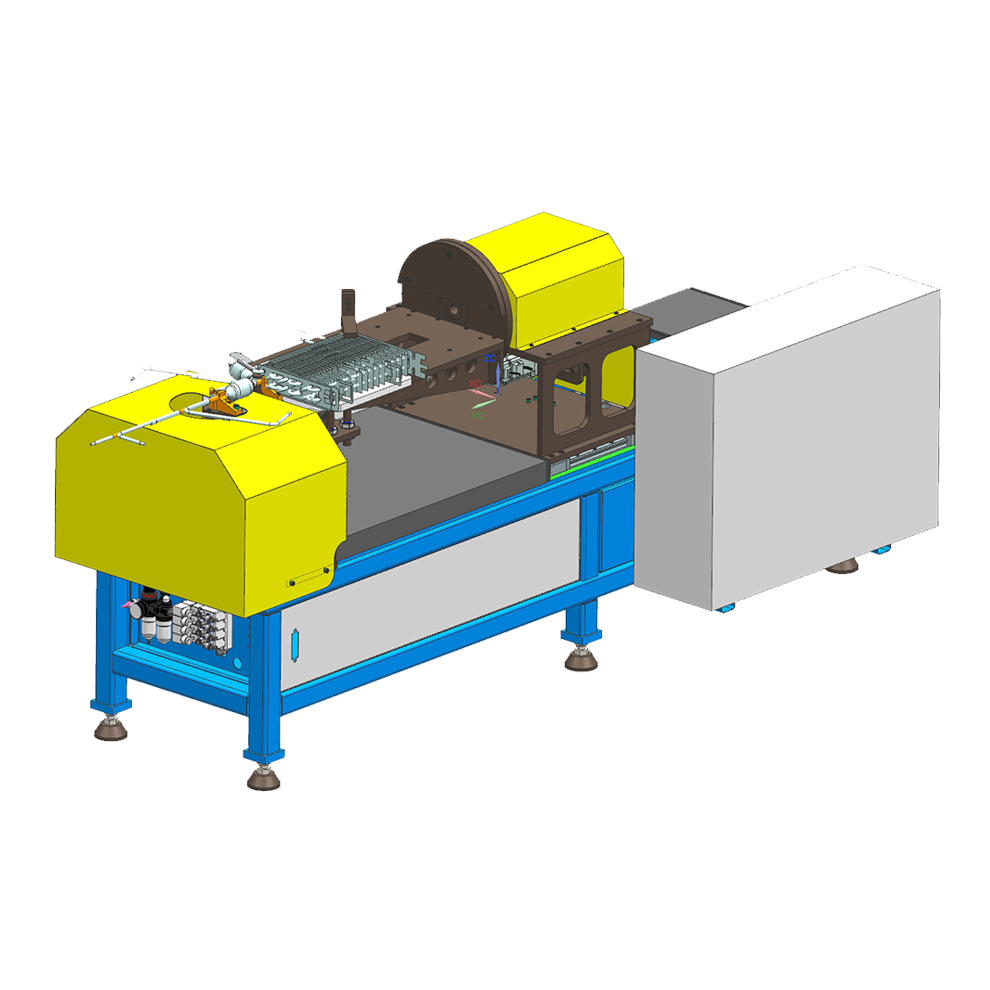

CNC Coil Tube Straightening Cutting Tube End Forming Left&right Bending Machine

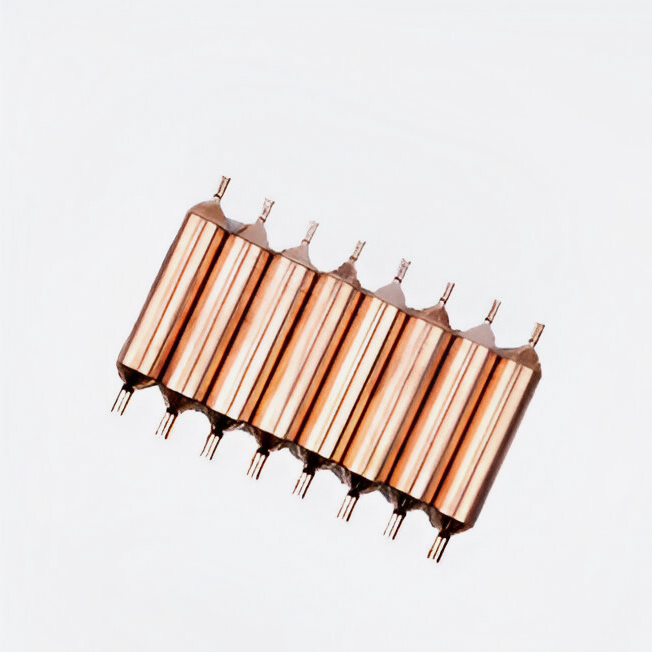

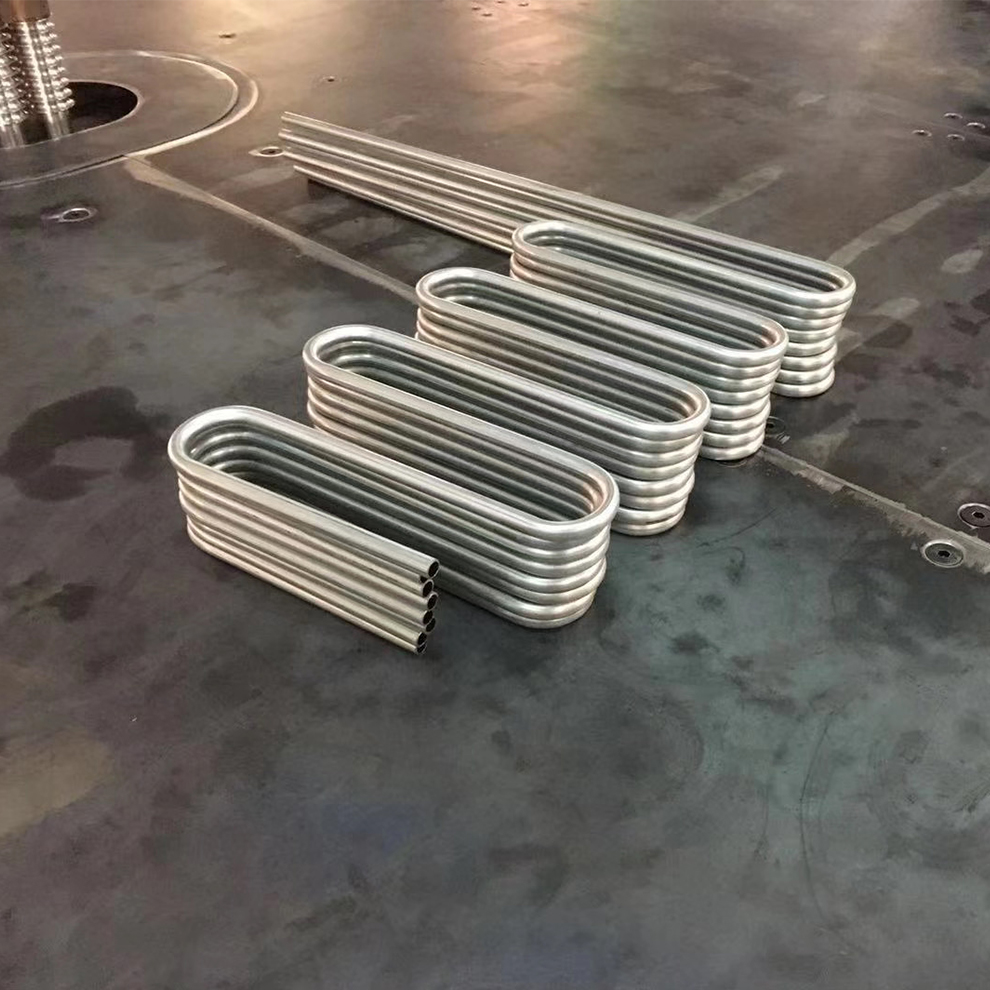

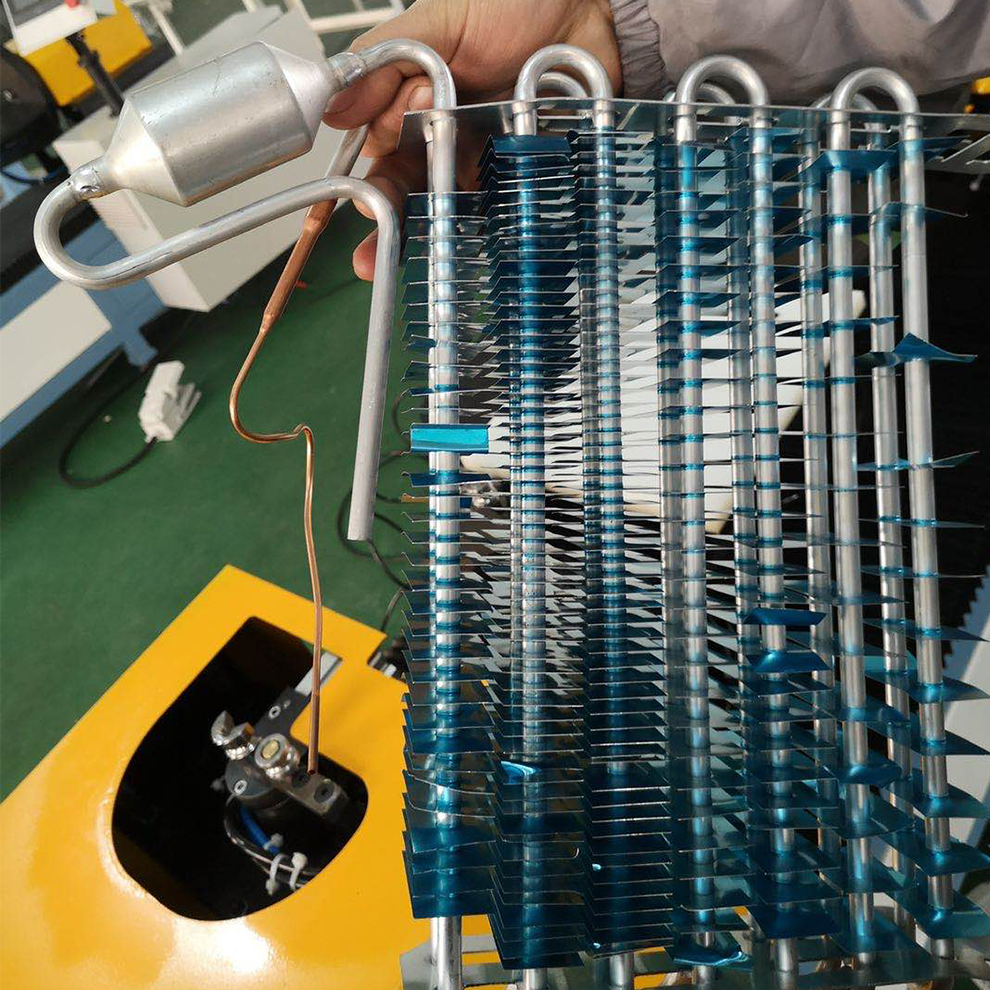

CNC coiled pipe chip-free open pipe end (one drag one, left and right shared) pipe bending all-in-one machine This equipment is used to automatically unwind, straighten, and cut length-free cutting of steel and copper coils. Full-automatic CNC equipment for end forming, three-dimensional CNC automatic bending, and automatic feeding by servo manipulators. It is mainly used for automatic chipless opening of copper, aluminum, and steel coil pipe fittings for air conditioners, water heaters, aircraft, automobiles, etc. ) Multi-station pipe end forming (or dot), high-end automated combined equipment for automatic bending forming left and right sharing.

Parameter

Item | Brand | |

|---|---|---|

| Main machine | Welding (Eliminate stress processing ) | |

| Auto decoiler | Inner pull model | |

| CNC system | ICM(With SD import, view function, can connect with MES system) | |

| Servo system | Mitsubishi | |

| Switch | Schneider | |

Item | Brand | |

|---|---|---|

| Proximity switch | Otonix. | |

| Low-voltage appliances | Schneider, Izumi, Otonix. | |

| Pneumatic components (cylinder) | AirTAC | |

| Reducer | VGM/TOMOGAWA | |

Features

Multi-Axis Servo Precision

Intelligent Process Automation

Military-Grade Durability

Zero-Deflectiom Tooling

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.