Return Bender

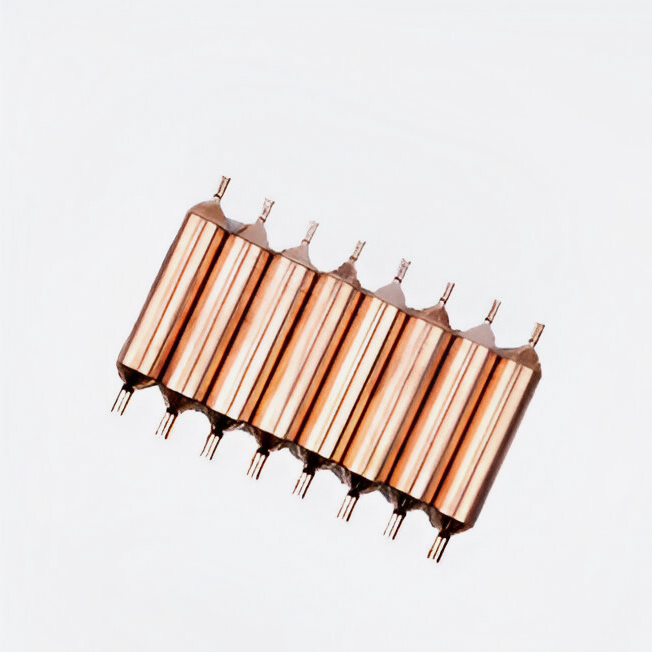

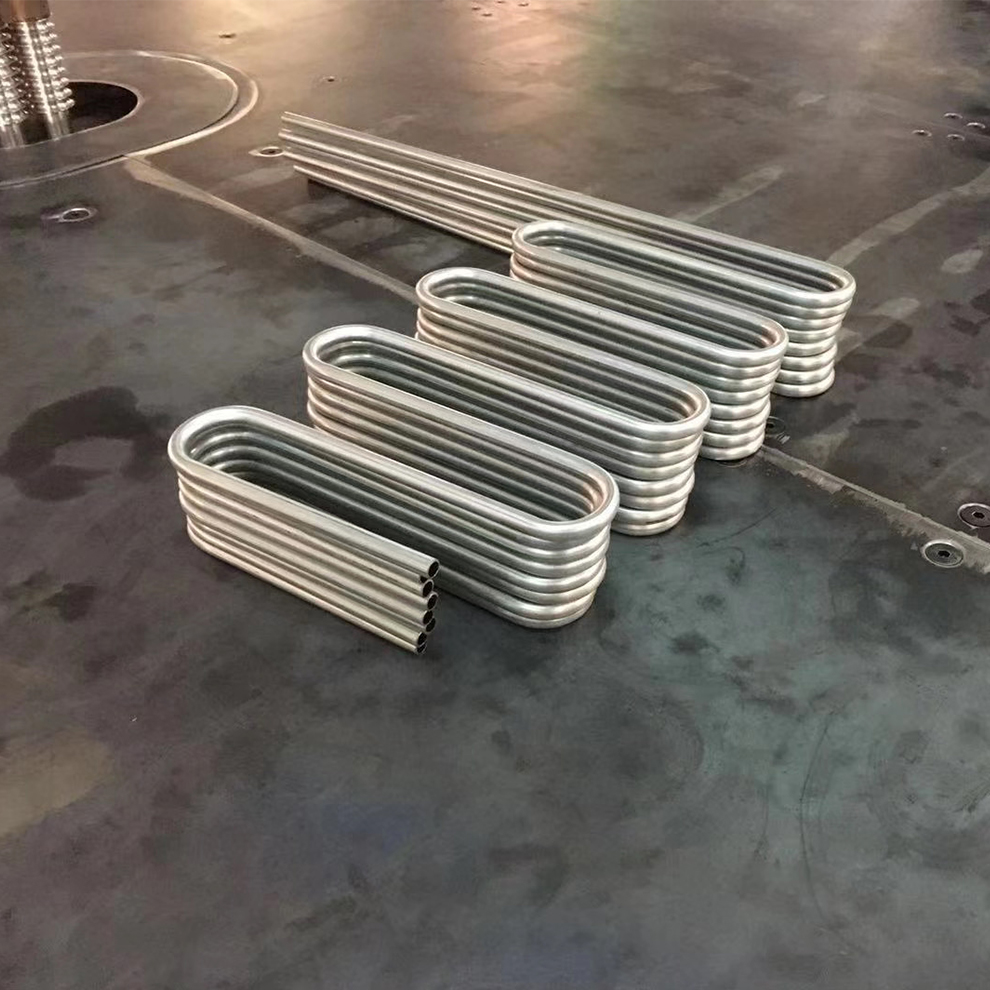

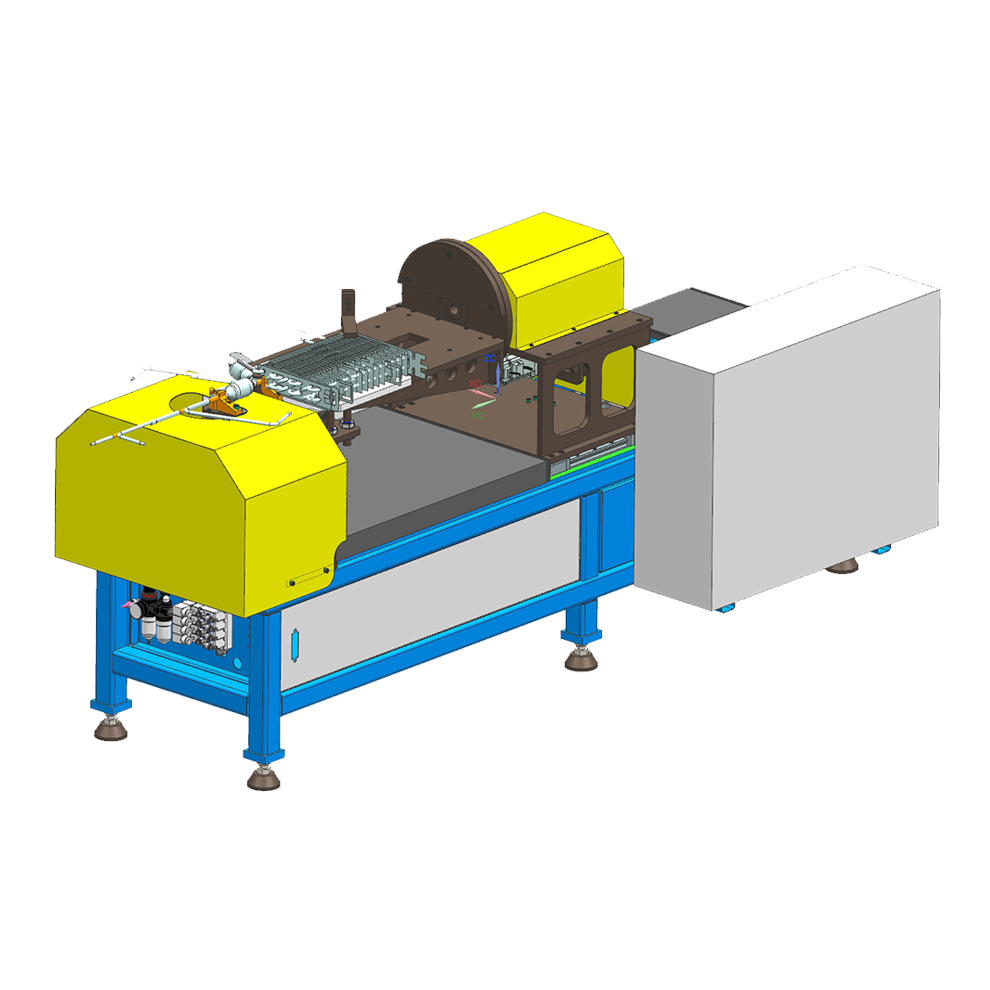

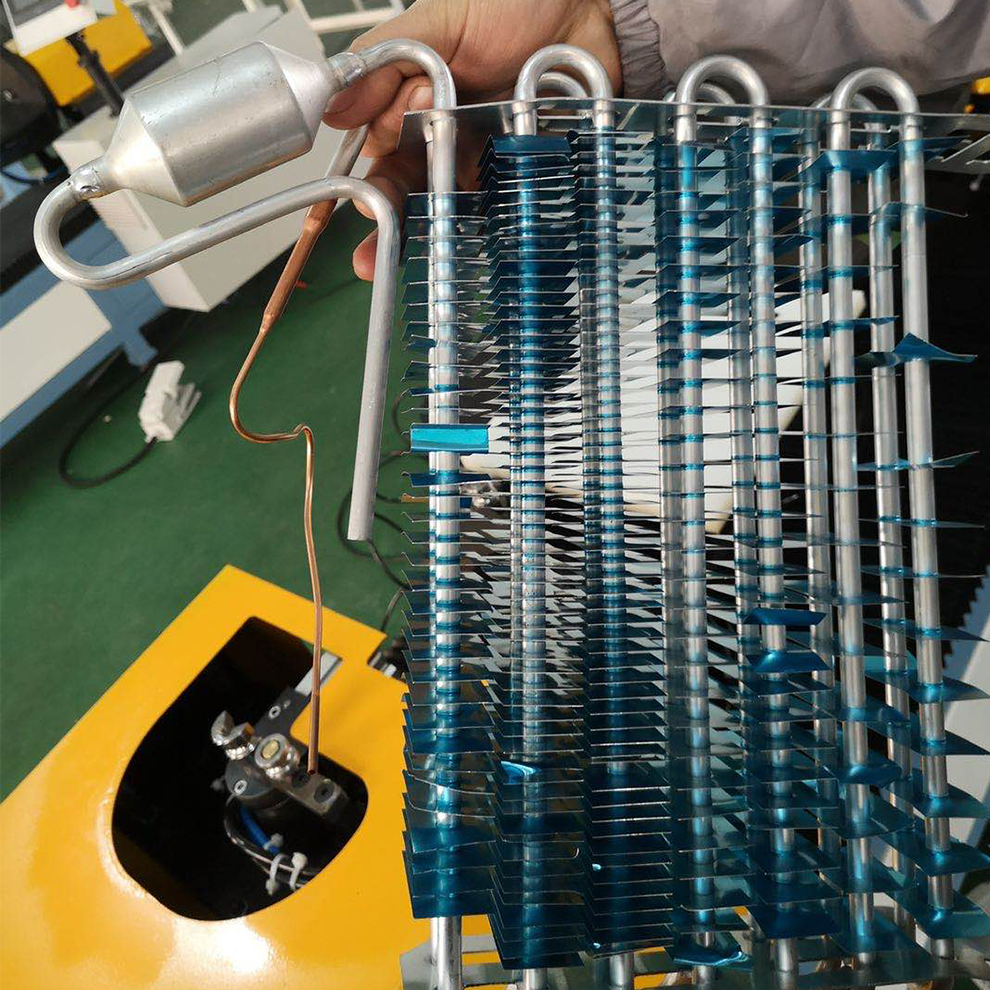

The equipment is mainly used in air-conditioning two devices, water heaters and other industries of small U tube of automatic production. Applicable to brass and thin-walled aluminum alloy pipe; the size of the coil copper tube straightening down; the copper tube bent into U-shape.

Parameter

Item | Specification | |

|---|---|---|

| Tube diameter | Φ 6.35Φ7Φ7.94 Φ9.52, (Or customized) | |

| Total power | 7.5KW | |

| Hydraulic power | 2.2KW | |

| Hydraulic pressure | 6-10mpa | |

| Cutting | Saw blade milling | |

| Bending capacity | 3-5Pieces | |

| Bending speed | ≤5s(one turn) | |

Item | Specification | |

|---|---|---|

| Ushape percision | ±0.1mm | |

| Oval rate | <15% | |

| Oval thickness less | <35% | |

| Control | CNC | |

| Voltage | AC380V | |

| Air pressure | 0.4-0.6Mpa | |

| *others requirements can be customized | ||

Features

Ultra-Flexible Tube Processing

Closed-Loop Bending Precision

Pneumatic Saw-Blade Cutting Integration

One-Touch Tooling Adaptability

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.