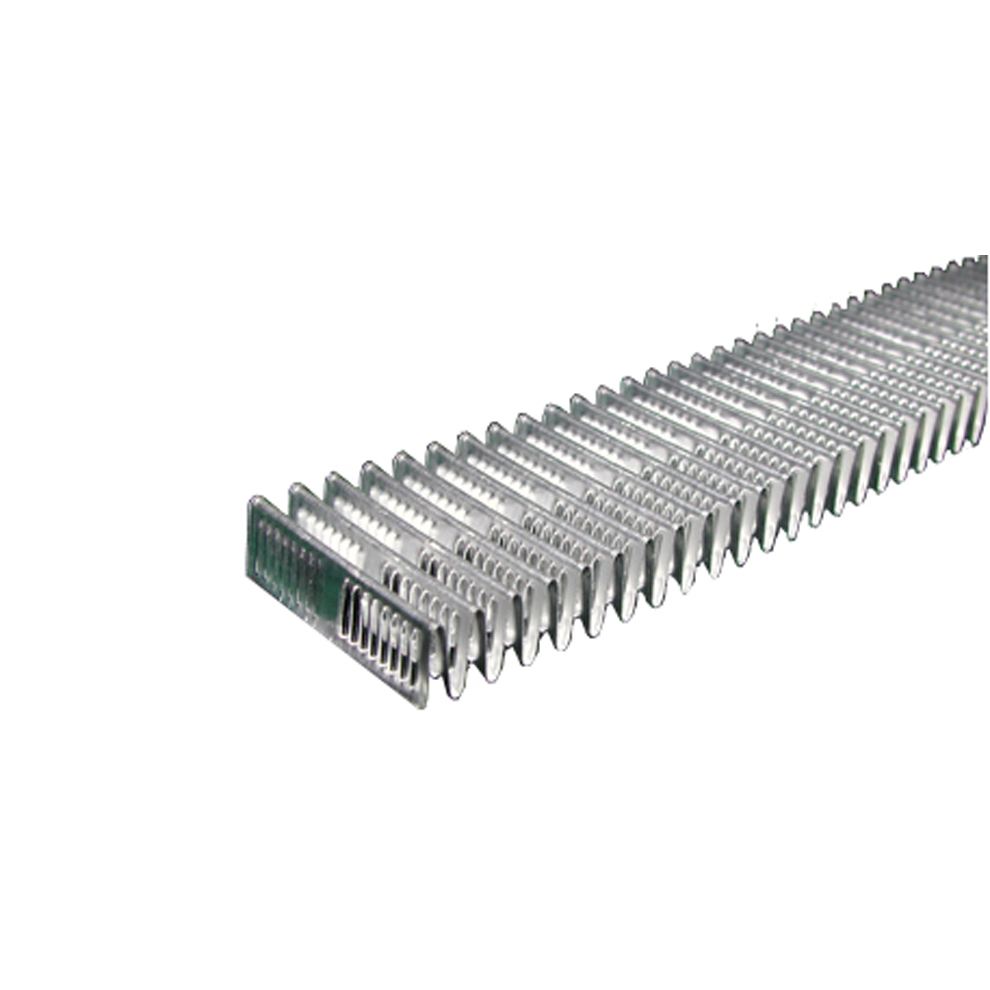

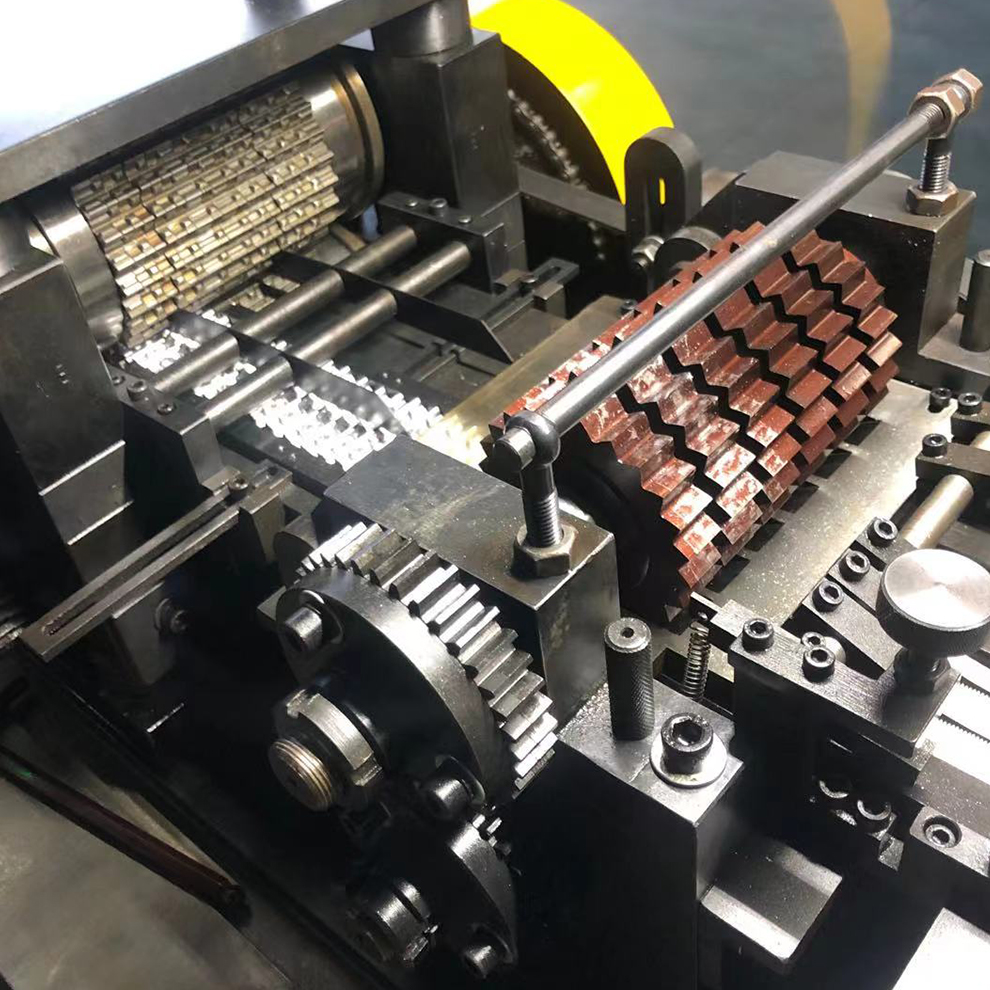

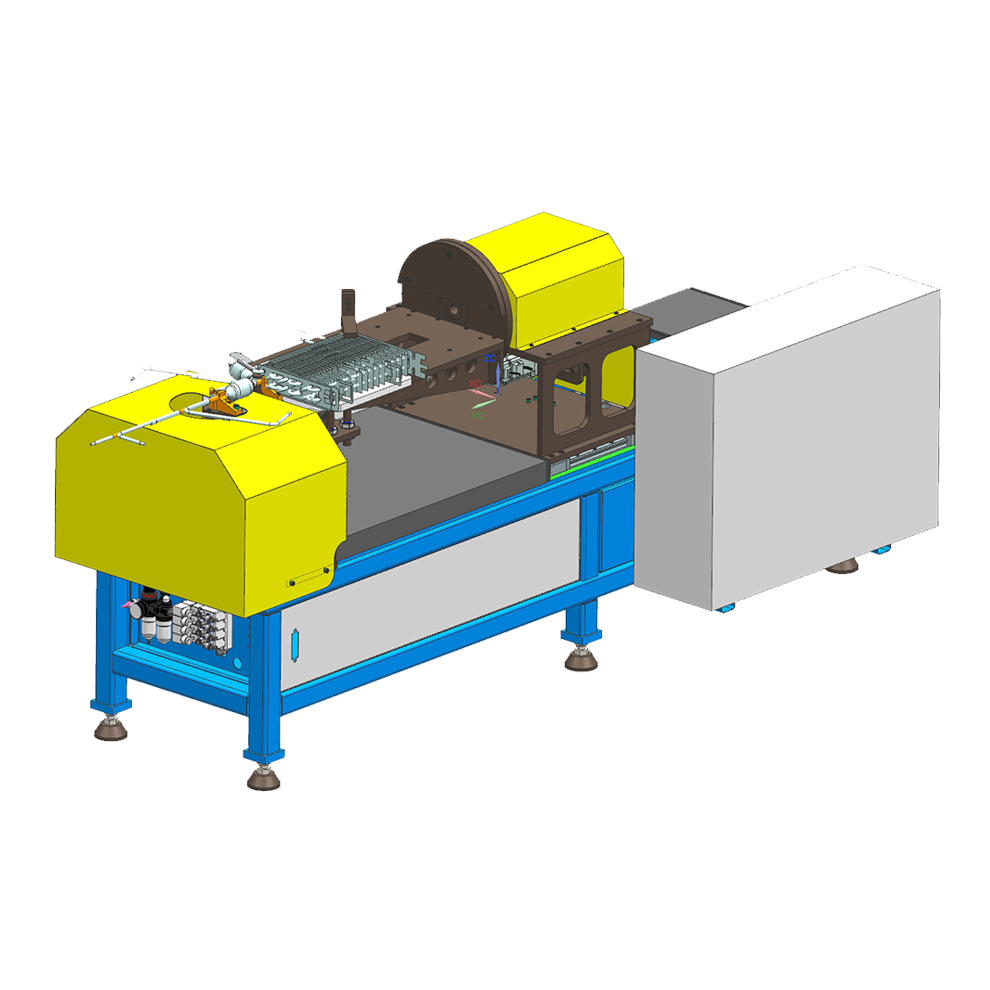

Radiator Fin Rolling Mill

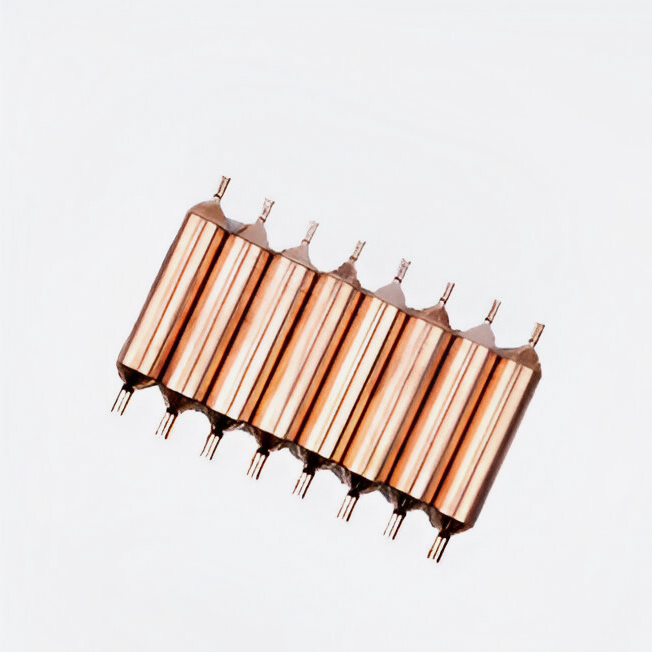

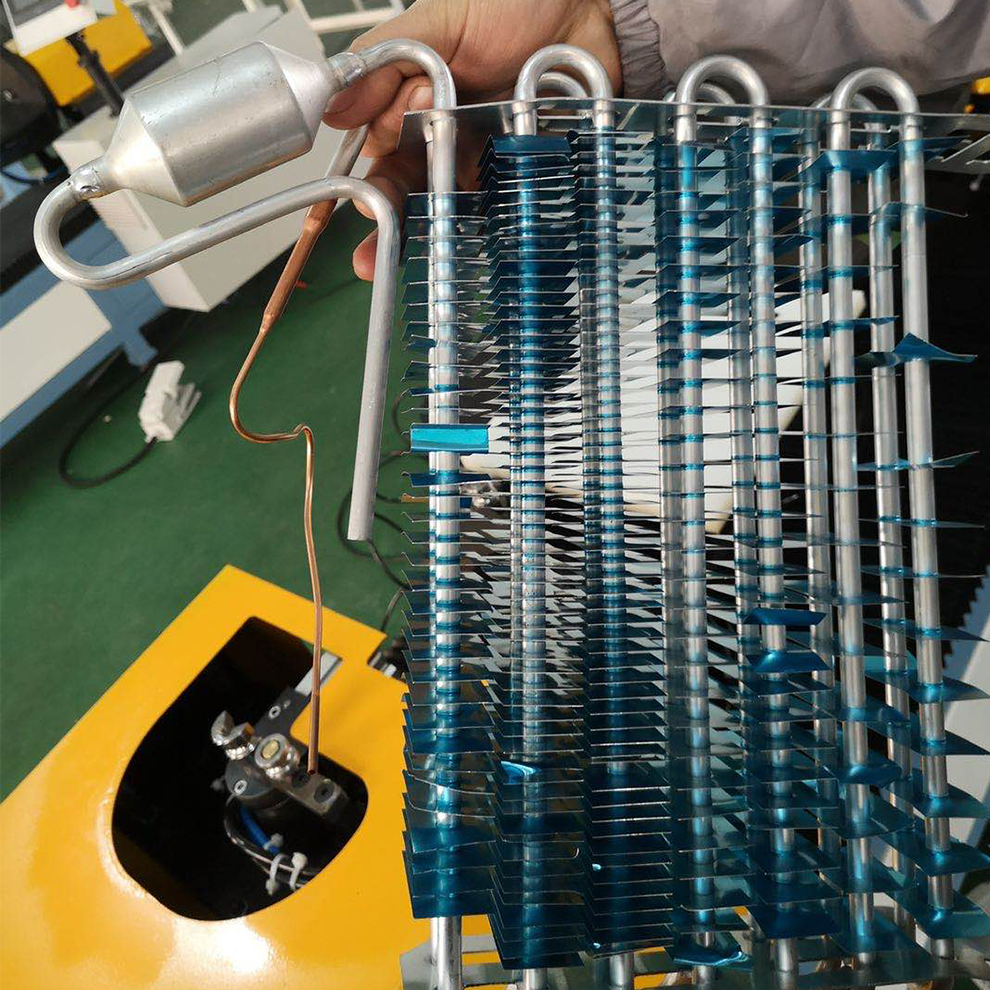

TheRadiator fin making machineis used to produce heat exchange wavy fins with or without windows. For radiators of Automotive, Truckand so on.

The following devices: decoiler, tensioning device, feeding, interval oil lubrication, fin forming, correction and cuttig function, strip run-out detection, blockage detection device, cutting fault indicator, fin forming unit overloading protection device, and fault indication light.

Parameter

Parameter | Data | |

|---|---|---|

| Fin wave height | 8.05mm ± 0.02 (customized) | |

| Fin width | 16mm/26m/32/56mm (Customized) | |

| Wave pitch | 2.6-3.0mm (16mm); 2.8-3.2mm (26 mm) | |

| Feeding speed | 0-150m/min 1000-5000 Peak/min The processing speed is steplessly adjustable | |

| Cutting capacity | max. 80 times/min | |

| Cutting accuracy | error 0 wave is cut at the peak | |

Parameter | Data | |

|---|---|---|

| Copper foil thickness | 0.09~0.115mm | |

| Tool design running speed | 5000 waves / minute | |

| Tool design life | ≥ 250 million Crest | |

| Total power | 6.0KW | |

| Air pressure | 0.4-0.6Mpa | |

| Equipment dimensions | 4500*600*1600mm | |

| Equipment weight | 2 To | |

Features

Adaptive Feed Stability

Self-Optimizing Wave Formation

Zero-Downtime Tooling

Integrated Post-Processing

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

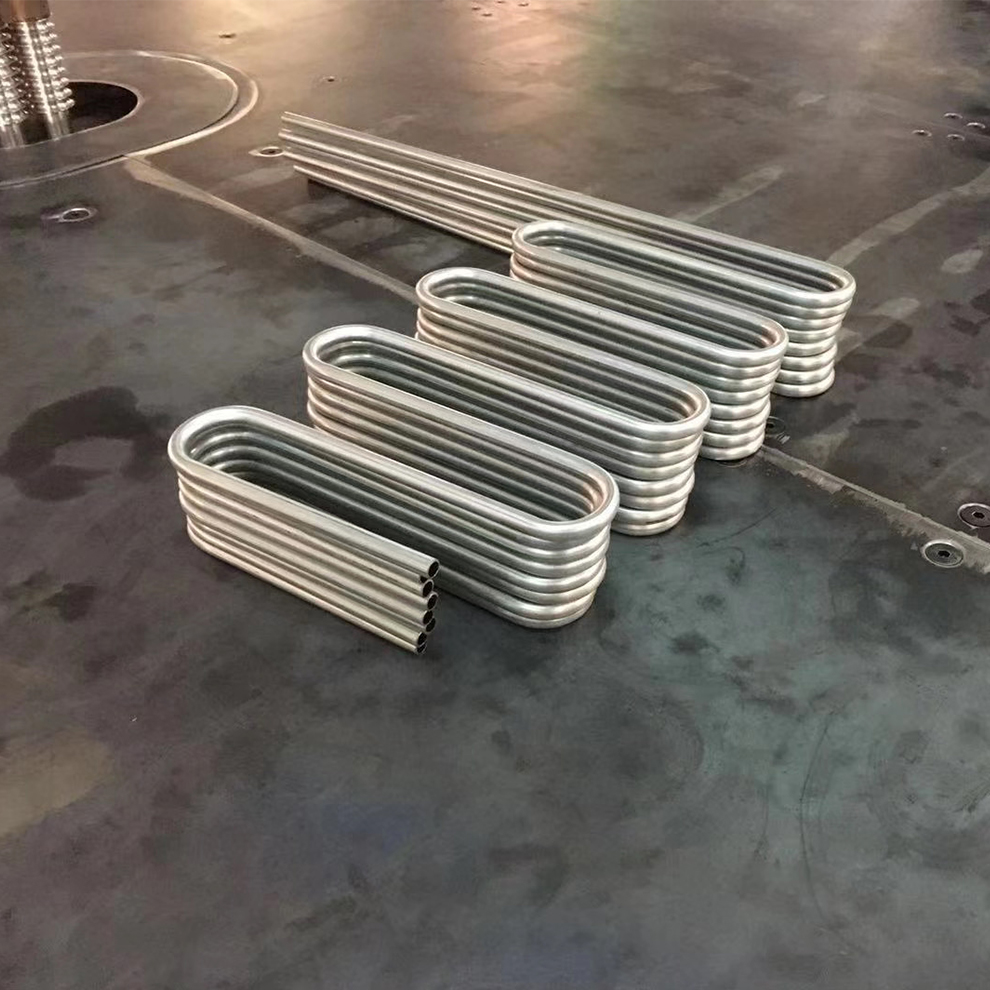

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.