monitor rollers, cutting mechanisms, and feeding systems for wear.

- Lubrication: Apply lubricants to moving parts, reducing friction and preventing breakdowns.

- Calibration: Periodically adjust the control system to maintain cutting accuracy.

- Cleaning: Remove debris from cutting and feeding areas to avoid malfunctions.

Technical Advancements in Cut-to-Length Technology

The evolution of cut-to-length machines reflects ongoing advancements in manufacturing technology. Modern systems integrate smart features, such as real-time monitoring and predictive maintenance alerts, to enhance reliability. Additionally, improvements in cutting mechanisms—like laser-based chipless cutting—push the boundaries of precision and cleanliness. BoBo Machine stays at the forefront of these developments, incorporating cutting-edge innovations into their product line.

Conclusion: The Critical Role of Cut-to-Length Machines

Ultimately, cut-to-length machines anchor precision manufacturing, particularly in heat exchange systems where accuracy defines success. These machines actively transform raw materials into components that meet exacting standards, driving efficiency, quality, and cost-effectiveness. BoBo Machine exemplifies this commitment with a robust portfolio tailored to diverse applications.

If you seek to elevate your manufacturing process with a high-quality cut-to-length machine, contact BoBo Machine today. Their expert team stands ready to deliver tailored solutions that enhance your production capabilities.

Meta Description: Explore the technical role of cut-to-length machines in manufacturing, focusing on heat exchange systems. Learn their operations, applications, and BoBo Machine’s advanced offerings in this detailed guide.

Want to Know More About Our Products?

View All Products Now