Hydraulic or Manual Tube Bender: Which One is Best for You?

Choosing between a hydraulic and manual tube bender depends on the size of the job, budget, and required precision. Hydraulic benders use pressurized fluid to create strong, consistent bends with less physical effort, making them ideal for heavy-duty or high-volume work. Manual tube benders rely on hand power, offering greater control and lower cost for small projects or occasional use.

Professionals in automotive, construction, and fabrication industries often compare these two types for factors like bending capacity, setup time, and ease of use. Both have clear advantages depending on the materials—steel, stainless steel, or aluminum—and the desired bend radius.

This guide explains how each type works, the differences that matter most, and when to choose one over the other. It draws on insights from experienced machinists and manufacturers to help anyone select the right bender for their specific needs.

What is a Hydraulic Tube Bender?

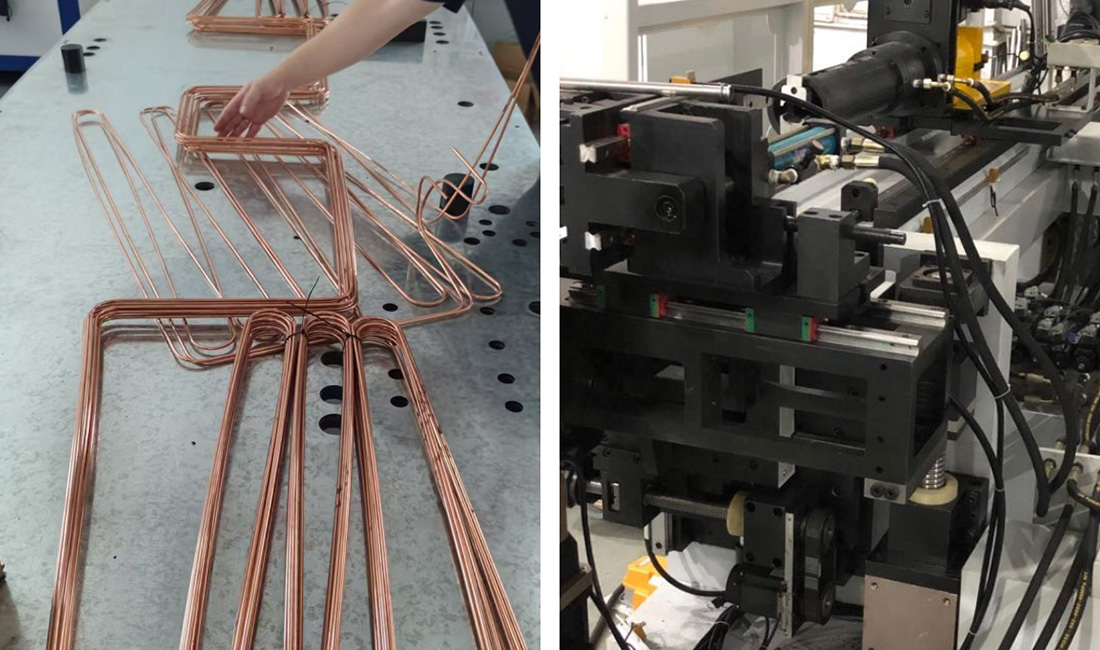

A hydraulic tube bender is a machine that uses hydraulic pressure to bend metal tubes or pipes into precise angles and curves. It applies controlled force through a hydraulic system, allowing for smooth, uniform bends without crimping or damaging the tube wall. These machines are commonly used in construction, automotive, and manufacturing industries where durability and accuracy are required.

Hydraulic benders operate efficiently when handling thick or large-diameter tubing made from steel, stainless steel, or other tough metals. They are valued for their consistency, which is essential in producing repeatable bends for high-volume fabrication and industrial use.

Below are advantages of hydraulic tube benders:

- Power and capacity: Hydraulic benders handle larger tube diameters and thicker materials that manual benders cannot manage.

- Precision: The hydraulic system controls bending pressure evenly, resulting in consistent, high-quality bends.

- Reduced physical effort: Operators expend less energy since the machine supplies most of the force needed for bending.

- Efficiency: Ideal for production environments that require frequent or complex bends.

Below are disadvantages of hydraulic tube benders:

- Higher cost: Hydraulic systems are more expensive to purchase and maintain than manual models.

- Maintenance: Leaks, worn seals, and fluid changes require periodic attention.

- Size and setup: These machines are heavier and less portable, limiting mobility for small workshops or field use.

- Complexity: Training or experience may be needed to operate safely and accurately.

What is a Manual Tube Bender?

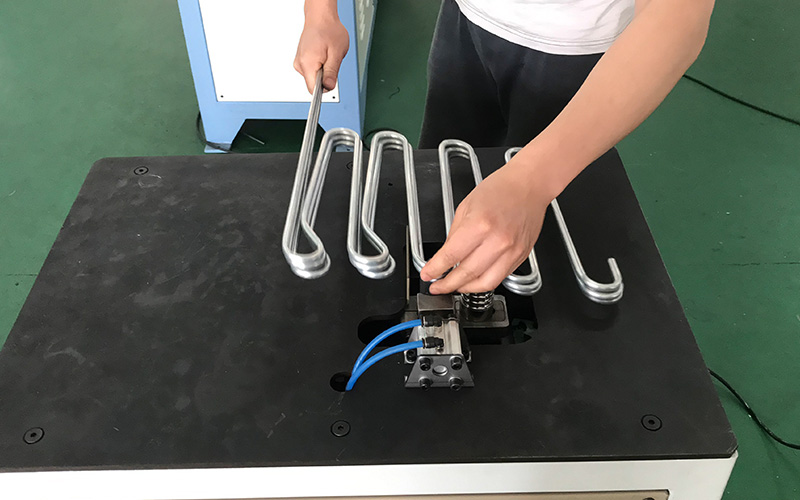

A manual tube bender is a hand-operated tool used to shape metal tubing or piping without damaging its structure. It works by applying mechanical force through levers or handles to form bends at specific angles. These tools are often used in small workshops, maintenance jobs, and low-volume fabrication where portability and control matter more than speed.

Manual benders require physical effort from the operator but provide direct control over each bend’s radius and angle. They are available in different sizes to handle materials such as steel, aluminum, or copper.

Below are advantages of manual tube benders:

- Affordable: Manual tube benders cost less than hydraulic models, making them ideal for smaller budgets.

- Portable: Most units are compact and easy to move, allowing use in tight or remote spaces.

- Precise Control: Operators can fine-tune each bend manually, reducing the risk of overbending.

- Low Maintenance: With fewer moving parts, upkeep is simple and inexpensive.

Below are disadvantages of manual tube benders:

- Labor-Intensive: Physical effort limits efficiency for large or thick tubing.

- Limited Capacity: They handle smaller diameters and softer materials best.

- Speed Constraints: Manual operation takes longer for repetitive production.

- Skill Requirement: Consistent results depend heavily on operator experience.

Hydraulic vs Manual Tube Bender: What are the Key Differences?

Hydraulic and manual tube benders perform the same function—shaping metal tubes—but they do so in different ways. Each type varies in operation, accuracy, and price, which affects how suitable it is for different projects.

How Each Bender Operates

Hydraulic systems rely on fluid power for consistent force, while manual units depend entirely on physical strength and leverage.

A hydraulic tube bender uses pressurized fluid to generate force that bends metal tubing. The operator controls this pressure through a pump or lever, which moves a hydraulic piston against the tube. This setup allows it to shape thicker or larger-diameter materials with minimal effort. Many workshop and industrial models include gauges and valves to help control bending angles and repeatability.

A manual tube bender works purely through human force. The operator pulls a handle or uses a ratcheting mechanism to bend the tube around a die. Since no hydraulic pressure assists the process, it works best for smaller tubes or softer materials such as aluminum. Manual designs are straightforward, portable, and require little setup or maintenance.

Precision and Power Comparison

Hydraulic benders provide greater bending power and are capable of forming tight, high-accuracy bends on thicker tubes. The steady hydraulic pressure reduces the risk of kinks or flattening in the material. These machines often include adjustable settings for bending radius and angle control, helping maintain consistent results across multiple parts.

Manual benders offer less raw strength but allow the operator more “feel” for the material during bending. This tactile control can improve precision in light-duty applications where small adjustments matter more than speed. For thick steel or high-strength alloys, however, manual models often struggle to deliver consistent angle accuracy without operator fatigue.

Cost

A hydraulic tube bender costs more to buy and maintain due to its fluid system, valves, and power components. Larger workshop units often require accessory pumps or oil tanks, which increase setup cost. Businesses invest in these machines for productivity and repeatable precision when handling multiple or thick-walled tubes.

A manual tube bender is far cheaper and usually costs a fraction of a hydraulic model. It has fewer parts and requires no external power. For hobbyists or small repair shops, the lower purchase and operating costs make it a practical option. The trade-off is slower operation and limited capacity for heavy tubing, which can increase labor time on larger jobs.

When to Choose Manual Tube Bender?

Manual benders are best suited for small-scale jobs or low-volume projects. They handle tasks like custom exhausts, furniture frames, and small repair work where precision matters more than speed. Because they are simple to set up and easy to transport, many workshops keep one for quick adjustments or prototype work.

Cost is another factor. Manual tube benders are more affordable and require minimal maintenance, making them useful for small businesses or hobbyists. They don’t need an external power source, reducing long-term expenses.

Operators should choose a manual tube bender when working with thin-walled or smaller-diameter tubing. For heavier materials or repeated tasks, switching to a hydraulic bender offers greater efficiency.

When to Choose Hydraulic Tube Bender?

Hydraulic models suit jobs that demand precision, speed, and repeatable results. It uses fluid pressure to shape metal tubes with controlled force. It helps fabricators bend larger or thicker materials that would be difficult to handle with a manual tube bender.

They reduce physical effort, so operators can complete more bends with less strain. Industries like construction, automotive, and aerospace often depend on hydraulic systems for their reliability in high-volume operations.

Compared to manual tube benders, hydraulic ones cost more and take longer to set up. Yet, once configured, they handle tasks faster and require less manual adjustment. This saves time on repetitive bends or when working with stainless steel, aluminum, or heavy-wall tubing.

A fabricator might prefer a hydraulic system when project size, workload, or precision justifies the higher price. For small-scale or simple bends, a manual tube bender remains practical, but hydraulic versions excel when power and consistency matter most.

Frequently Asked Questions

Is a hydraulic tubing bender worth it?

A hydraulic tube bender uses pressurized fluid to apply consistent force, making it effective for larger or heavy-duty jobs. It reduces manual effort and increases accuracy on repetitive bends.

It tends to cost more than a manual bender but saves time when working with thick-walled or high-strength materials. For users handling frequent or high-volume bending, the higher price often balances out through improved efficiency and reduced fatigue.

How does one determine the correct tube bender size for a specific project?

The correct size depends on the material type, tube diameter, wall thickness, and desired bend radius. Each bender model lists its capacity range, which ensures users select a machine suited to their application.

For example, a small manual bender might handle aluminum or copper tubing up to one inch in diameter, while a hydraulic unit can bend larger steel pipes with greater consistency. Matching the bender’s rated capacity to the pipe’s properties prevents damage to both the tool and the tubing.

What safety procedures should be followed when operating a tube bender?

Operators should inspect the machine before each use to confirm clean dies, secure connections, and proper alignment. Wearing safety glasses, gloves, and steel-toed shoes reduces the chance of injury from shifting or springing metal.

They should keep hands away from moving parts during motion and use stable work surfaces to prevent tipping. Following the manufacturer’s load limits and securing the work area ensure more accurate bends and safer operation.

Want to Know More About Our Products?

View All Products Now