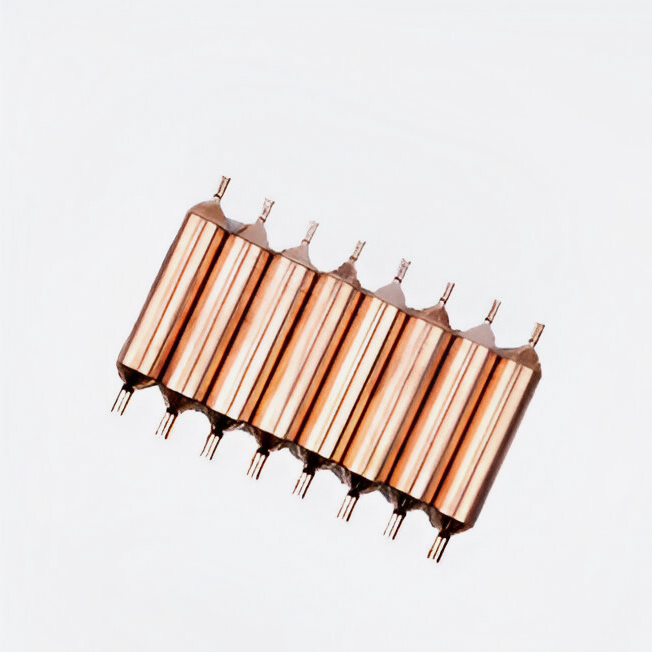

Copper Tube Spinning Machine

The principle of the spinning machine is that when the workpiece rotates at a high speed, the workpiece is pressed by a certain path through a strong external force, and the material is repeatedly pressed by the roller to make it from point to line, and the line to the surface eventually causes the workpiece to be thermally deformed. The shape you need. Depending on the required pressing force, the small spinning machine can drive the screw to generate pressure through the servo motor. Some large-scale powerful spinning machines need to be squeezed by hydraulic means.

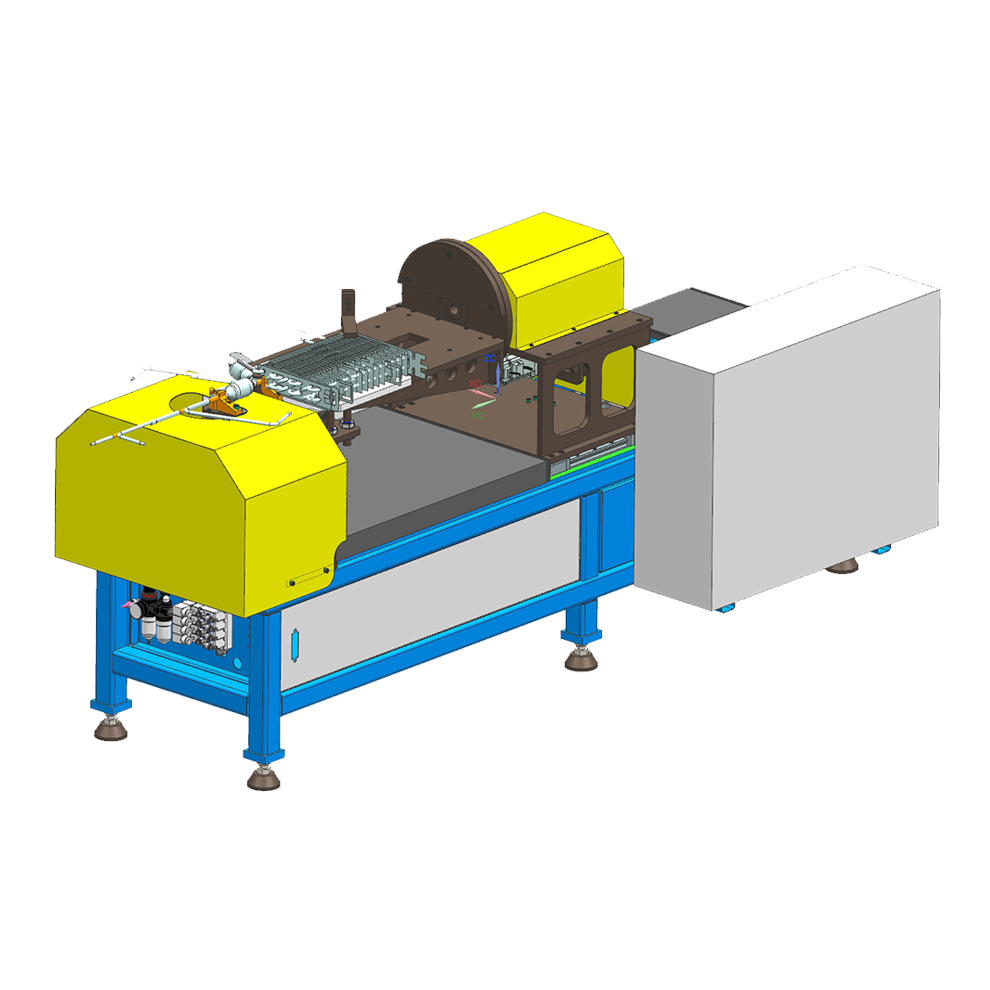

Parameter

Parameters | Data | |

|---|---|---|

| Tube diameter range | 5-32mm | |

| Working thickness | 0.2-2mm | |

| Tube length | 86≤L≤350mm | |

| Power | 380V(AC)±10%,50HZ | |

| Air pressure | 0.5±0.1MPa | |

| Control system | CNC system | |

| X axis | 200mm | |

| X axis precision | ±0.05 | |

| X Axis speed | 300mm/S | |

| Y axis stroke | 100mm | |

| Y axis precision | ±0.05 | |

| Y axis speed | 150mm/S | |

Parameters | Date | |

|---|---|---|

| Material Moving | Automatic /Manual option | |

| Working stations | 1 station | |

| Working way | Cold spinning | |

| Operation | Auto/manual/Jog | |

| Clamp way | Hydraulic air core rotary cylinder | |

| Hydraulic press power | 5MPa | |

| Capacity | 30s/pc | |

| Motor power | 3Kw | |

| Hydraulic power | 3KW (Total 6Kw) | |

| Dimension | 1800*900*1500(mm) | |

| Weight | 1ton | |

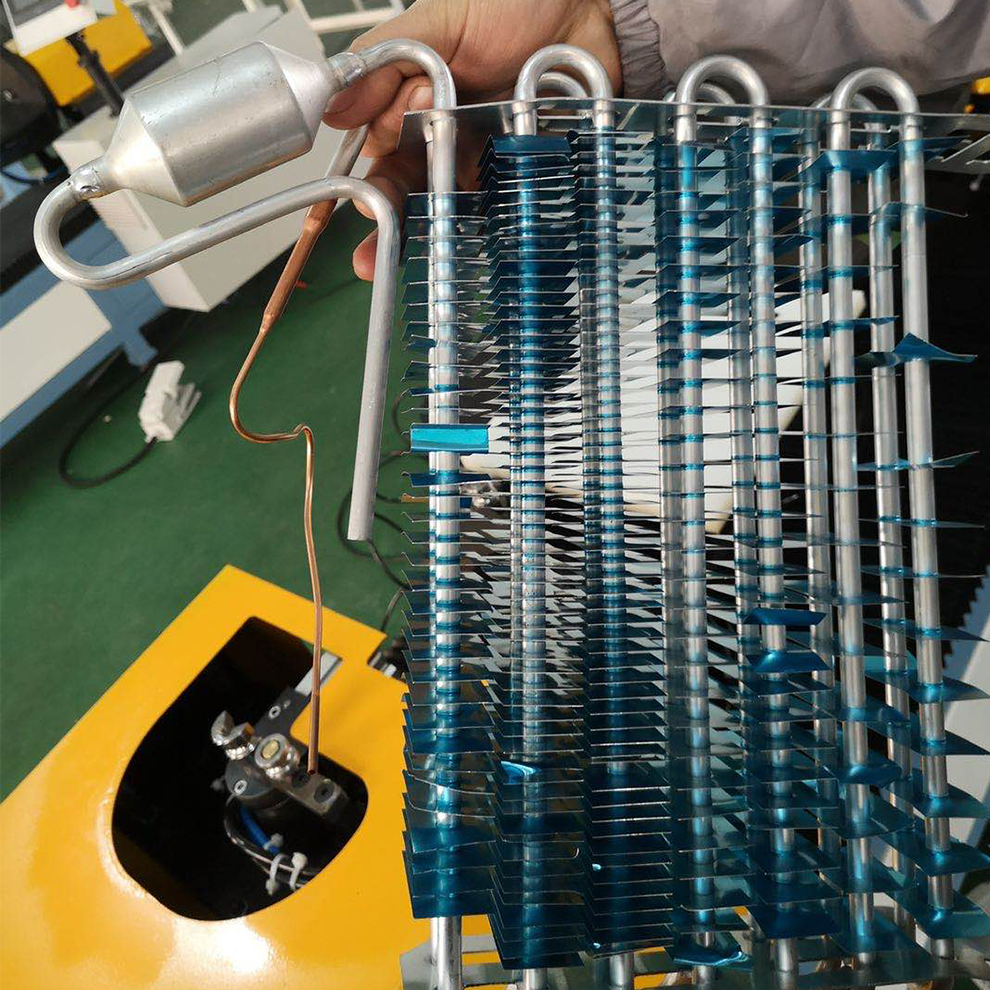

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

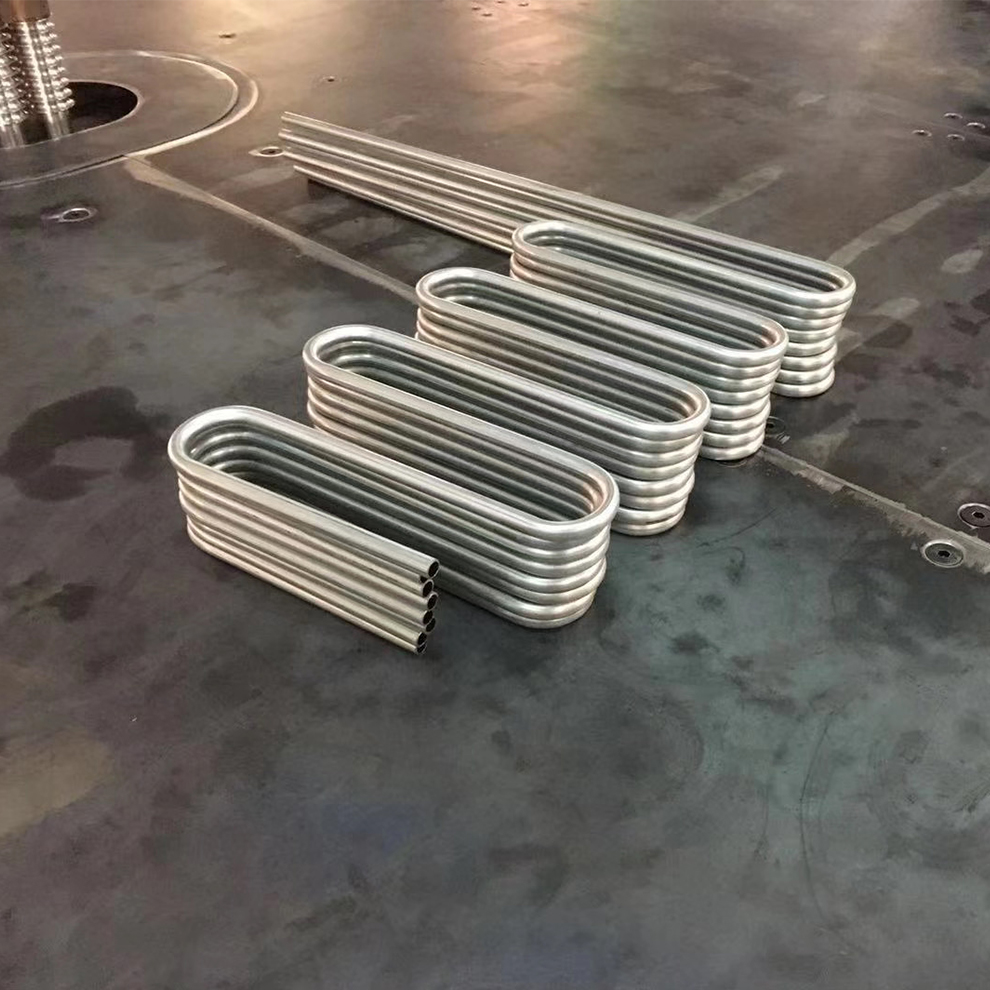

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.