Tubing Machine

BoBo Machine offers you professional tubing equipment, such as tube cutting&straightening machines, pipe pressing machine, tube end forming machines, tube bending machines, tube welding machins and custom solutions for lines.

Contact Us NowTube End Expanding Machine

Forming by rotary swaging process.

Four-die design for less noise and better quality product.

Casted forming head housing ensure stable performance and long-life use.

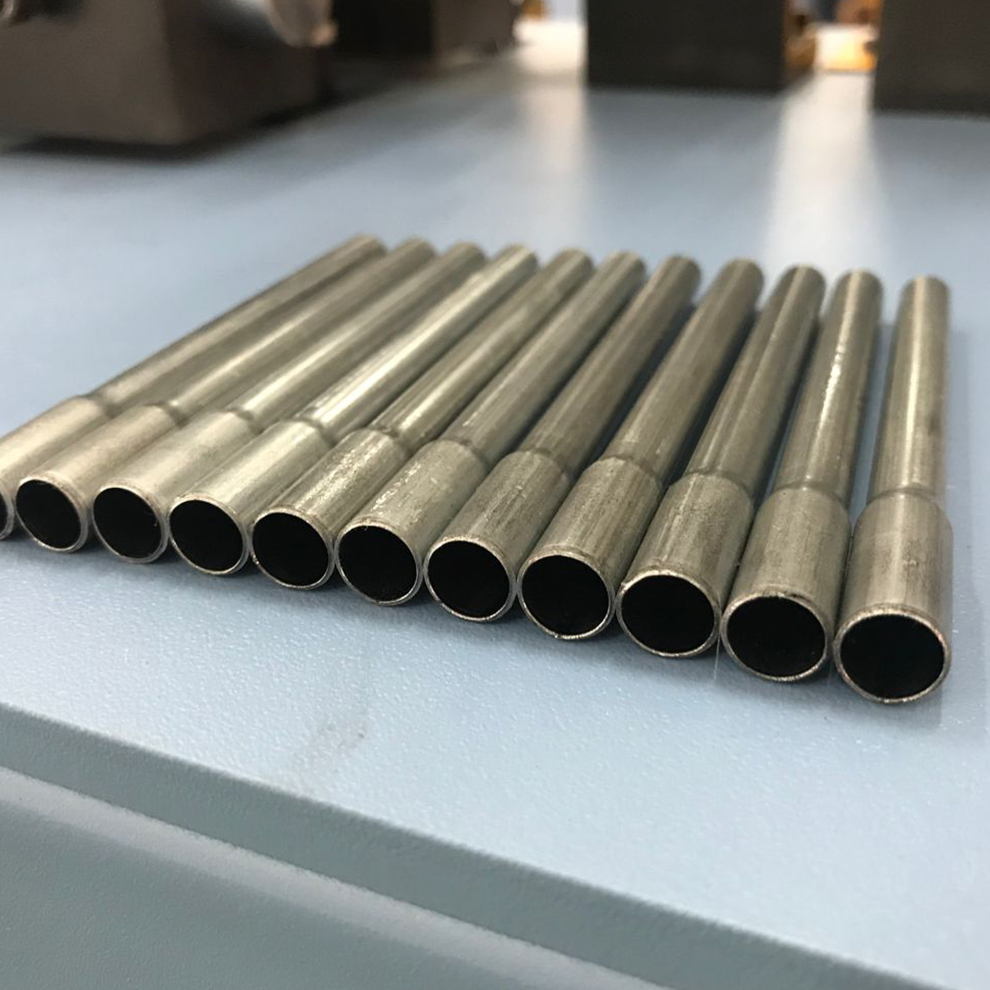

Tube End Shrinking Machine

Core-bar design to ensure the inner diameter during process.

Special designed forming die ensure welding quality with less waste.

Low noise of four-die design.

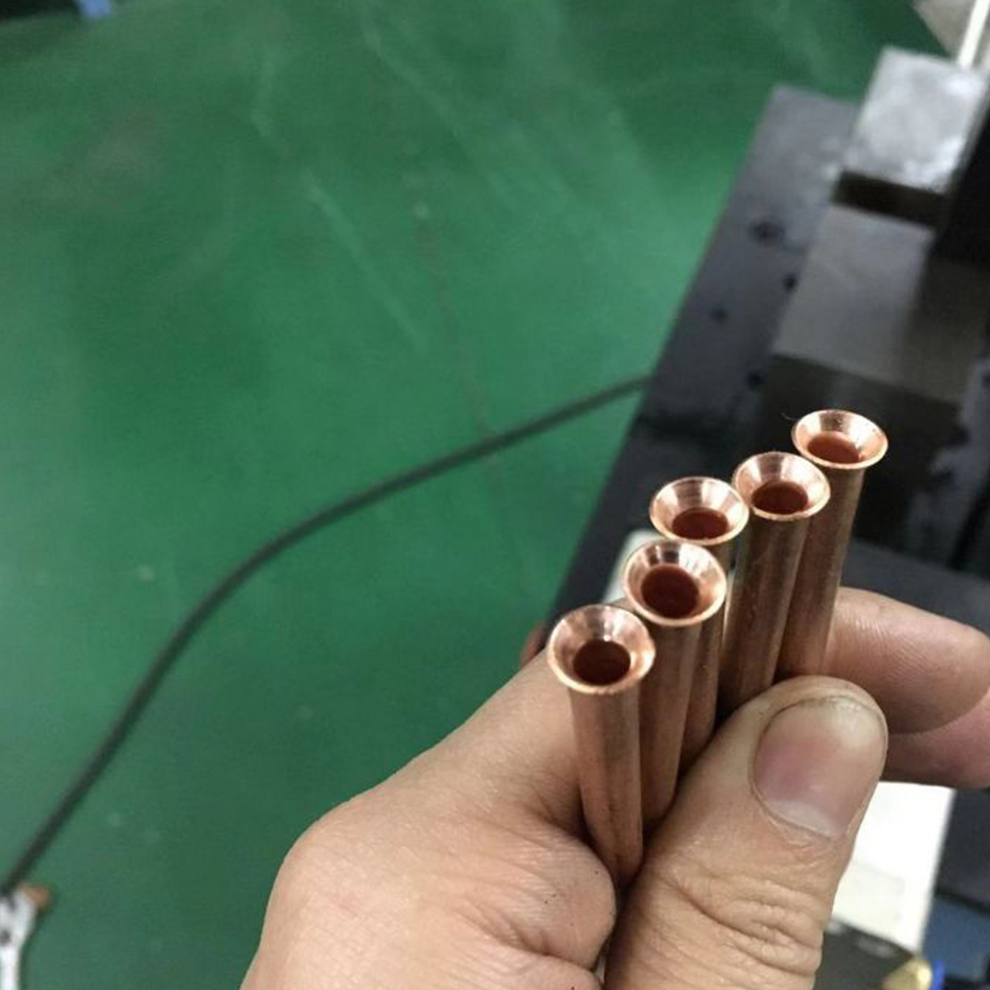

Copper Tube End Flaring Machine For Ac Connecting Pipe

Manual feed the tube into exact position with pneumatic positioner.

Die clamping the tube with side cylinder push and positioner cylinder recover.

The rotating motor start work and flaring head move forwarder with cylinder drive.

Double End Tube Chamfering Machine C-30

Special design and standardization of the blade make adjusting blade easily.

Automatic feeding, clamping and blade feeding and backing.

Quick and precise chamfering of end faces.

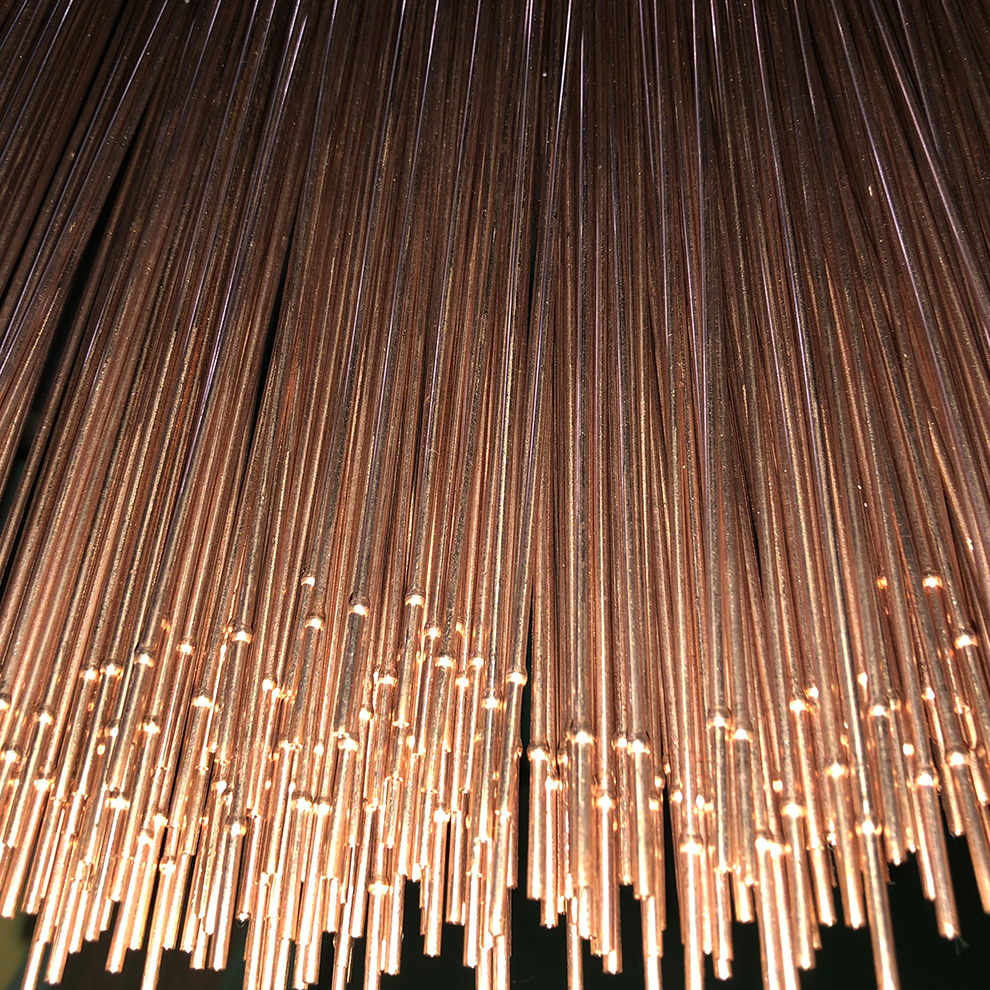

Copper Tube Spinning Machine

Automatically cut and trim the nozzle.

High degree of automation, With high work efficiency.

Convenient programming and stable and reliable performance.

Hydraulic Copper Capillary Tube Bulging Machine

Automatic pedal operation to ensure simple, stable and reliable operation.

Suitable for capillary tube with high precision.

Easy to change the tooling for different size.

Cooper Tube Drilling Flanging Machine D-50

NC programming, easy to operate.

One time forming,higher efficiency.

Chip-less cutting,no scars,no need clear.

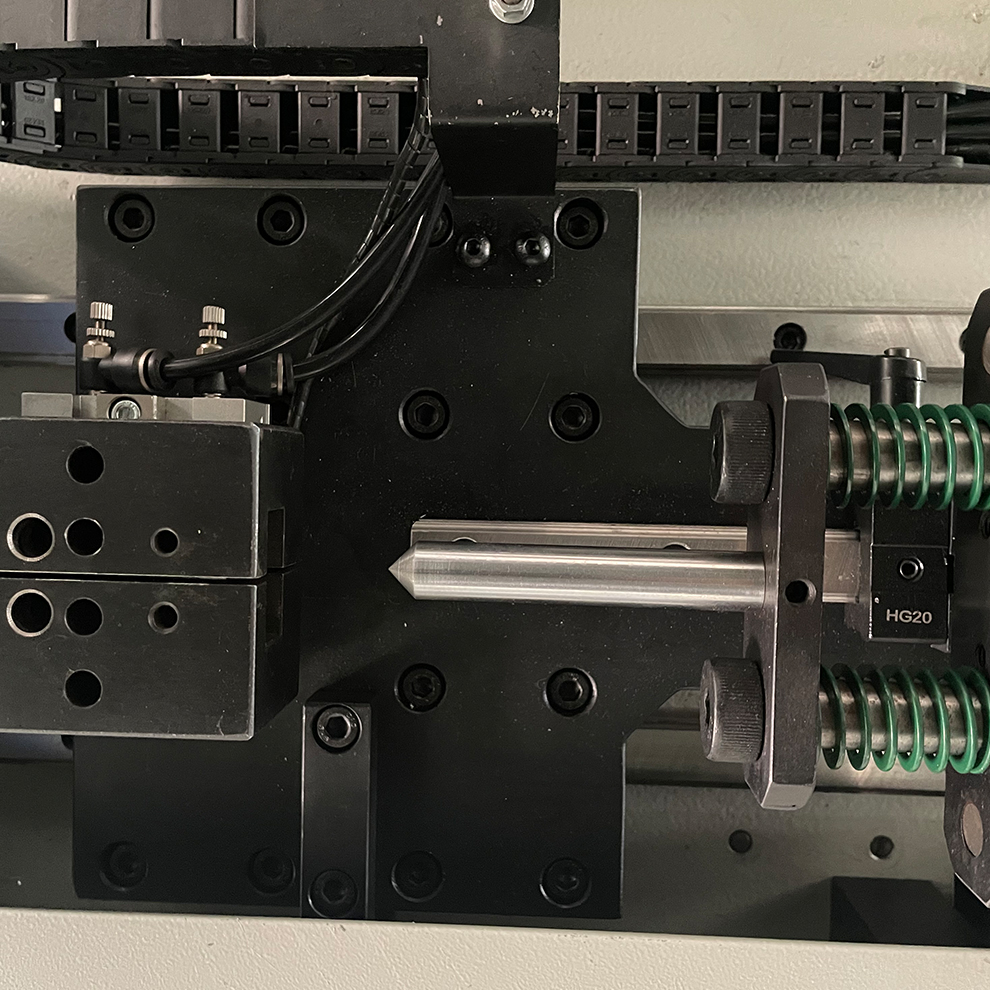

Dual Station Tube End Forming Machine

Four-die design, less noise and better product quality.

Casting forming head shell ensures stable performance and long service life.

Mandrel design to ensure the inner diameter during processing.

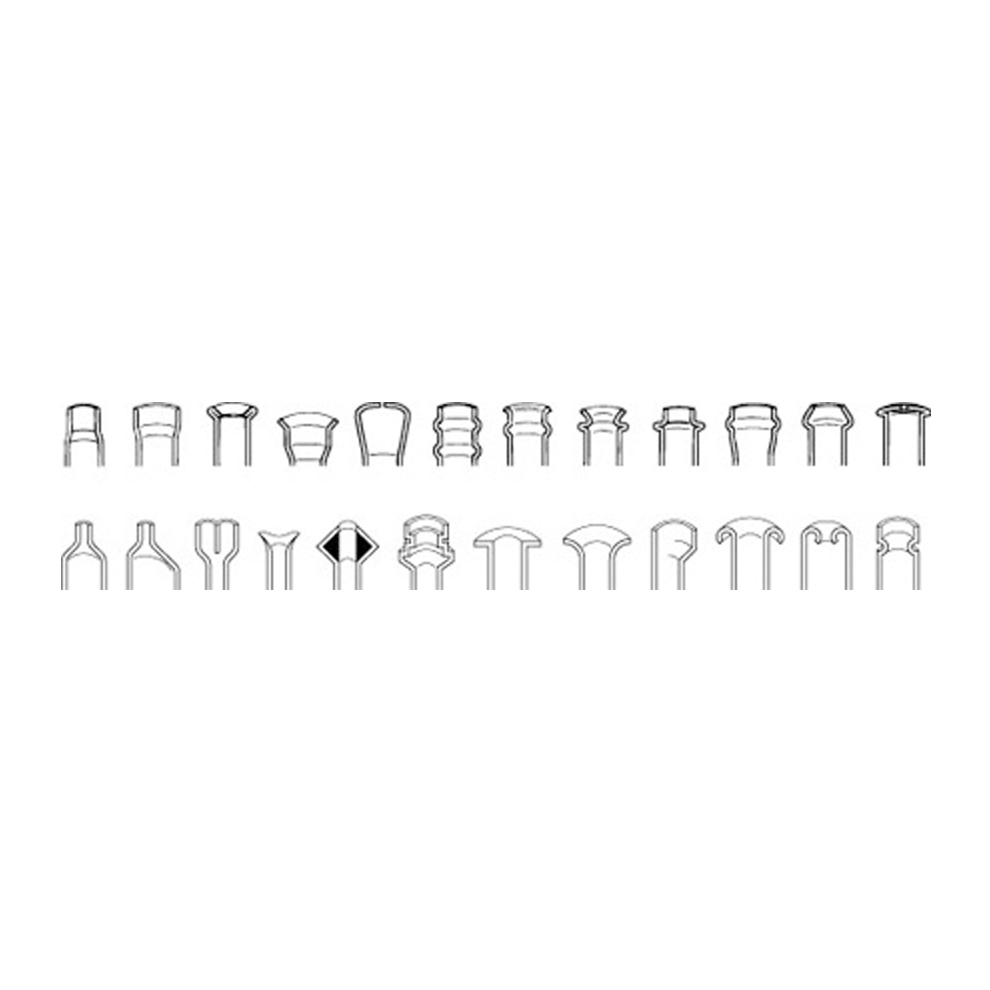

Multi-Station Tube End Forming Machine TEF-25T

Multi-stations enable to meet types of tube end forming.

Auto loading device to save time and labor.

The feed motion is driven by Siemens servo motor with high precision.