Automatic Fin Alignment And Expanding Machine

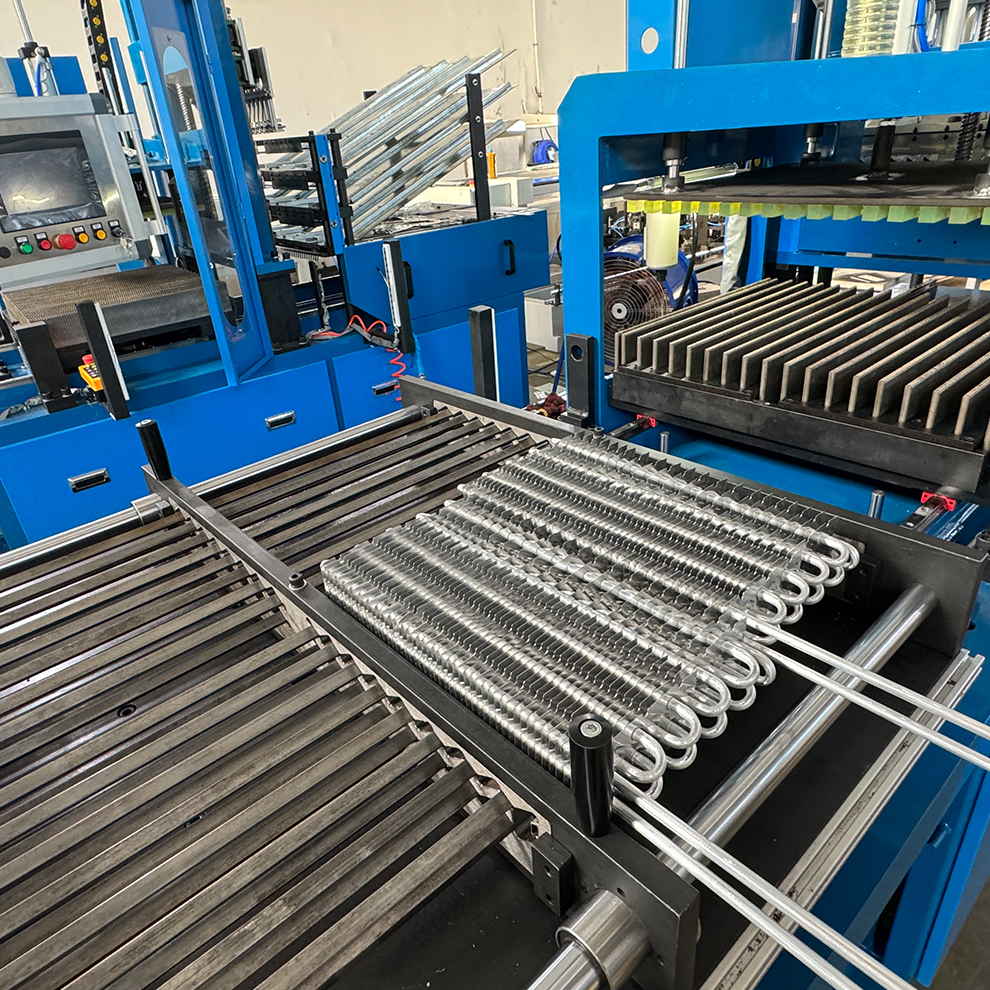

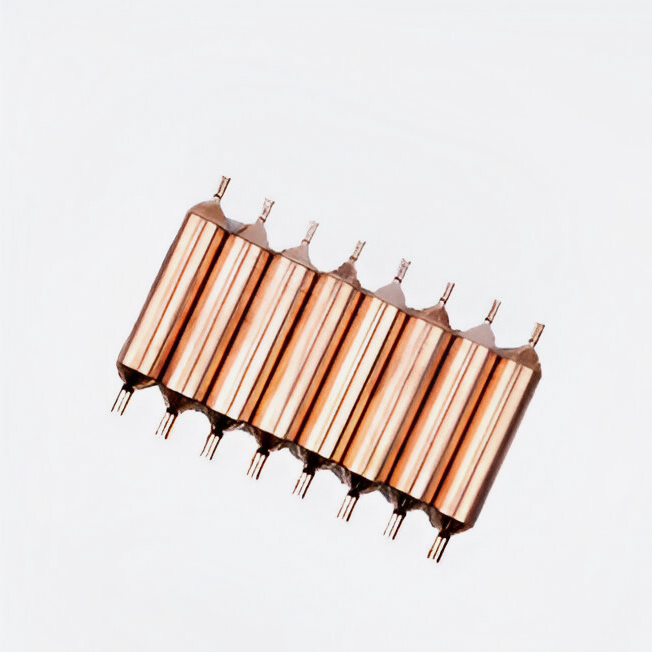

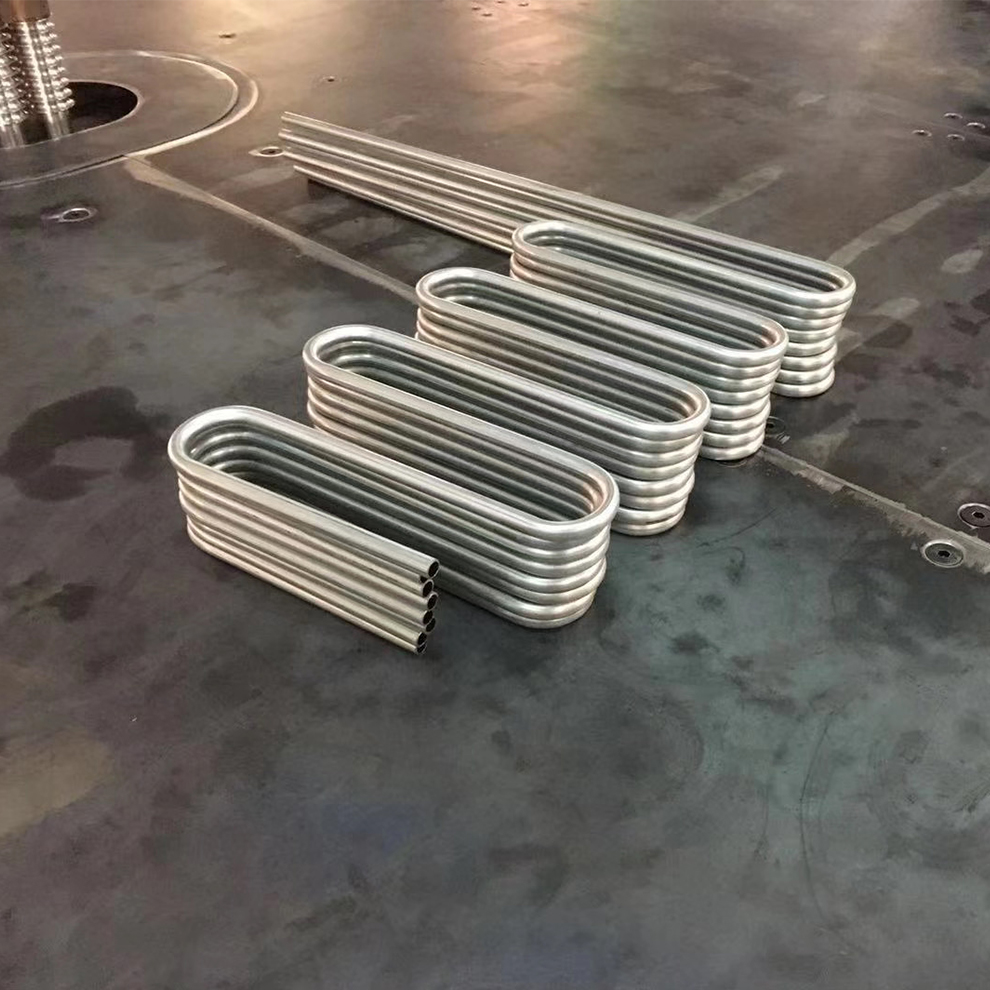

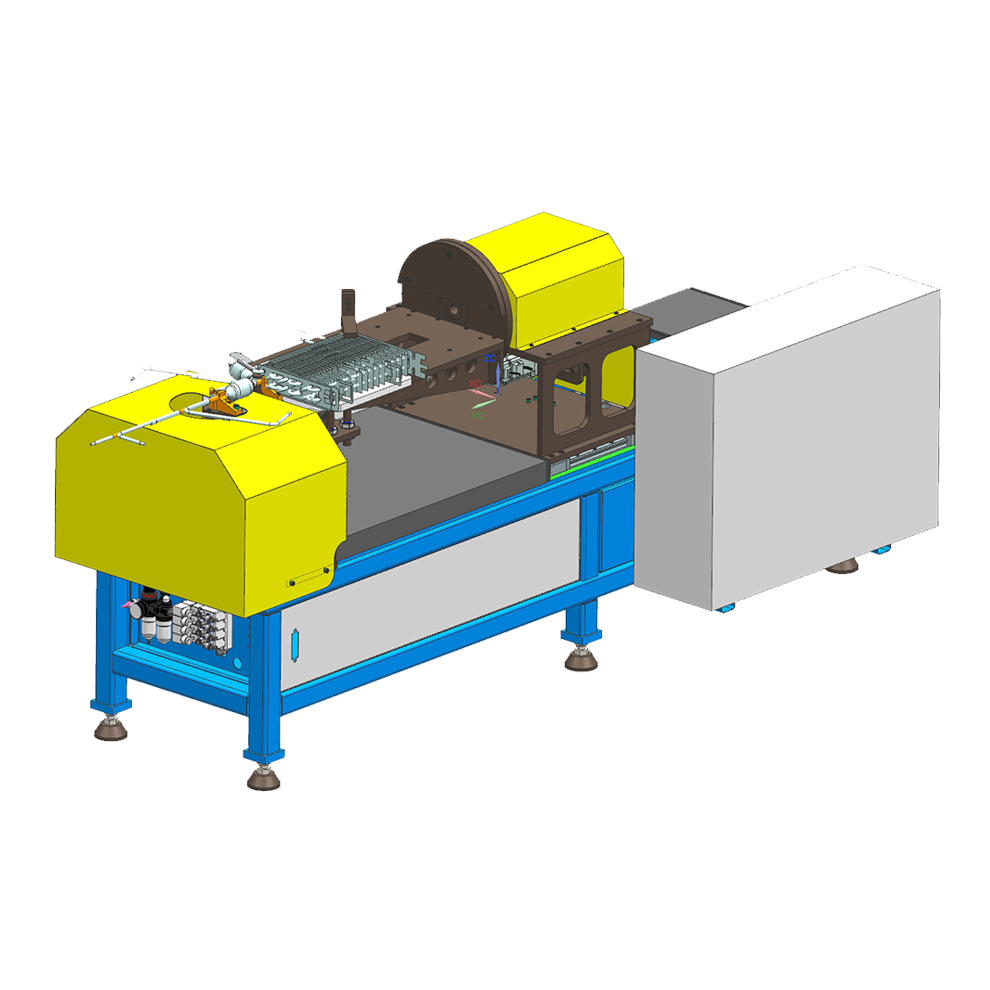

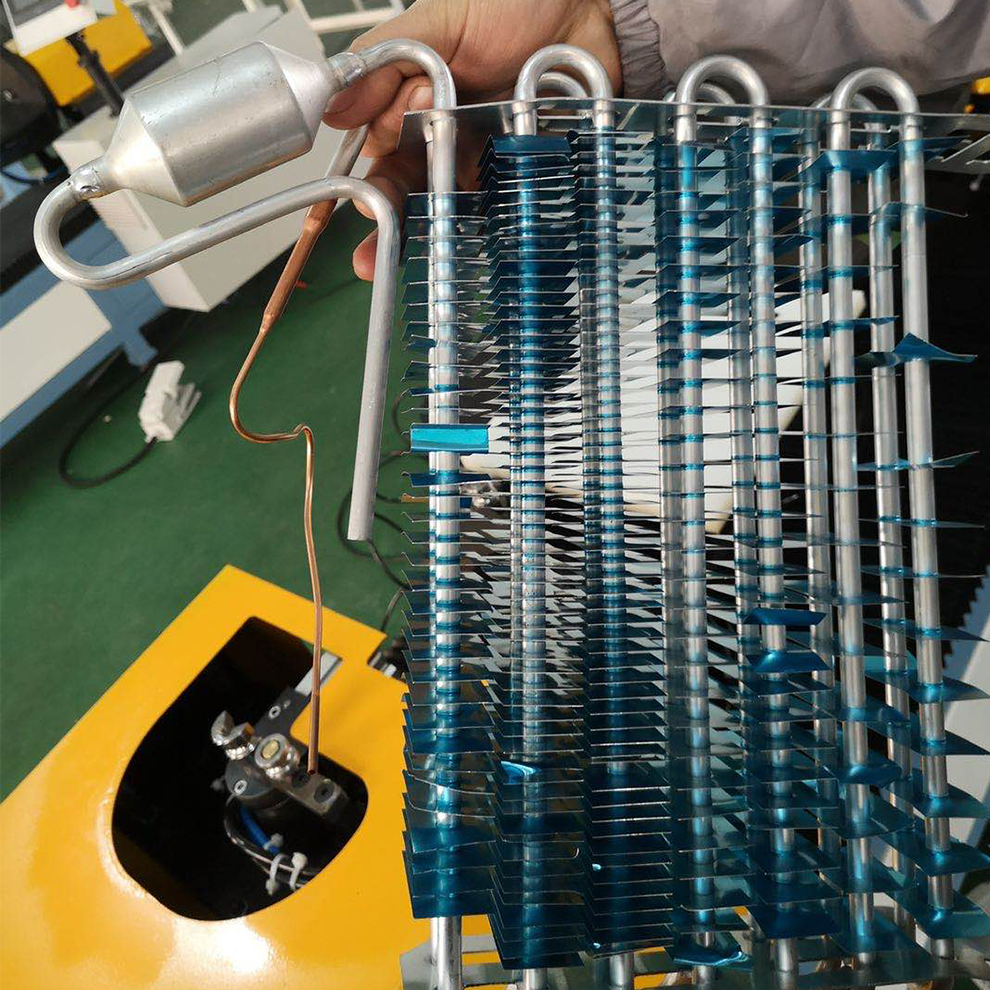

The Automatic Fin Alignment And Expanding Machine is a specialized two-station automatic assembly equipment designed specifically for finned evaporators. Developed by our company, this machine offers easy operation and high work efficiency, making it ideal for mass production. The complete set of equipment consists of three main components: an automatic film arrangement system, an automatic expansion system, and a mold.

At the heart of the device is a PLC programmable controller, which serves as the central control unit. The functionality of the device can be easily adjusted by modifying the program and parameters of the control software, providing flexibility and adaptability to different production requirements.

Parameter

Parameter | Data | |

|---|---|---|

| Dimensions | 4500X2200X1800mm | |

| Weight | 4.2T | |

| Fin coil | Max OD diameter 600mm | |

Parameter | Data | |

|---|---|---|

| Control power | 380V, 50Hz, 3Phae (Customized) | |

| Rated load duration | 12KW | |

Features

End-to-End Automation

Modular Multi-Layer Handling

Precision Expansion Control

Industry-Leading Component Integration

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.