Condenser & Evaporator Flame Brazing Welding Machine Line

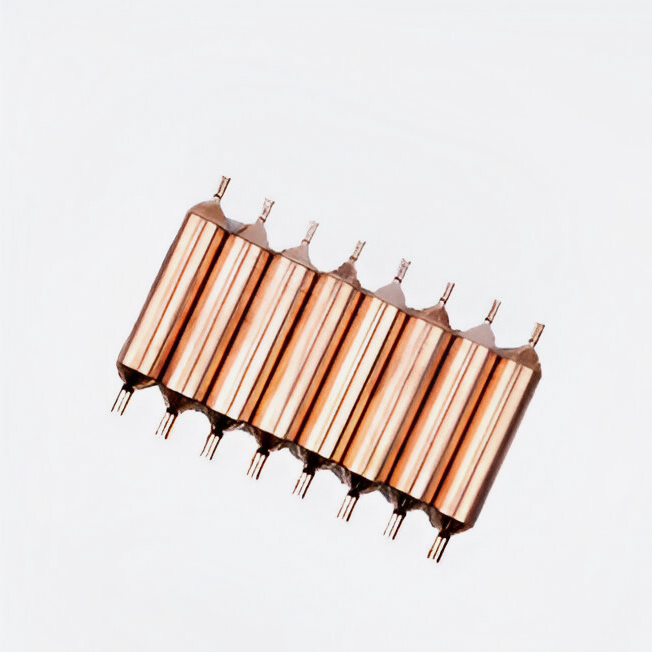

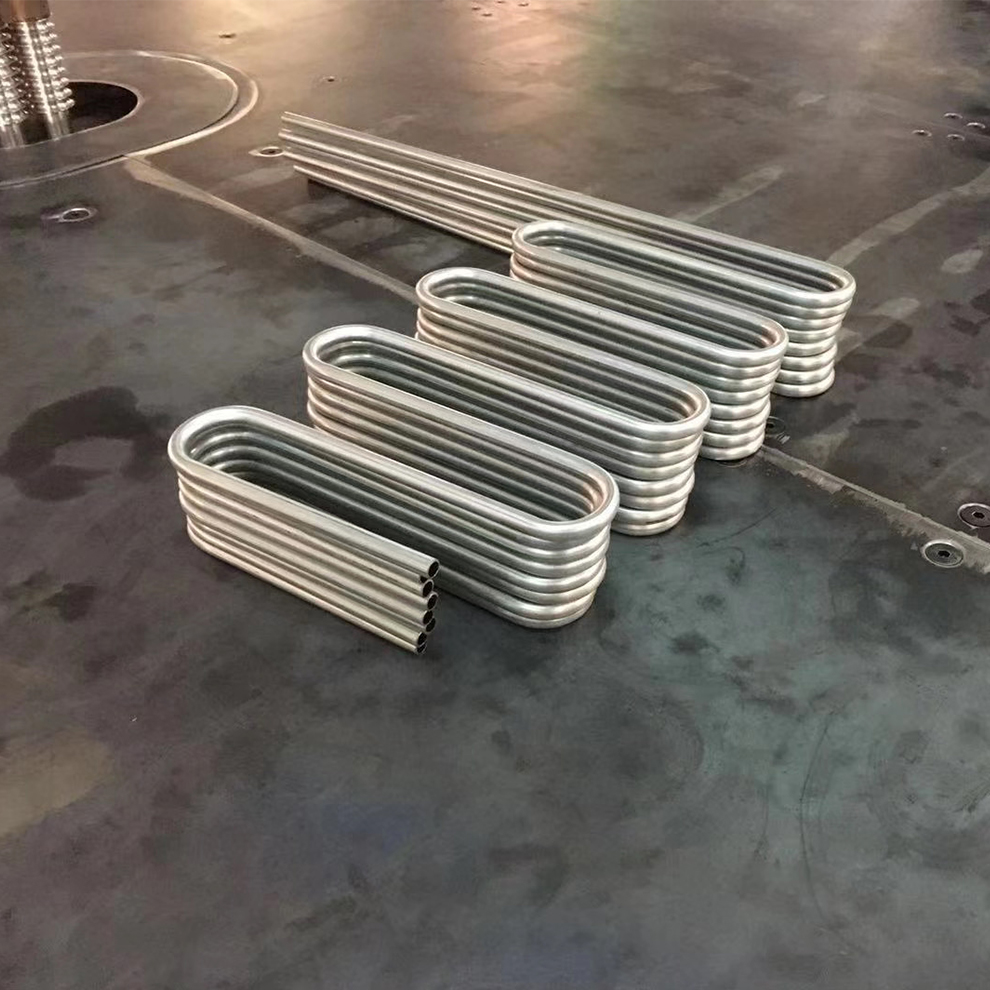

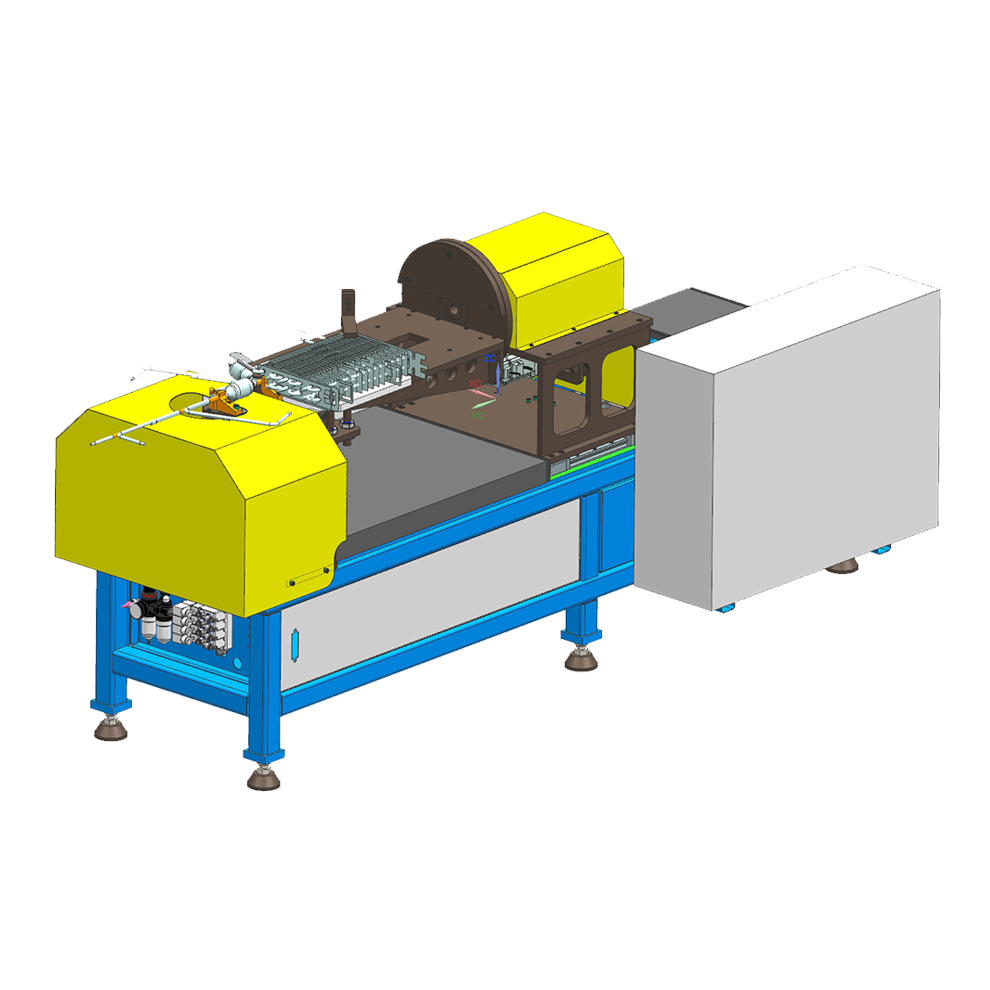

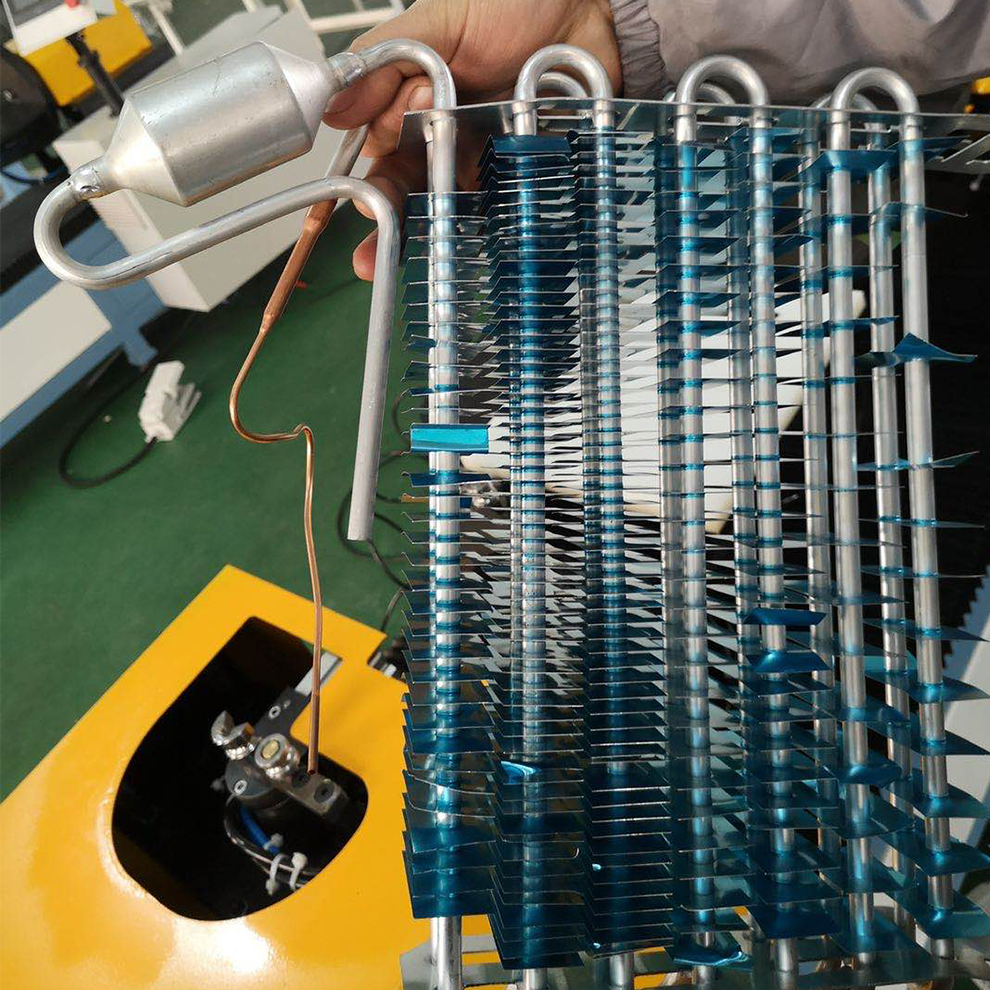

The welding machine is a linear structure consisting of frame, drive, transmission line and fire exhaust combustion mechanism. It is suitable for continuous heating of two copper tubes, copper elbows and welding rings, so that the welding rings can melt and evenly fill the gap between the copper tubes and the copper tubes, thus realizing automatic welding of the two devices. Gas, oxygen and nitrogen can be accurately controlled by FLOTRON DF11K / MFC, which ensures stable welding temperature and reliable welding quality.

Parameter

Name | Data | |

|---|---|---|

| Machine length | 10M(standard model can be increased due to production) | |

| Input platform | 4M | |

| Welding chamber | 1850*1400*3200mm(exclude exhaust hood) | |

| Output platform | 4.25M | |

| Transport platform height | 400mm | |

| Delivery motor speed | 0~3000mm(variable frequency control speed) | |

Name | Data | |

|---|---|---|

| Feeder speed control flame array up/down control | 380V, 50Hz, 3Phae (Customized) | |

| Rise and fall speed | 250mm/min | |

| LPG gas(coal gas) | 1.5 Kg/ cm2 | |

| Pipe-line gas | 1 Kg/ cm2 | |

| Compressed air | 4~6 Kg/ cm2 | |

| Support rod seat | 38.1 mm round tube | |

| Dimension | 650X550X1000mm | |

Features

Precision Flame & Atmosphere Management

Multi-Row Synchronized Processing

Fail-Safe Thermal Governance

Scalable Line Architecture

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.