Full Automatic Fin Type Evaporator Serpentine Tube Bender

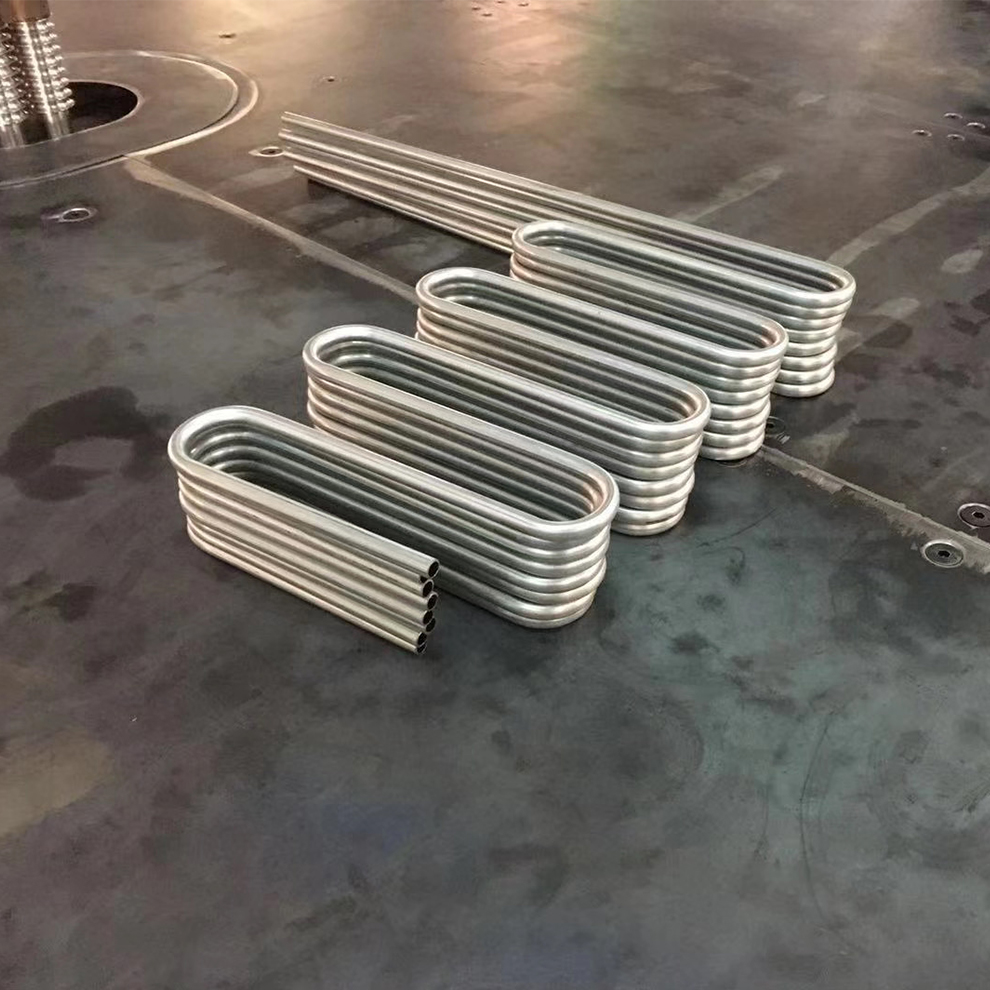

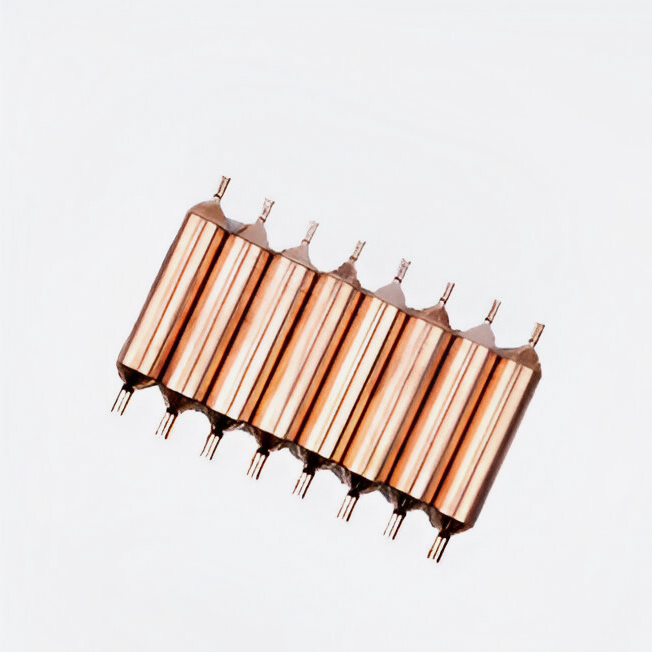

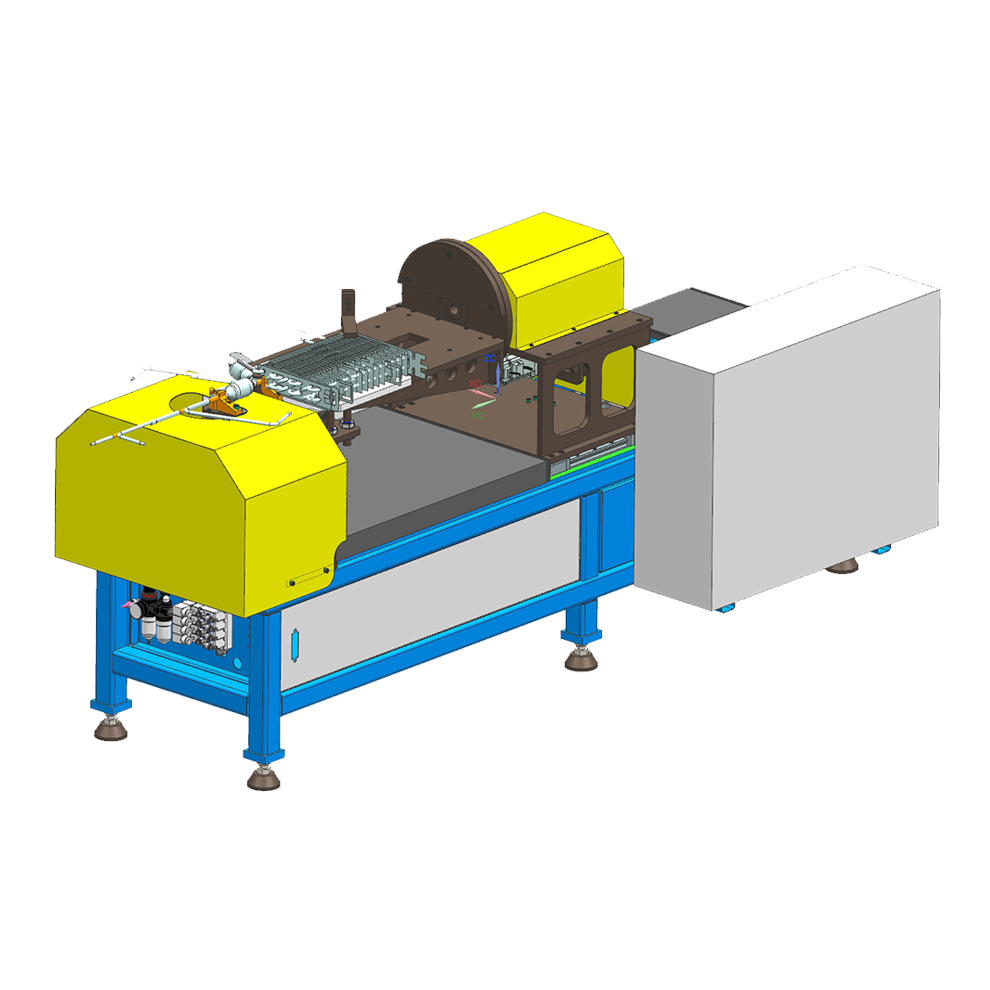

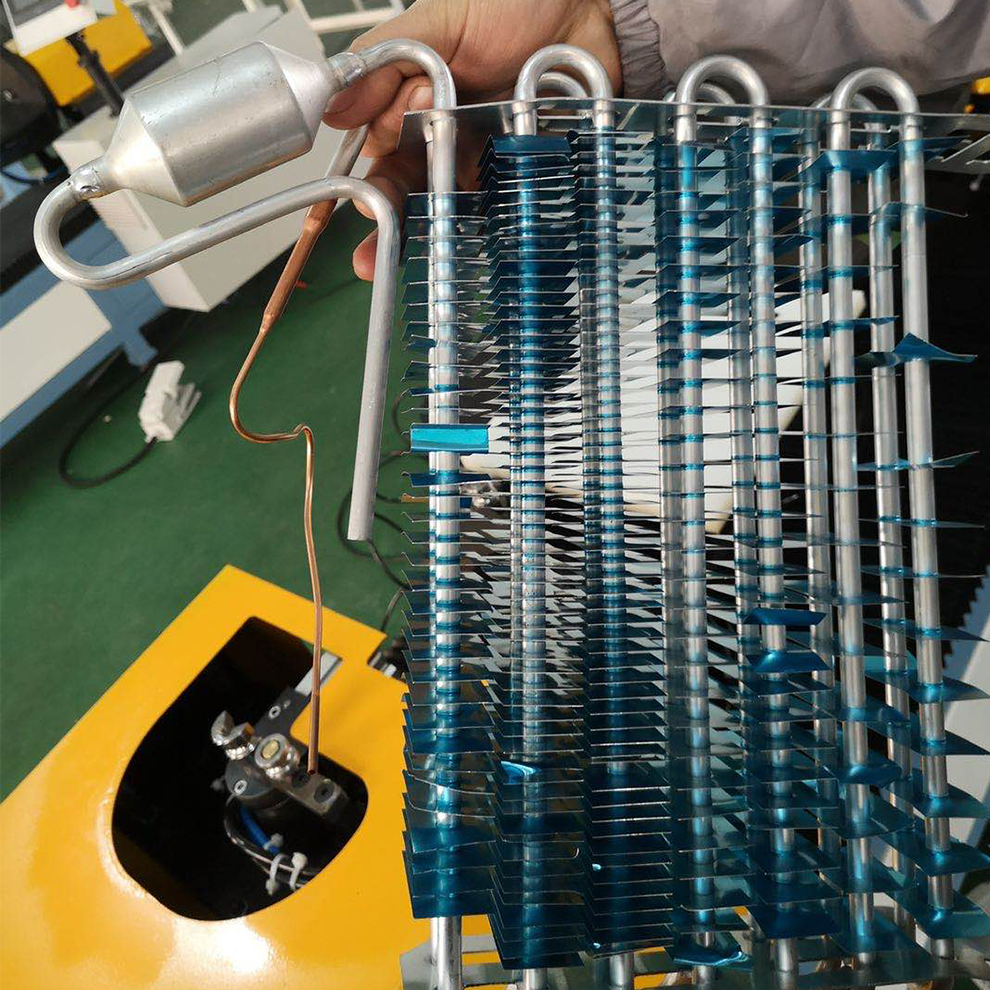

The full automatic fin evaporator serpentine tube bender delivers complete in-line bending automation for mass production of aluminum tubes used in HVAC heat exchangers and air conditioning evaporator coils. It integrates the entire end-to-end process from decoiling, straightening, cutting, bending, and recoiling finished serpentine tubing with minimal manual intervention.

Parameter

Part | Brand | Remark | |

|---|---|---|---|

| Main Frame | Home made | Welding | |

| Painting | Home made | Powder Coating / customized color | |

| PLC controller | Mitsubishi | CE / FC / CCC | |

Part | Brand | Remark | |

|---|---|---|---|

| Contactor & Switches | Schneider | CE / FC | |

| Ball Screw | Hiwin | - | |

| Servo Driven System | Mitsubishi | CE/FC/CCC | |

| Motor | WN | CE/CCC | |

Features

Multi-Tube Synchronized Bending

Ultra-Tight Bend Capability

All-in-One Automation

Heavy-Duty Frame & Precision Drives

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.