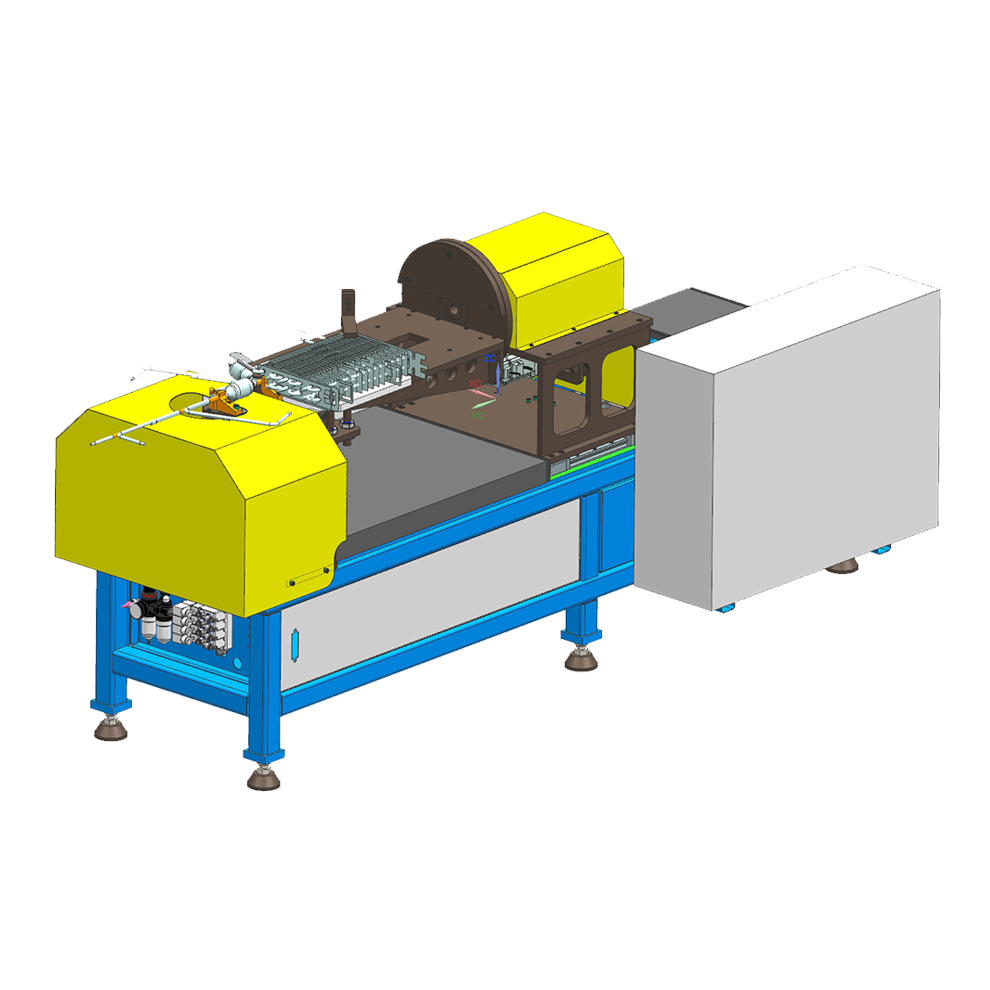

Automatic Tube End Expanding & Shrinking Machine

The Automatic Tube End Expanding & Shrinking Machine is a highly efficient and versatile equipment designed to streamline the process of expanding and shrinking tube ends. It incorporates an automatic feeding device that allows cut pipe codes to be placed in the hopper, enabling the machine to complete the feeding process automatically. The feeding device utilizes a linkage structure to ensure precise and consistent feeding, processing one pipe at a time and eliminating material piling.

Parameter

Parameters | Data | |

|---|---|---|

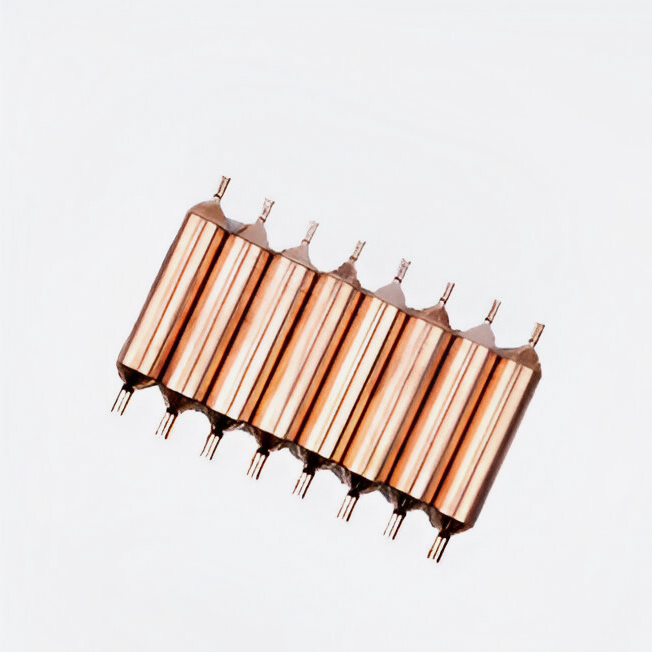

| Tube Material | Copper / Aluminum tube | |

| Tube Diameter | 3-8mm | |

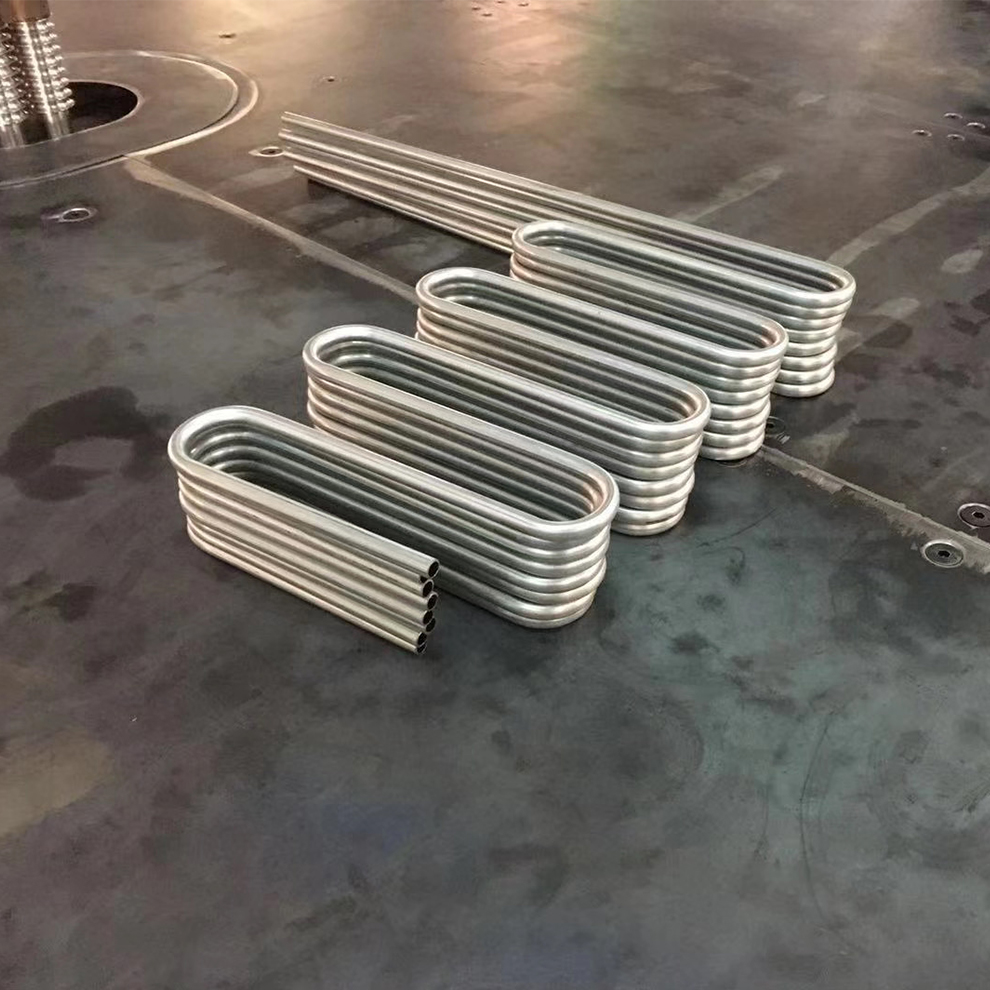

| Tube Length | 70-400mm | |

| Shrinking Length | 30-50mm | |

| Voltage | 380V, 50HZ, 3 phase | |

Parameters | Date | |

|---|---|---|

| Inner Diameter Range | Φ1.9-Φ10.0±0.05mm | |

| Weight | 860kg | |

| Control System | PLC control / HMI | |

| Work Speed | 4-5pcs/min | |

| Power | 2.2kw | |

Features

Intelligent Automation & Material Handling

Precision Forging with Deformation Control

Flexible Configuration & Quiet Operation

Industrial-Grade Durability

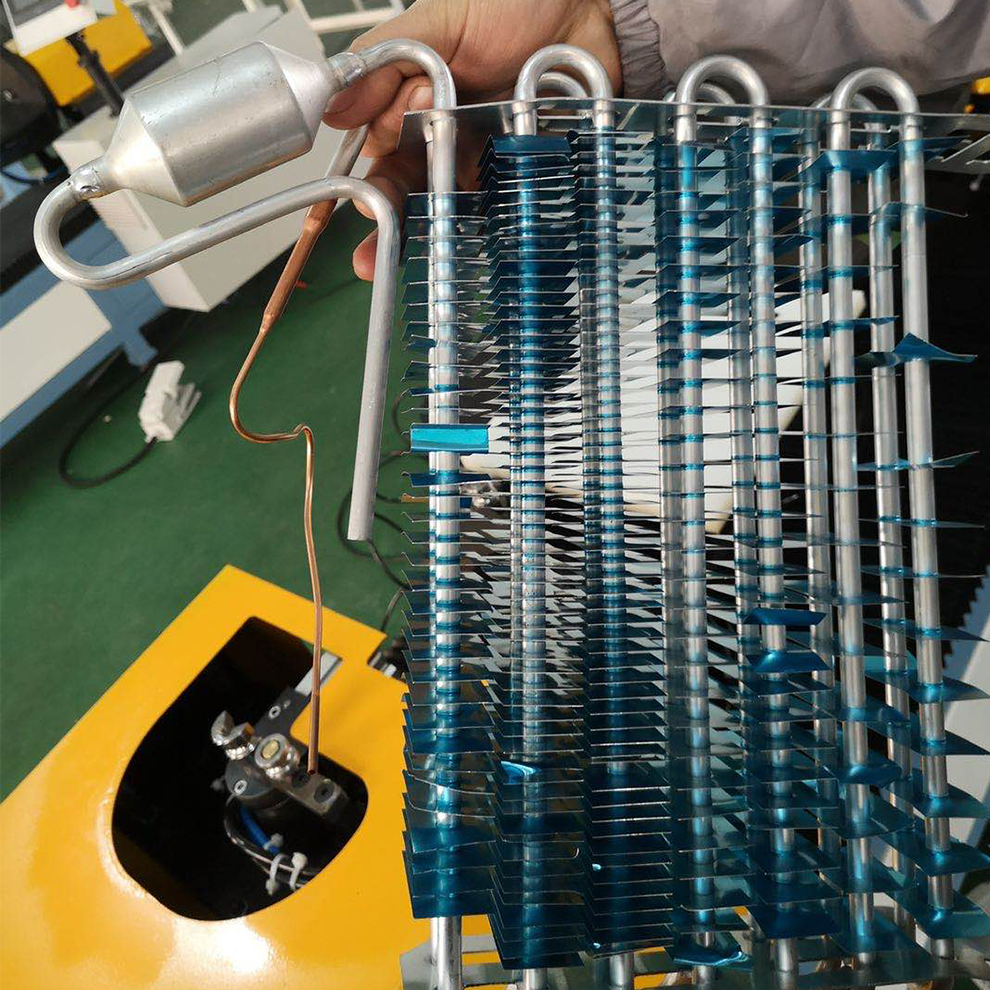

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.