Heat Pipe vs Heat Sink: What’s the Processing Difference?

Thermal management is critical in electronics, aerospace, and energy systems. While heat pipes and heat sinks both dissipate heat, their manufacturing processes differ fundamentally due to distinct operational principles and structural complexities.

This blog deeply explores their processing differences, material choices, technical challenges, and cost implications.

1. Core Structural Differences Drive Manufacturing Divergence

Heat Pipes: Sealed, vacuum-tight systems with internal wicks and working fluids (e.g., water, acetone). Heat transfer relies on fluid phase change (evaporation/condensation) and capillary action

Heat Sinks: Solid metal structures (typically aluminum or copper) with fins. Heat dissipates via conduction and convection—no internal fluids or sealed cavities

2. Material Selection: Purity vs. Conductivity

Heat Pipes:

Container Materials: Ultra-pure oxygen-free copper (99.99%) for compatibility with working fluids and vacuum integrity. Stainless steel/aluminum for specialized applications (e.g., cryogenics)

Wicks: Sintered copper powder, mesh, or grooves. Require high porosity for capillary action

Fluids: Acetone, water, or liquid metals. Must be ultra-pure to prevent contamination

Heat Sinks:

Dominant Materials: Aluminum alloys (1060, 6063) for cost-effectiveness and extrusion ease. Copper for high-end applications (2× better conductivity but 3× denser)

Advanced Options: Diamond-embedded or copper-aluminum composites for extreme thermal loads

Material Comparison:

| Component | Heat Pipe Materials | Heat Sink Materials |

| Primary Structure | Ultra-pure Cu, SS, Al | Al alloys, Cu |

| Thermal Interface | Sintered Cu wicks, mesh | Solid fins/base |

| Thermal Enhancement | Working fluids (e.g., H₂O, acetone) | Fins, heat pipes (hybrid designs) |

3. Manufacturing Processes: Precision vs. Scalability

Heat Pipe Production (17+ Steps):

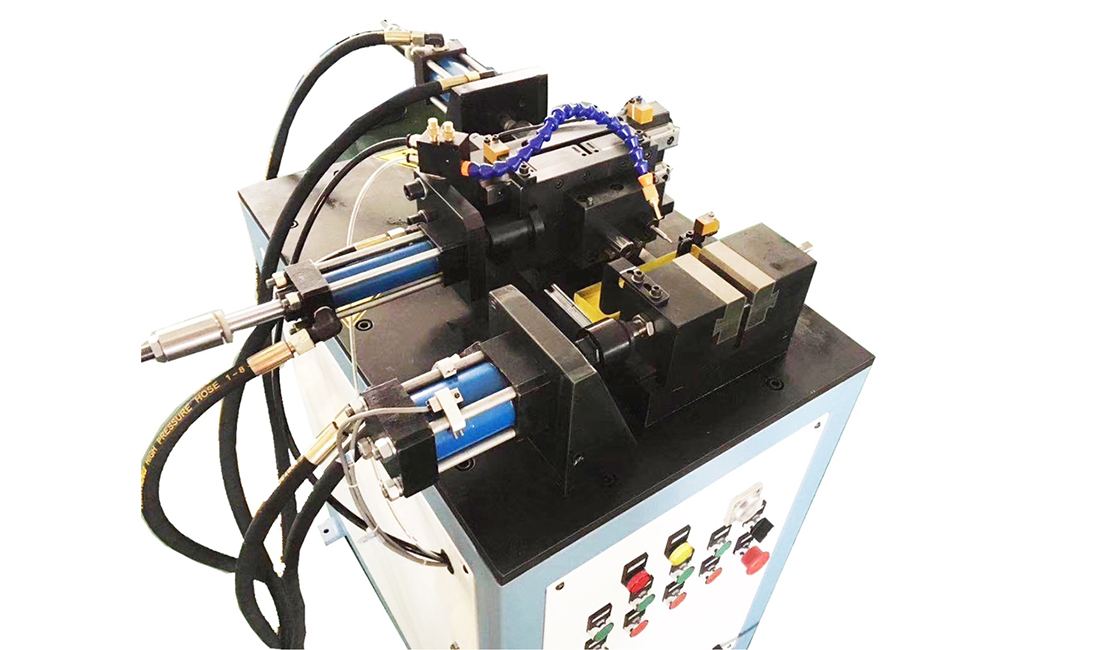

- Tube Preparation: Cutting copper tubes → ultrasonic cleaning → end reduction

- Wick Integration: Sintering copper powder at 800°C in H₂/N₂ atmosphere (16 hours)

- Sealing & Charging:

- Vacuum evacuation (-721 mbar average)

- Fluid injection (e.g., 36.6% acetone by volume) → final welding

- Testing: Accelerated aging, thermal cycling, leak checks, and burst tests

Heat Sink Production (4 Core Methods):

- Extrusion (80% market share): Forced molten aluminum through dies → cutting/finishing.

- Stamping: Sheet metal pressed into shapes. Low-cost, limited to thin profiles

- CNC Machining: For custom, high-precision designs. Costly but flexible

- Bonding: Combining copper bases with aluminum fins (epoxy/brazing). Balances cost/performance

4. Technical Challenges: Physics vs. Fabrication

Heat Pipes:

- Capillary/Viscous Limits: Wick design must overcome fluid flow resistance

- Leak Prevention: Vacuum integrity demands hermetic welds (helium leak testing <10⁻⁹ mbar·L/s)

- Fluid Contamination: Even trace impurities degrade performance

Heat Sinks:

- Fin Aspect Ratios: Tall, thin fins (e.g., 15:1 height/gap) risk deformation during extrusion

- Thermal Interface Gaps: Non-flat bases increase contact resistance—requires surface milling

- Corrosion: Aluminum oxidizes easily → anodizing essential

5. Cost Structure: Labor vs. Material

| Factor | Heat Pipe | Heat Sink |

| Material Costs | 40% (high-purity Cu/fluids) | 70% (bulk aluminum) |

| Labor/Equipment | 50% (vacuum system, sinter) | 20% (extrusion dies, CNC) |

| Rejection Rate | 10–15% (leak failures) | <5% (geometric defects) |

| Example Cost Driver | $500k vacuum chamber | $50k extrusion die |

6. Performance Synergy: Hybrid Designs

Embedding heat pipes into heat sinks enhances thermal spreading:

- Thermal Resistance: Copper-base heat pipe sinks achieve 0.118 K/W vs. 0.327 K/W for solid aluminum

- Power Handling: Vapor chamber bases dissipate 135W at 35°C ΔT, outperforming solid copper by 20%

7. Future Trends: Automation & Composites

- Heat Pipes: Aluminum replacements for copper to cut cost/weight (e.g., EVs)

- Heat Sinks: 3D-printed graphene/aluminum composites for optimized topology

Heat pipes demand precision fluid handling and sealing for phase-change efficiency, while heat sinks prioritize scalable forming techniques for maximal surface area. Understanding these differences empowers engineers to select, design, and innovate thermal solutions for tomorrow’s high-power electronics.

Want to Know More About Our Products?

View All Products Now