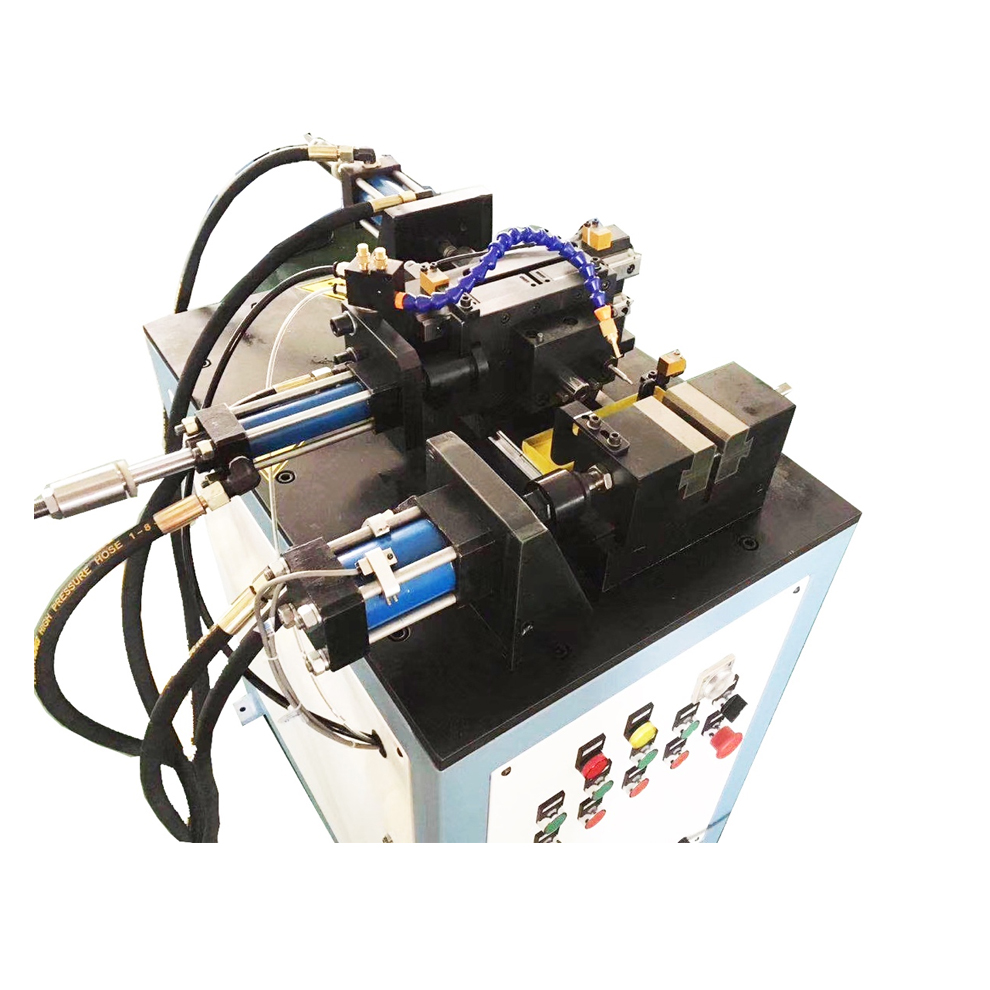

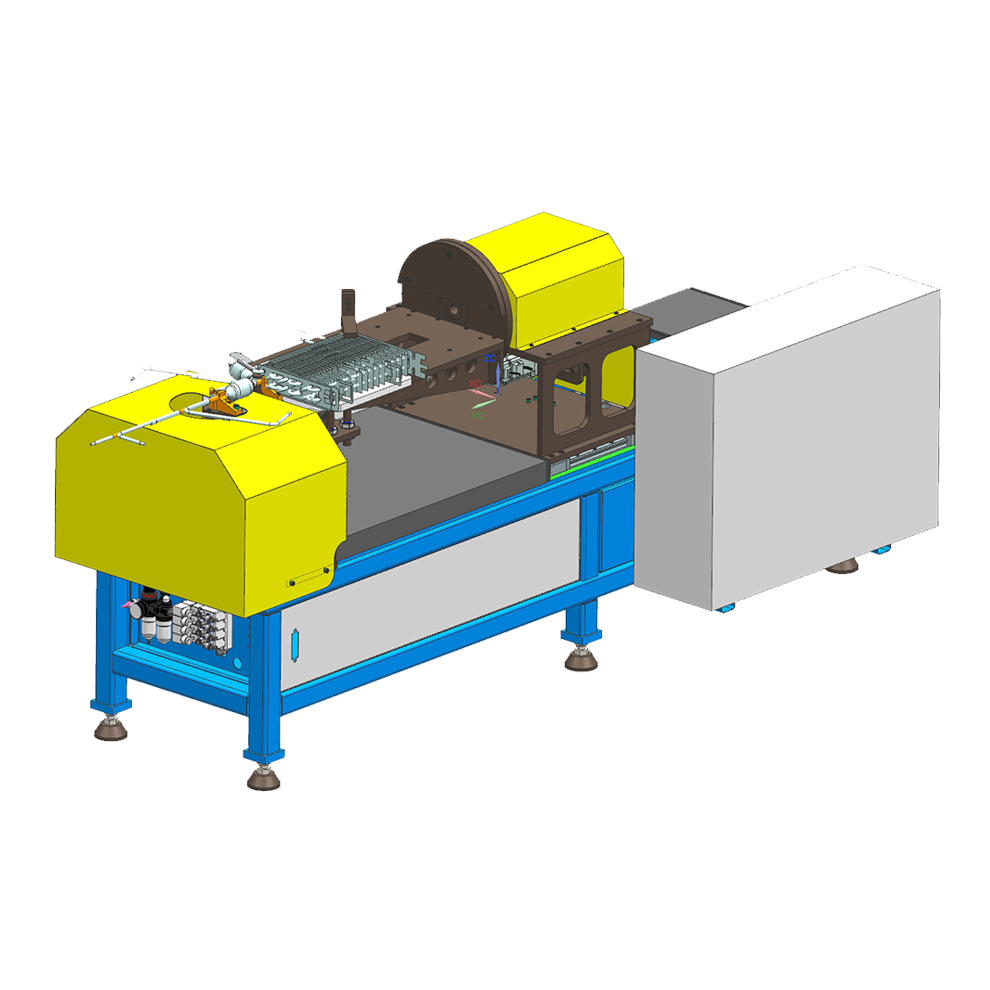

Dual Station Tube End Forming Machine

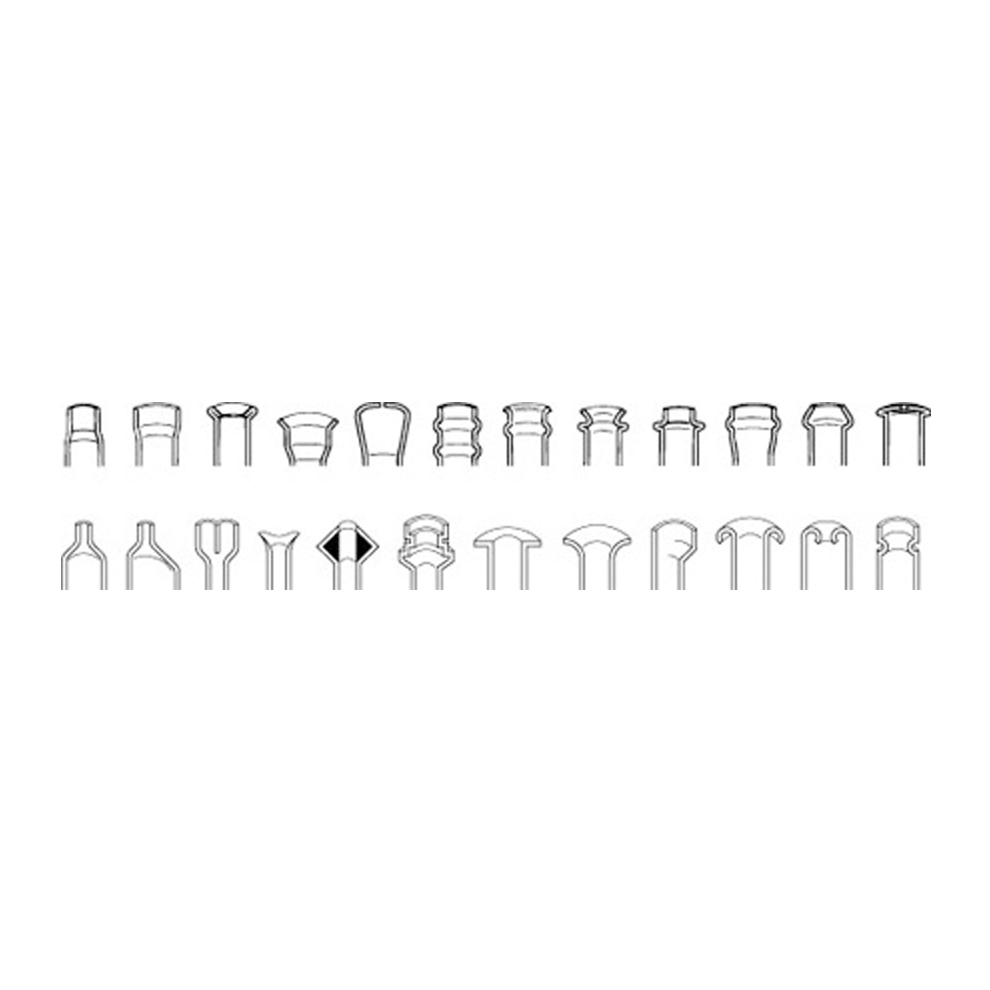

The manual tube end forming machine is designed to shrink tube end part by rotary swaging process. With upgraded four-diedesign, thefinished tube presents high quality, and working noise keeps less than before. Forming by rotary swaging process for welding process in next step.Four-die design for less noise and better quality product.Special designed forming die ensure welding quality with less waste in next step.Casted forming head housing ensure stable performance and long-life use.Core-bar design to ensure the inner diameter during process.

Parameter

Parameters | Data | |

|---|---|---|

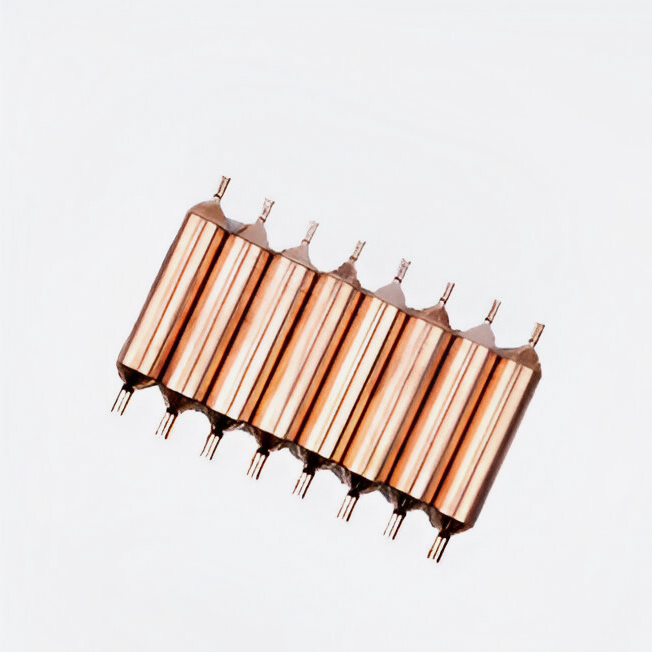

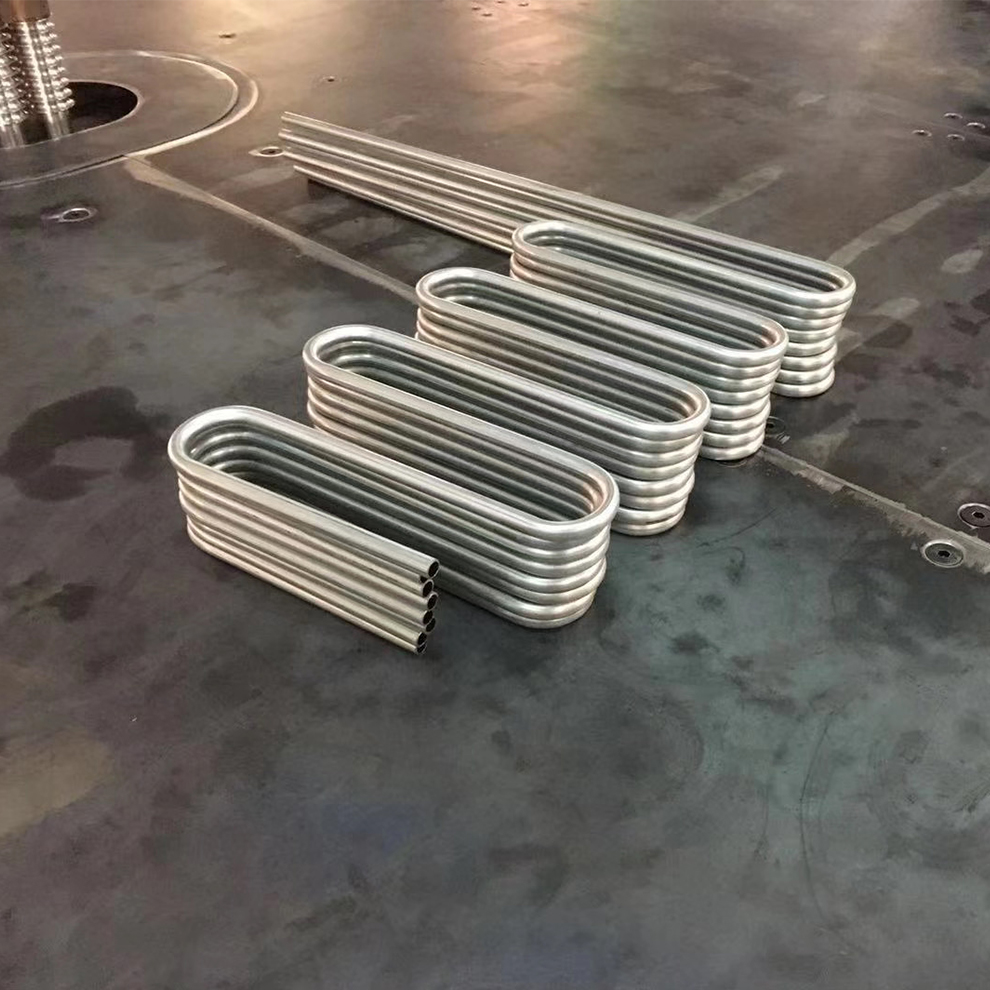

| Tube materials | Copper / Aluminum / Bundy tube | |

| Suitable diameter | 4-20mm | |

| Forming Length | 5-50mm (Customized) | |

| Work Speed | 10-15 pcs/min | |

| Inner Diameter range | Φ1.9-Φ10.0±0.05mm | |

Parameters | Date | |

|---|---|---|

| Tube Feeding | Manual | |

| Motor Power | 1.5 KW | |

| Electric System | 380V, 50Hz, 3Phae (Customized) | |

| Dimension | 800 x 600 x 1100 mm | |

| Weight | 450 KG | |

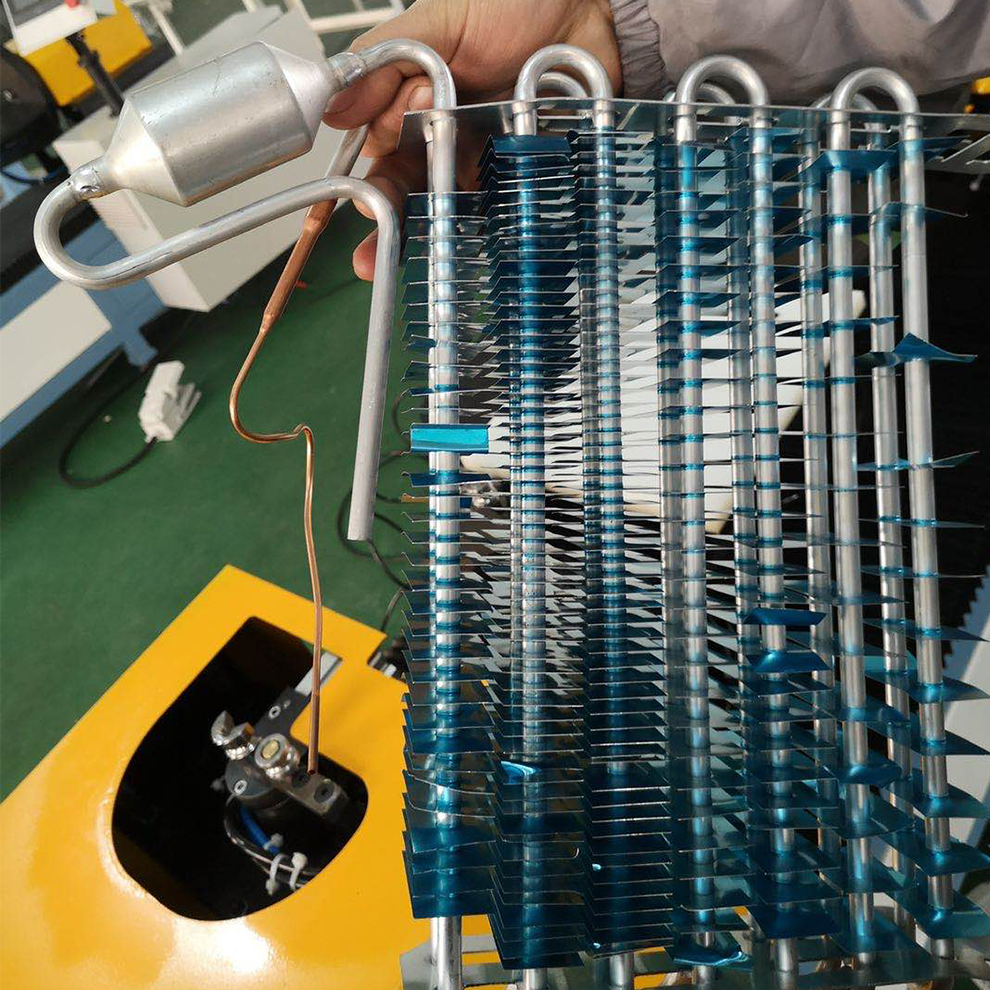

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.