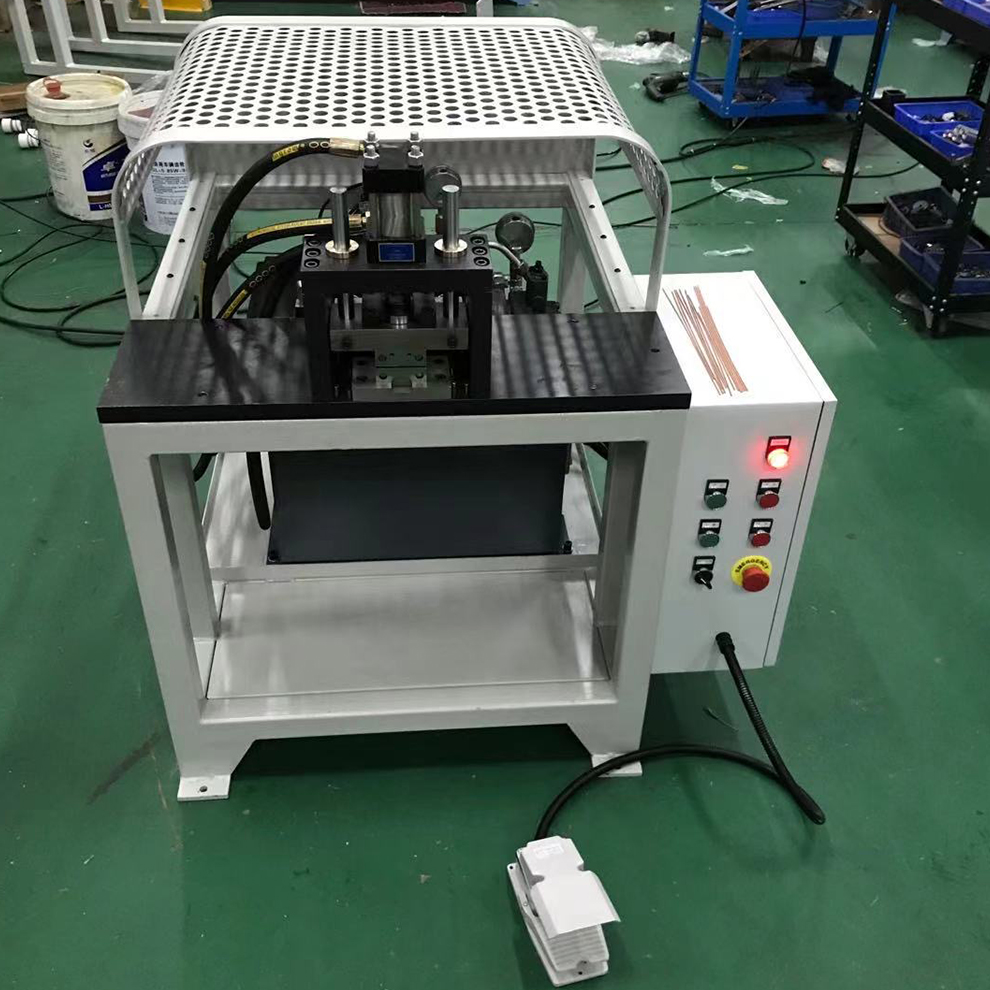

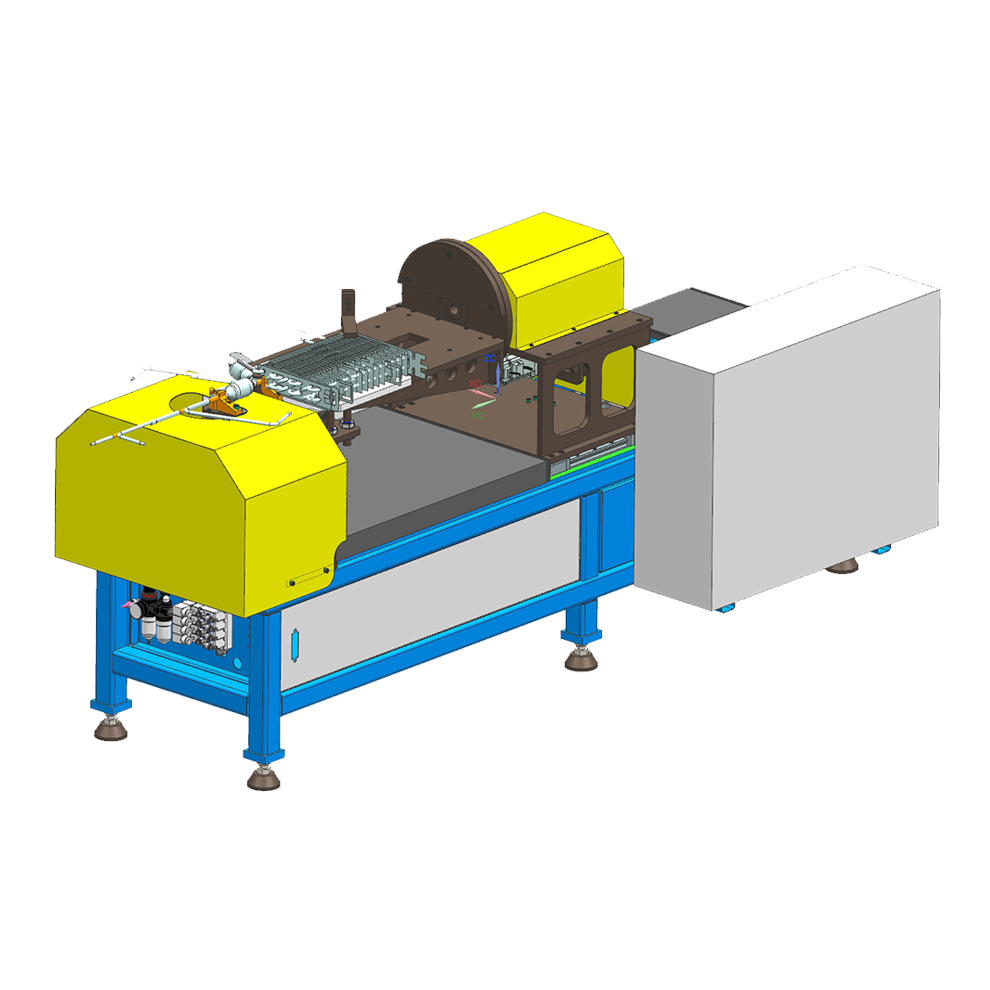

Hydraulic Copper Capillary Tube Bulging Machine

The equipment is composed of steel structure, clamping mechanism, forming mechanism, air cylinder, control circuit and molds.

220v power supply, PLC programmable controller or continuous electrical control, automatic pedal operation, simple operation, stable and reliable, and convenient maintenance

Manual operation, manual loading of the tube, placing the tube into the mold and positioning, foot switch, automatic action, manual removal of the tube.

Parameter

Item | Parameters | |

|---|---|---|

| Model | DB-10M | |

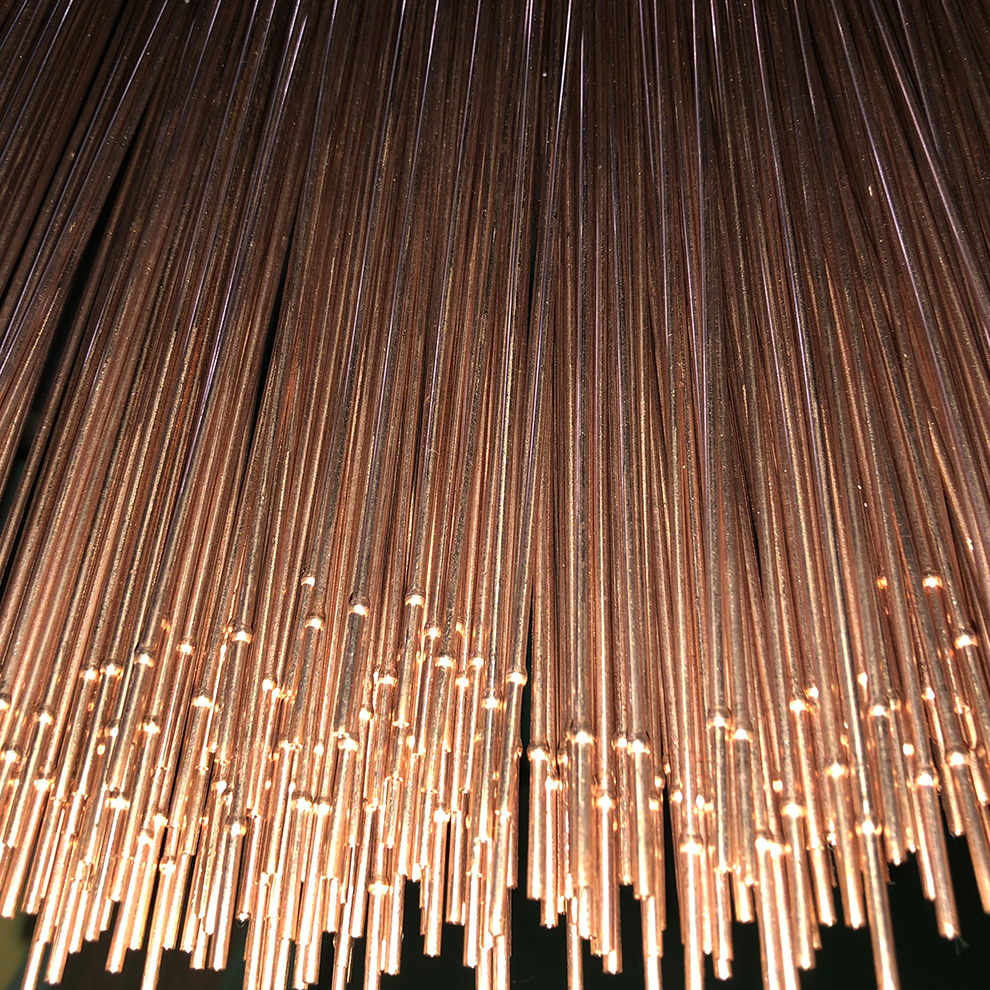

| Suitable capillary tube diameter | 1-3mm | |

| Suitable capillary tube length | Customized | |

| Feeding method | Manual operation | |

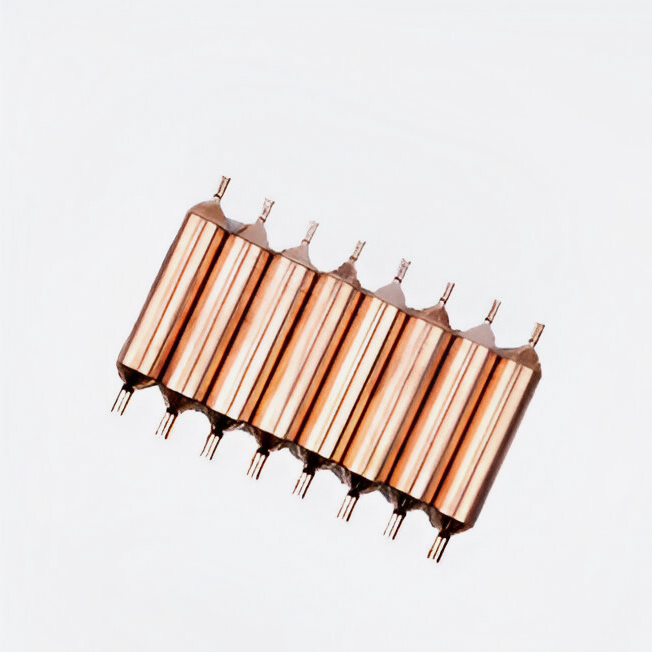

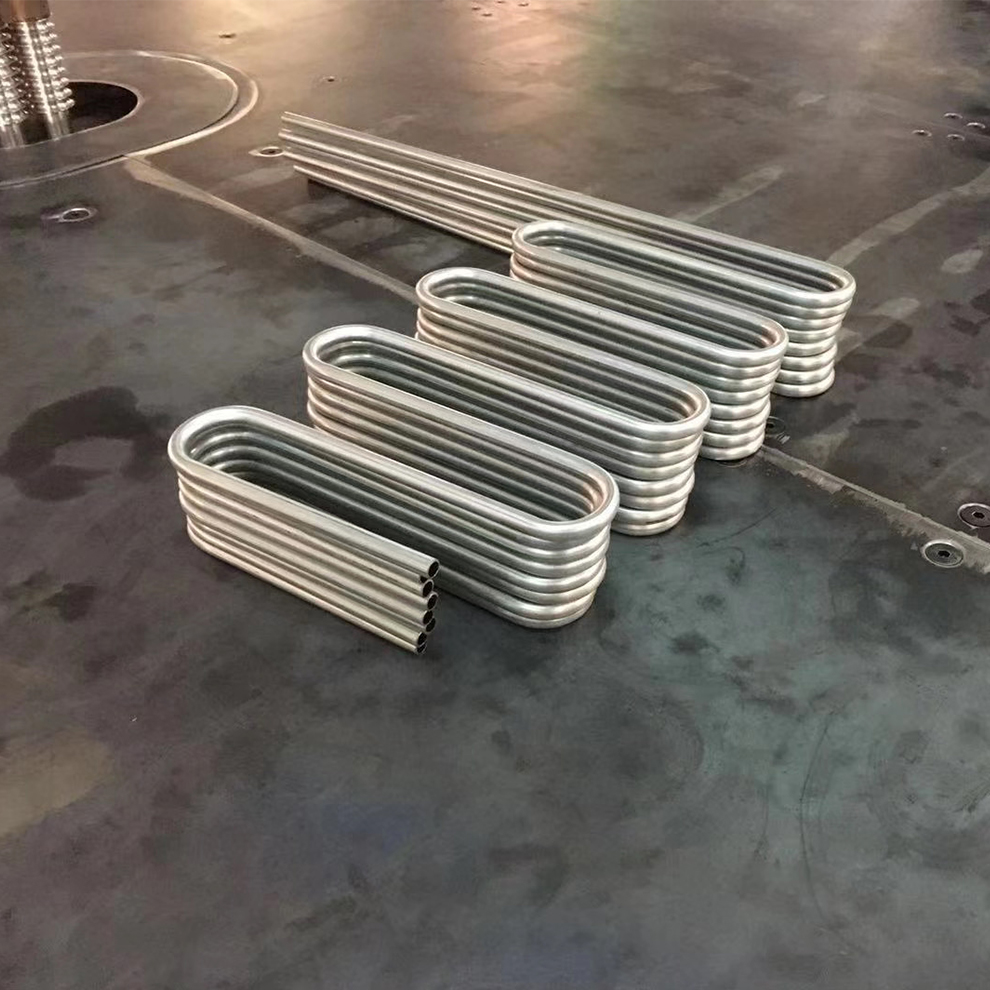

| Forming style | Customized | |

Item | Parameters | |

|---|---|---|

| Work Speed | About 2 seconds each | |

| Main power | 1.5kW | |

| Dimension | 450mm*650mm*1300mm | |

| Weight | 480kg | |

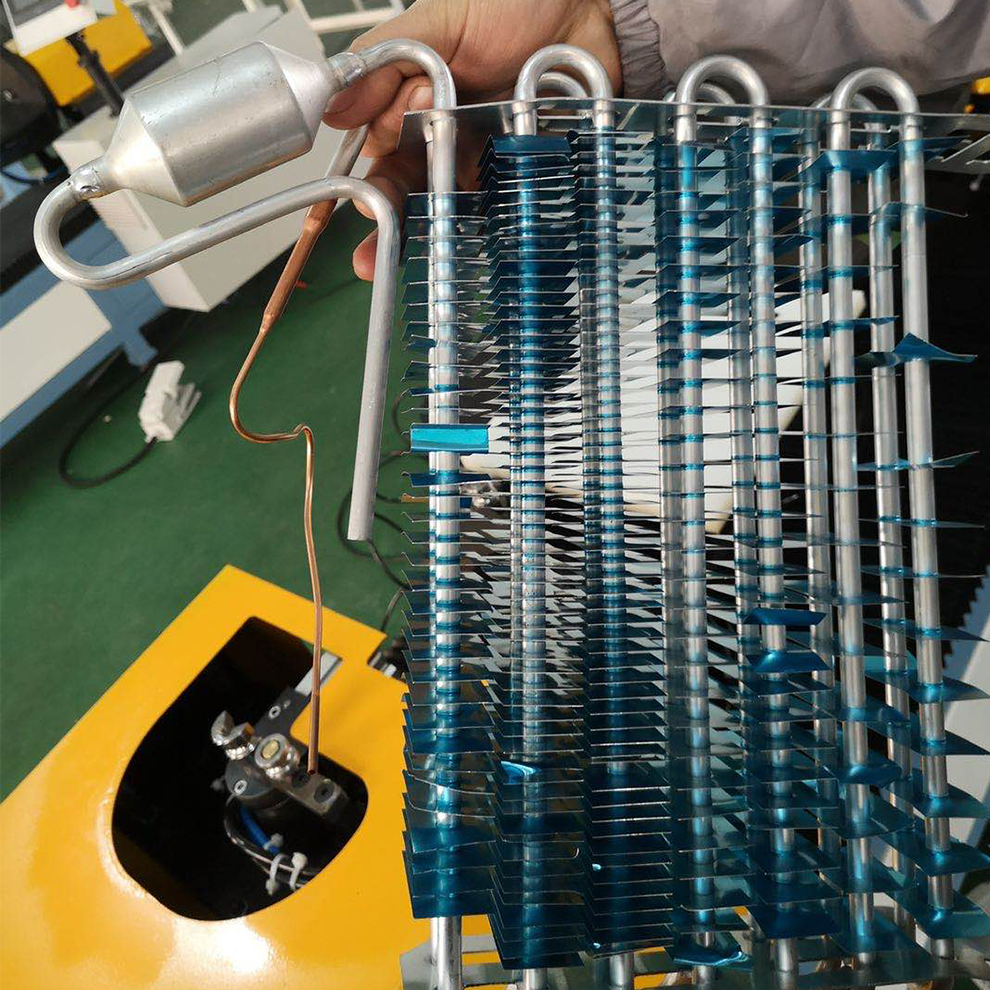

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.