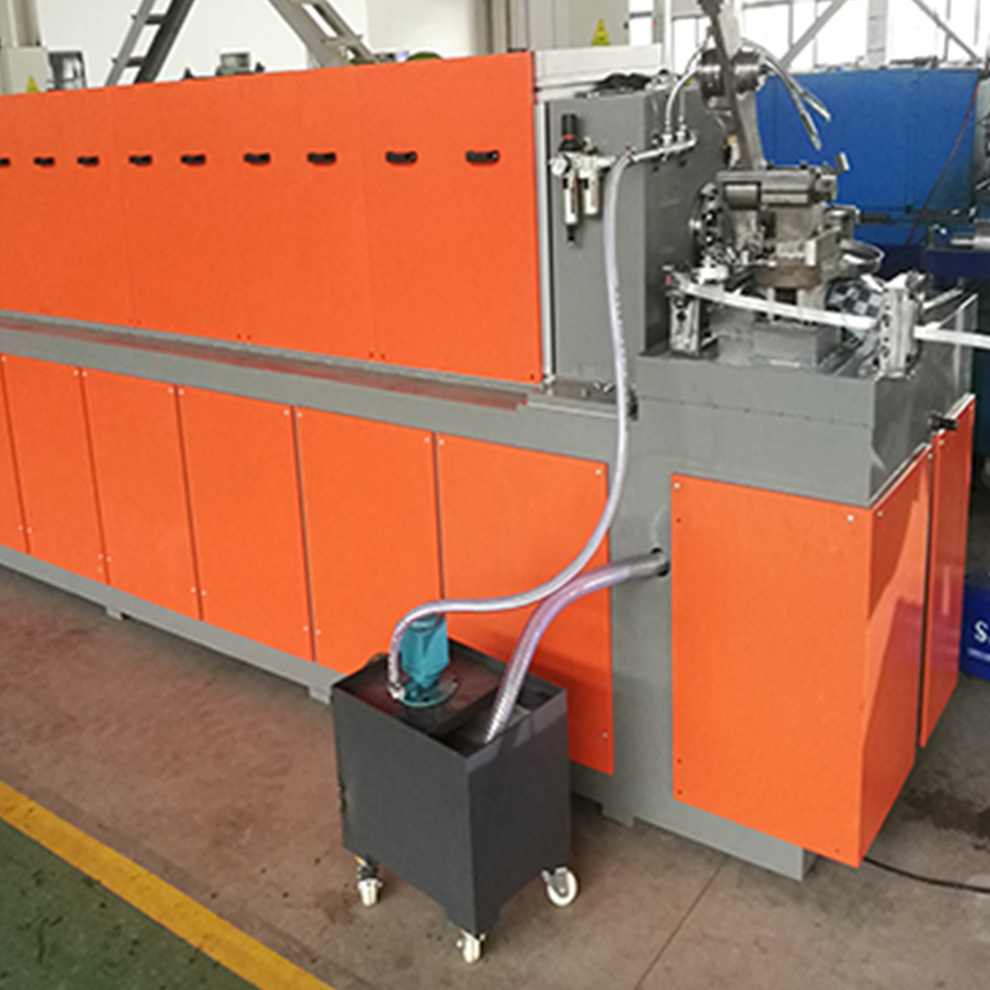

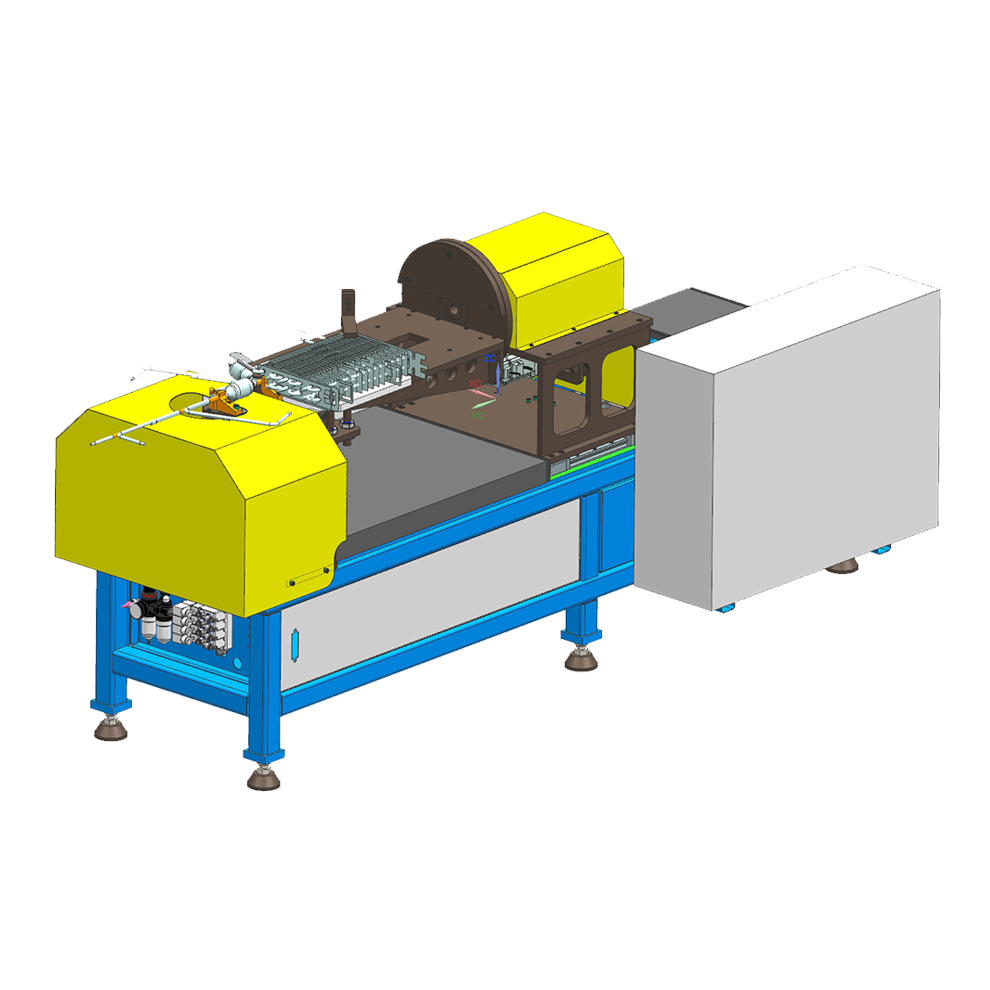

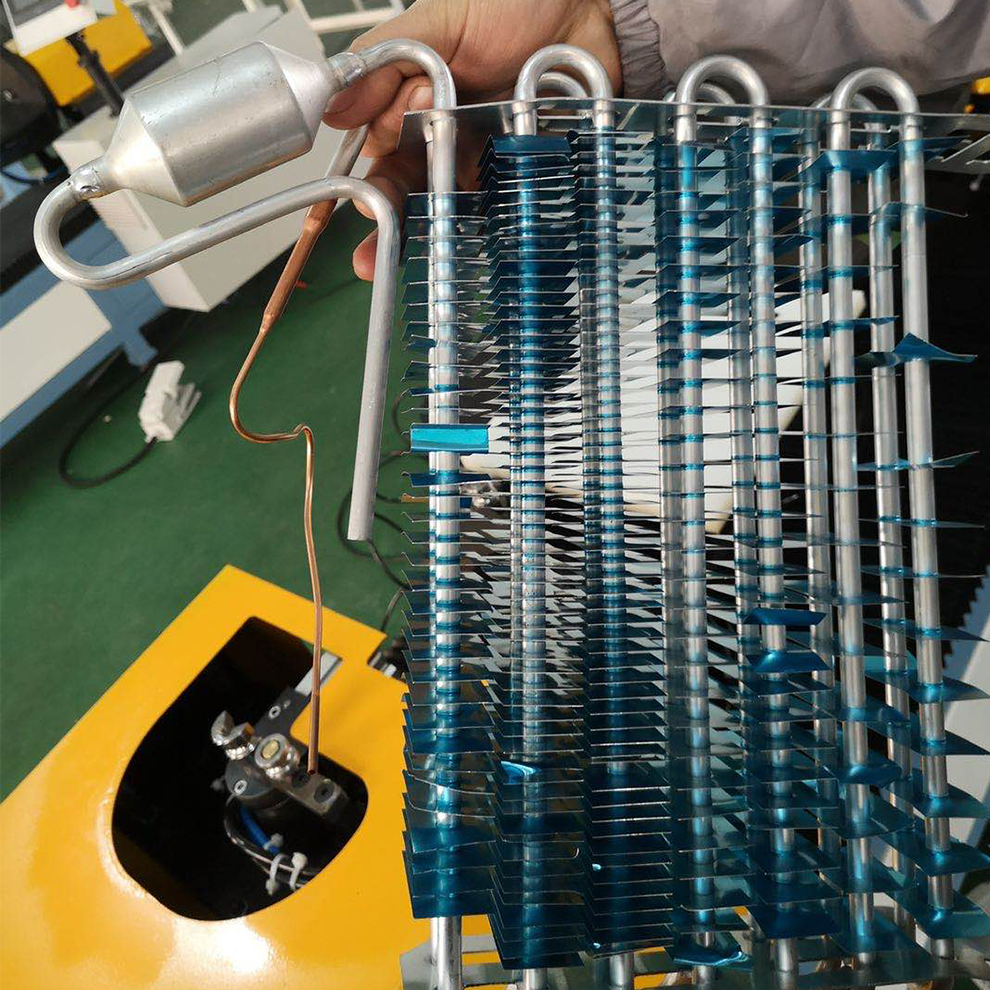

Multi-function Fin Tube Forming Machine

The equipment adopts stepless transmission to control the tightness of the warping piece, so that the warping piece is tightly wound on the smooth tube. The frequency conversion motor is used to adjust the range of pitch (2.3 ~ 5mm), with uniform pitch and high precision. The transmission adopts screw rod and rolling to drive the car to move around circularly. Gearbox; adopt self-developed forward and reverse power transmission system.

Parameter

Item | Specification | |

|---|---|---|

| Maine machine dimension | 4950×900×1500mm | |

| Loading table | 580×900×1000mm | |

| Axis distance | 1000mm | |

| Maine axis speed | 800r/min | |

| Feeding speed | 1200mm/min | |

| Precision | 0.01mm | |

| Pitch | 2.31~6mm | |

| Fin height | 8~16mm | |

Item | Specification | |

|---|---|---|

| Basic tube OD | 14-50.8mm | |

| Feeding device diameter | Φ19~Φ38 mm | |

| Feeding stroke | 1000mm | |

| Main motor | 11kw | |

| Feeding motor | 3.7kw | |

| Cooling motor | 120w | |

| Smoothing pump motor | 180w | |

Features

Vibration-Proof Structural Integrity

Adaptive Zero-Slip Feeding

Mitsubishi-Integrated Intelligence

Multi-Material Production Capacity

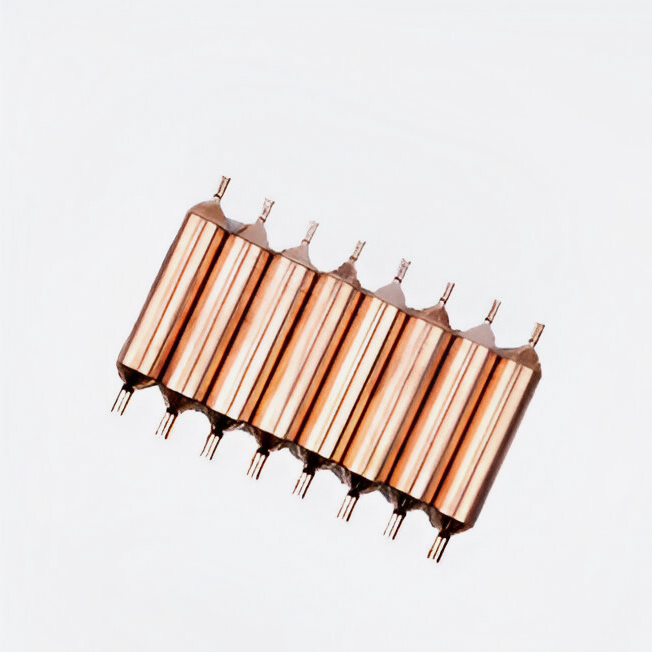

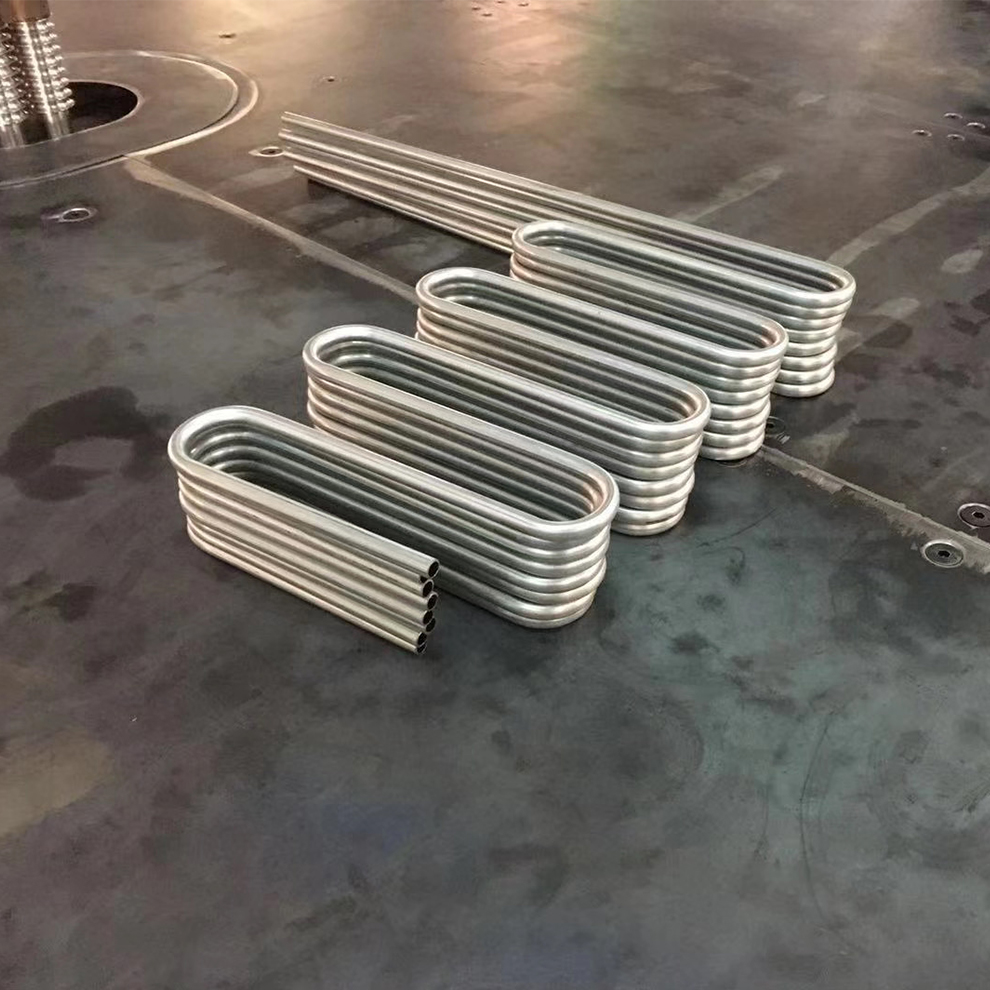

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.