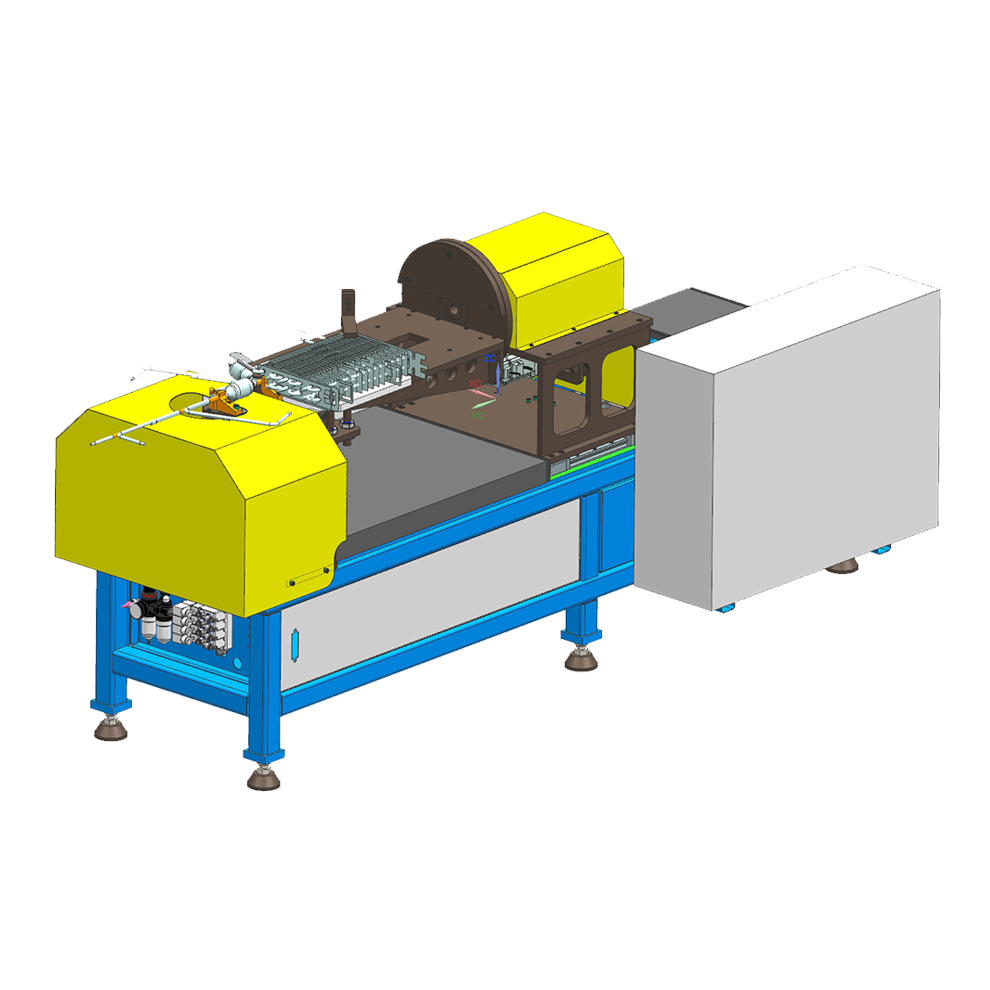

Full Automatic Serpentine Bender

The bender features an all-welded steel frame and base for stability. The modular construction allows easy access and maintenance. Industrial-grade coating on all parts enhances durability. Critical components are sourced from reputable brands to ensure precision capabilities.

Parameter

Parameter | Data | |

|---|---|---|

| Tube Material | Stainless steeltube | |

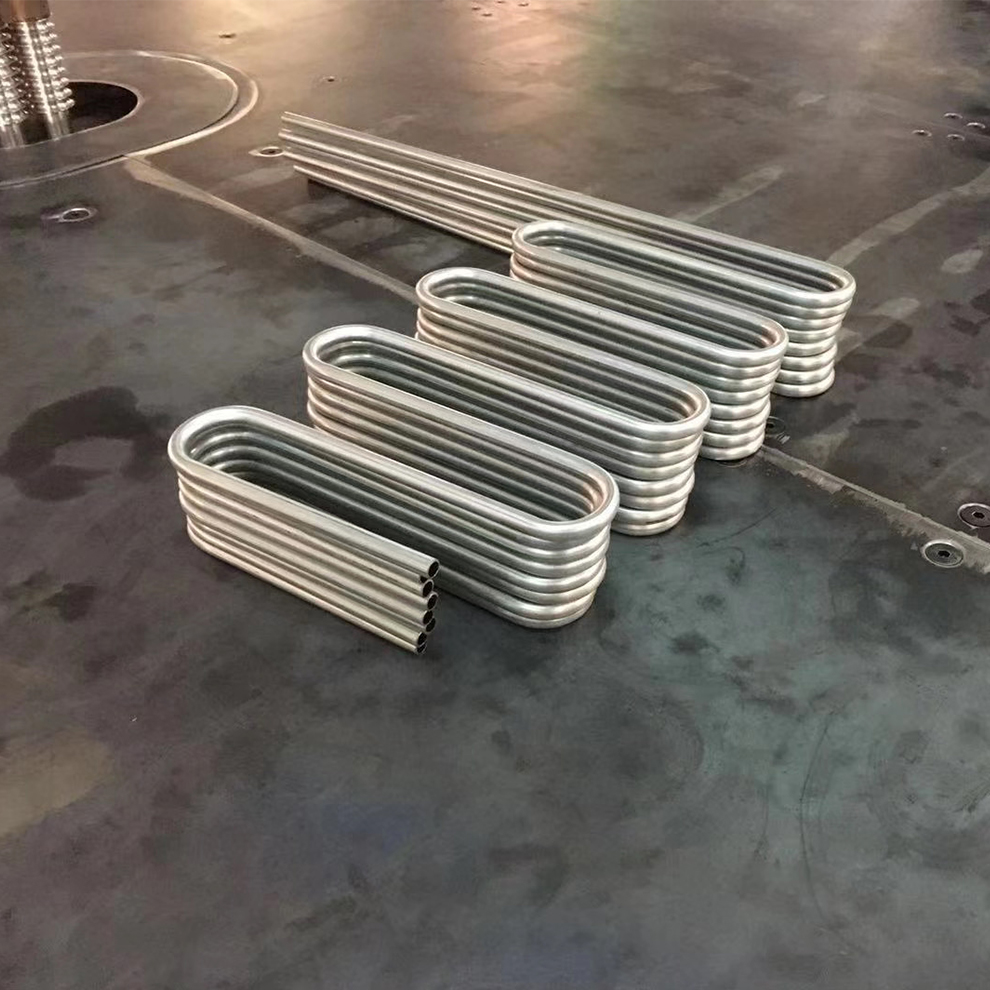

| Tube Diameter | Φ9-20mm | |

| Tube Wall Thickness | 0.3-1.2mm | |

| Bending Capacity | Single tube | |

| Bending Angle | 1~180 degree | |

| Bending Radius | R35~R50 | |

| Bending Times | Up to 110 times/cycle | |

| Feeding length | 0-600mm/time, max. 3 times | |

Parameter | Data | |

|---|---|---|

| Rotary Table Size | Φ2000mm | |

| Control System | PLC control / Touch Screen | |

| Air Pressure | 0.5-0.6MPa | |

| Motor Power | 15KW | |

| Electric System | 380V, 50Hz, 3Phae (Customized) | |

| Dimension | 2200 x 1000 x 1580 mm (Excluded Table) | |

| Weight | About 1300 KG | |

Features

Smart Servo-Electric Automation

Three-Part Precision Clamping

360° Rotary Positioning

Patented Anti-Damage Tooling

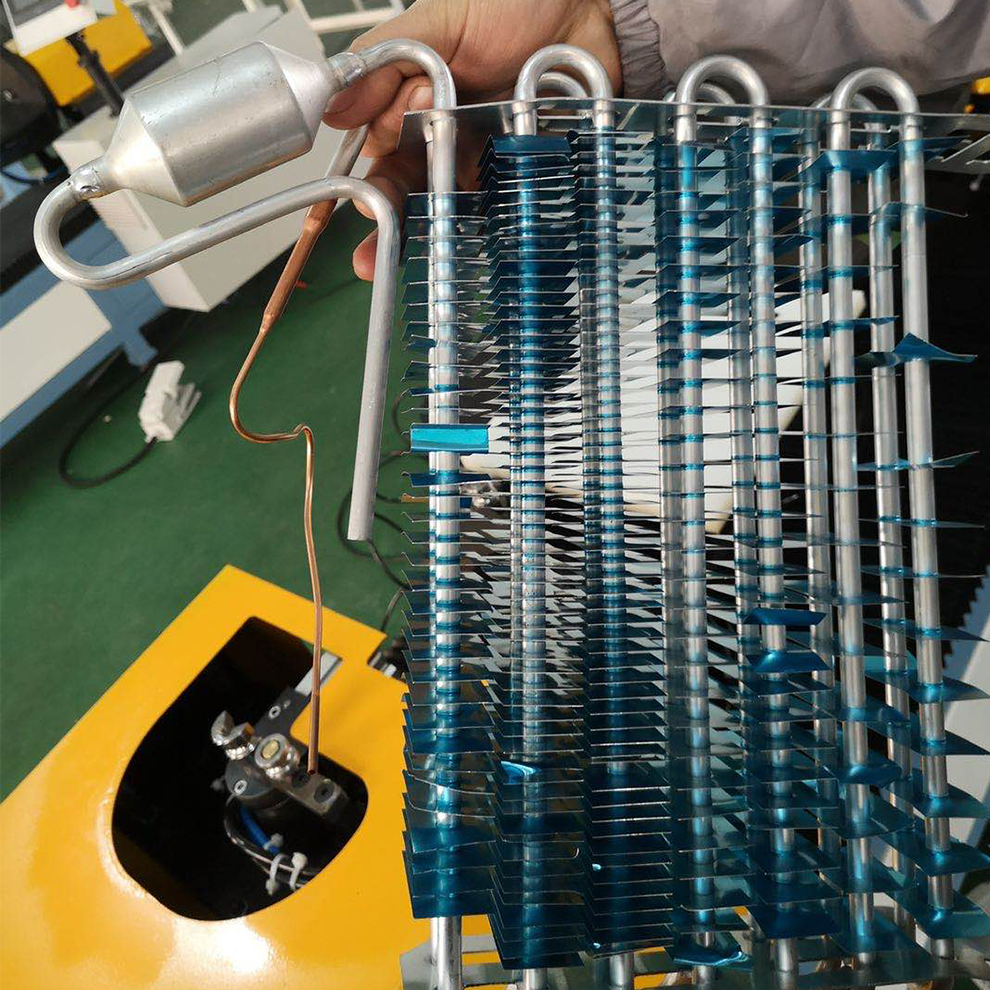

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

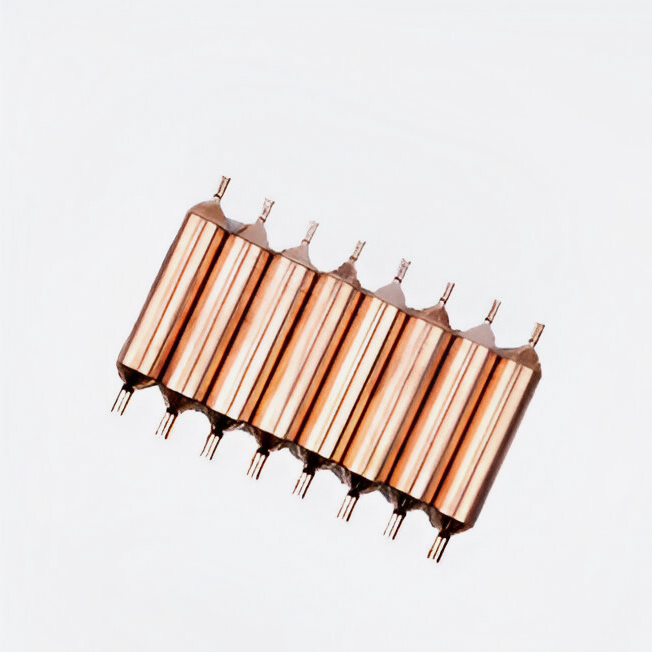

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.