Tube Bender Vs Pipe Bender: What’s The Difference

Tube and pipe benders may look alike, but choosing the wrong one can lead to wasted material, inaccurate bends, and costly rework.

Understanding the difference is essential, especially in industries where precision, strength, and performance matter.

This guide breaks down how tube benders and pipe benders differ in purpose, design, and application so you can confidently select the right tool for every project.

What are Tube Benders

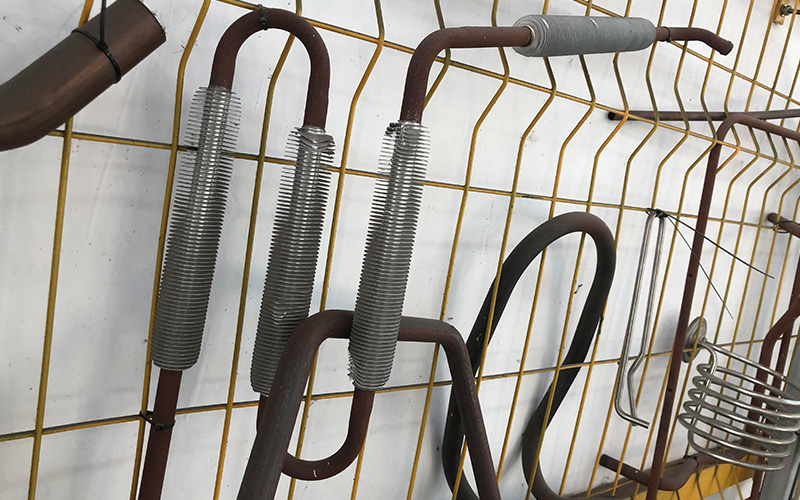

A tube bender is a tool that bends metal tubing into specific angles or shapes without flattening or crimping it.

It creates smooth bends that keep the tube’s round cross-section and internal diameter.

Tube benders are designed for tubing measured by outside diameter (OD) and often have thinner walls, requiring more precision.

They apply controlled force and often use dies or mandrels to prevent deformation.

Tube benders can be manual, hydraulic, or electric:

- Manual models use hand levers for small jobs or soft metals.

- Hydraulic versions provide more force for thicker or harder tubing.

- Electric or CNC benders offer high repeatability and accuracy for industrial use.

| Type | Power Source | Typical Use | Material Compatibility |

| Manual | Hand-operated | Small tubing, light work | Aluminum, copper |

| Hydraulic | Fluid pressure | Larger tubes, medium production | Steel, stainless steel |

| Electric / CNC | Motor-driven | High-volume, complex angles | Various metals |

Tube benders are common in automotive, aerospace, HVAC, and metal fabrication industries.

They help create parts like exhaust systems, hydraulic lines, and structural frames where precision matters.

What are Pipe Benders

A pipe bender is a tool that curves metal pipes into specific angles or shapes without breaking or flattening them.

It creates smooth directional changes in piping systems for plumbing, construction, or industrial use.

Pipe benders can be manual, electric, or hydraulic.

Manual models use hand force for light-duty work, while electric and hydraulic types apply higher pressure for thicker or larger pipes.

Pipe benders are designed for heavier walls and stronger metals, and they use inside diameter and schedule (wall thickness) as sizing methods.

Common materials include steel, copper, and aluminum.

| Type | Power Source | Best For |

| Manual | Hand-operated | Thin-walled or small pipes |

| Electric | Motor-driven | Medium-duty applications |

| Hydraulic | Fluid pressure | Heavy or industrial pipes |

Pipe benders are used in water supply, gas distribution, and manufacturing industries where precise pipe routing is essential.

Tube Bender vs Pipe Bender: Key Differences

The key differences between tube benders and pipe benders are listed below.

- Purpose and Applications

- Material Compatibility

- Design and Construction

Purpose and Applications

A tube bender forms bends in tubing for structural and mechanical uses, such as roll cages, furniture frames, and hydraulic lines.

Tubes require precise angles and smooth curves for strength and appearance, making tube benders ideal where accuracy matters.

A pipe bender bends pipes for fluid or gas transport, often used in plumbing, oil, and gas systems.

In these settings, flow capacity and proper alignment are more important than surface finish.

| Feature | Tube Bender | Pipe Bender |

| Typical Use | Structural and mechanical systems | Fluid and gas transport |

| Accuracy Needed | High | Moderate |

| Finish Requirement | Smooth, precise | Functional, less critical |

Material Compatibility

A tube bender works with metals like aluminum, steel, stainless steel, and copper tubing.

These materials offer lightness, corrosion resistance, or specific strength, and tubes usually have a uniform wall thickness and defined outer diameter.

A pipe bender handles thicker, harder materials such as carbon steel, galvanized steel, and heavy copper.

Pipes are rated by internal diameter and wall schedule, which affects how they deform under pressure.

Design and Construction

A tube bender uses dies and mandrels to support thin walls and keep the tube’s cross-section round.

Manual and rotary-draw designs give operators control of angle and bend radius.

A pipe bender has a heavier frame and larger die sets for high-pressure work, often using hydraulic or electric systems for thick materials.

- Tube bender: precise mandrels, smaller dies, smooth control.

- Pipe bender: rigid frame, large dies, more force capacity.

Important factors on how to choose a right bender

Select the right bender based on the tube or pipe’s physical properties, bend design, and required precision.Here some important factors you need to consider when choosing the right bender.

- The type of material

- The thickness of the material

- The outside diameter (OD) of the tube

- The centre line radius (CLR)

- The distance between bends

The type of material

The type of material means the metal or alloy being bent, such as steel, aluminum, stainless steel, or copper.

Harder materials like stainless steel need more powerful benders, while softer metals bend easily but need proper support to avoid deformation.

Operators should match the bender and tooling to the material’s strength and flexibility for best results.

The thickness of the material

Wall thickness measures the distance between the inner and outer tube surfaces and determines the force needed to bend the metal.

Thin-walled tubing can wrinkle under too much pressure, while thick-walled tubes need heavier equipment.

Using the right mandrels and dies helps maintain the tube’s shape and bend quality.

The outside diameter (OD) of the tube

The outside diameter (OD) defines the tube’s total width and affects die size, clamp force, and bending radius.

Benders are rated for specific OD ranges, and exceeding those can damage the equipment or tube.

Smaller diameters allow tighter bends but may distort, while larger tubes need more space and power.

The centre line radius (CLR)

The centre line radius (CLR) is the bend radius measured from the tube’s center to the curve’s centerline.

A small CLR creates a tight bend, while a larger CLR makes a smoother curve with less stress on the tube walls.

The recommended CLR is usually 2 to 3 times the OD for most materials to avoid ovality or collapse.

The distance between bends

The distance between bends is the straight section separating one bend from another.

This spacing affects how the tube fits in the assembly and whether the bender can position the tube for multiple bends.

Accurate measurement and proper spacing prevent interference and shape distortion, improving production efficiency.

Maintenance and Safety Tips

Here are some maintenance and safety tips to ensure smooth operation, accuracy, and long tool life.

- Regular cleaning removes dirt, oil, and debris after each use. Use a soft cloth and mild solvent to keep the bender clean and operating smoothly.

- Lubrication reduces friction between moving parts. Apply light machine oil to pins, hinges, and joints as recommended by the manufacturer.

- Inspection involves checking for wear, cracks, or alignment problems. Examine the bending die, frame, and hydraulic lines for damage.

- Calibration keeps the tool accurate. Use a protractor or gauge to test and adjust angle settings before large jobs.

- Safe operation depends on securing materials and wearing protective gear. Follow rated capacity limits to prevent damage or injury.

- Proper storage protects the tool from rust and damage. Store it in a dry location and keep dies and accessories organized in labeled containers.

Frequently Asked Questions

When to use tubing vs piping?

Tubing uses its outer diameter (OD) for measurement. Choose tubing for precise sizing, clean finishes, or structural strength in jobs like automotive, aerospace, and HVAC.

Piping uses its inner diameter (ID) and works best for transporting fluids or gases in plumbing, oil, and industrial systems. It focuses on flow and pressure rather than exact outside dimensions.

Use tubing for exact size or structural fit. Use piping for fluid transport and pressure-based systems.

Can you use a pipe bender for a tube?

A pipe bender is a tool designed to bend pipe to specific angles. It prevents the pipe walls from collapsing or kinking.

Pipe benders match pipe diameters and wall thicknesses made for fluid-handling systems. Some light-duty pipe benders can adjust to smaller diameters, but they lack the precision needed for tubing.

Tube benders provide tighter bends and keep the shape accurate for thin or delicate materials. Using a pipe bender on a tube can flatten or crack the tube because the tools have different tolerances.

For best results, always use the proper tool for each material.

Want to Know More About Our Products?

View All Products Now