What Are The Differences in Tube Brazing vs Welding Machine?

Introduction to Tube Joining Technologies

In industrial manufacturing, joining metal tubes is critical for creating robust systems like heat exchangers, condensers, and evaporators. Two primary methods dominate this process: tube brazing and welding. Each employs specialized machines to achieve strong, reliable joints, but their approaches, applications, and outcomes differ significantly.

Understanding the distinctions between Tube Brazing vs Welding Machine technologies is essential for manufacturers aiming to optimize production efficiency, joint quality, and cost- effectiveness.

What Is Tube Brazing?

Tube brazing is a joining process that uses a filler metal with a melting point lower than that of the base metals. The filler, often a copper or silver-based alloy, is heated to a molten state and drawn into the joint via capillary action. The base metals remain solid, ensuring the joint retains the original material properties. Brazing typically operates at temperatures between 800°F and 2000°F, depending on the filler metal and application.

How Tube Brazing Machines Work

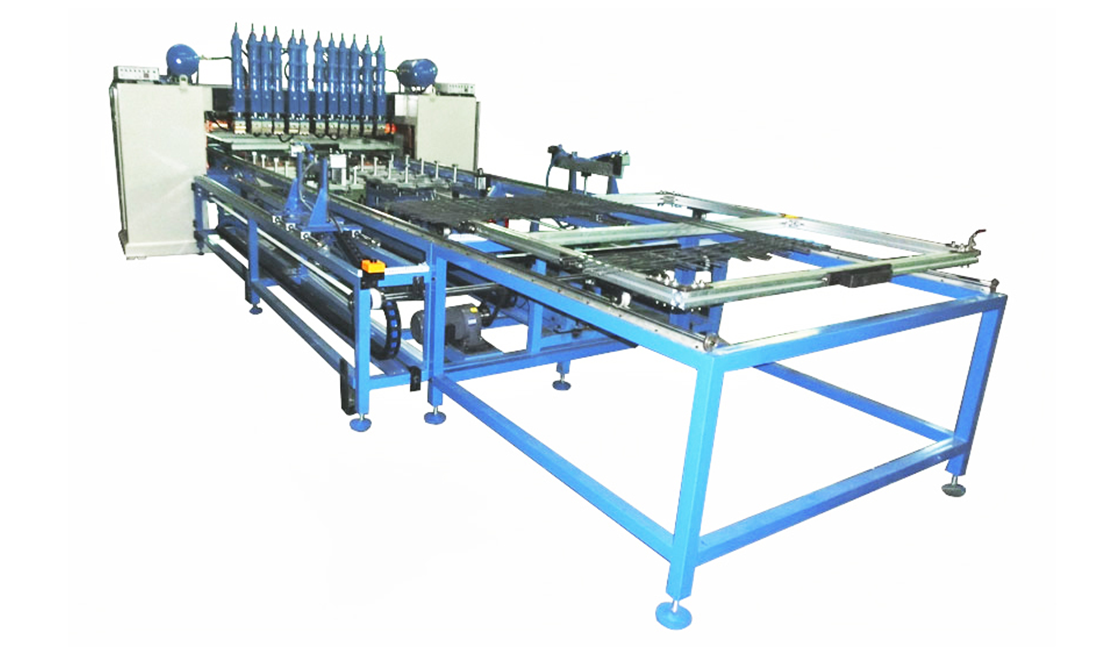

Tube brazing machines, such as the Gas Automatic Welding Machine HYQH-8000 from Bobo Machine, are designed for precision and automation. These machines feature a linear structure with components like a frame, drive system, transmission line, and fire exhaust combustion mechanism. They heat copper tubes, elbows, and welding rings continuously, allowing the filler metal to melt and fill gaps uniformly. Key features include:

Gas Control: Precise regulation of gas, oxygen, and nitrogen using systems like FLOTRON DF11K/MFC ensures stable welding temperatures.

Cooling Systems: Compressed air cools the welding zone, while water cools sliding rails and torches, enhancing equipment longevity.

Adjustable Torches: Multi-row welding torches, electrically adjustable, allow fine-tuning for various tube sizes and configurations.

These machines support 1–4 rows of workpieces, with conveyor belts adjustable for heights between 300–1600 mm, making them versatile for heat exchanger production.

What Is Tube Welding?

Tube welding involves fusing two metal surfaces by melting the base metals, often with a filler material. Common welding techniques for tubes include Gas Tungsten Arc Welding (GTAW or TIG) and orbital welding, which are widely

used in industries like power generation and petrochemicals. Welding operates at higher temperatures than brazing, often exceeding 6000°F, to achieve a homogenous bond.

How Tube Welding Machines Work

Tube welding machines, particularly orbital welders, automate the process for precision and consistency. These systems use a rotating electrode to create a uniform weld around the tube circumference. For example, in shell and tube heat exchangers, orbital welding ensures high-quality joints in tight spaces. Key features include:

Automation: Multiple weld heads can be operated sequentially by a single technician, increasing throughput.

Precision: GTAW welding delivers reliable, high-quality joints critical for high-pressure applications.

Material Versatility: Machines handle materials like stainless steel, titanium, and Inconel, common in heat exchanger construction.

Welding machines are ideal for applications where structural integrity is

paramount, such as nuclear power plants, where weld failure is unacceptable.

Key Differences Between Tube Brazing and Welding Machines

To select the right technology, manufacturers must compare Tube Brazing vs Welding Machine based on several technical criteria. Below, we analyze their differences across critical parameters.

1. Process Fundamentals

Brazing relies on capillary action to distribute molten filler metal between closely fitted tube surfaces. The base metals do not melt, preserving their mechanical properties. This process is ideal for dissimilar metals, such as copper and aluminum, commonly used in heat exchangers.

Welding, conversely, melts the base metals to form a single, continuous material. This fusion creates a stronger bond but requires compatible base metals to avoid issues like cracking or distortion. Welding is preferred for applications requiring maximum structural strength.

2. Temperature Requirements

Brazing operates at lower temperatures (800°F–2000°F), reducing the risk of thermal distortion and making it suitable for thin-walled tubes. The lower heat input also minimizes energy consumption, enhancing cost efficiency.

Welding, however, requires significantly higher temperatures (above 6000°F), which can cause heat-affected zones (HAZ) that alter the base metalʼs microstructure. This necessitates post-weld treatments like annealing to restore material properties, adding to production time and costs.

3. Equipment Design and Complexity

Brazing Machines are engineered for automation and continuous operation. For instance, Bobo Machineʼs HYQH-8000 features a conveyor system, multi- row torch configurations, and explosion-proof protections, making it suitable for high-volume production. The inclusion of gas leak alarms and automatic flame ignition enhances safety and reliability.

Welding Machines, particularly orbital systems, prioritize precision over speed. They incorporate advanced controls to manage weld parameters like arc length

and travel speed. While highly effective for complex geometries, their setup and operation require skilled technicians, increasing labor costs.

4. Joint Strength and Integrity

Brazed joints are strong but rely on the filler metalʼs properties. They excel in applications requiring leak-free seals, such as heat exchangers, where the joint must withstand thermal cycling but not extreme mechanical loads. The capillary action ensures uniform filler distribution, reducing defects.

Welded joints, due to their fusion nature, offer superior strength and are ideal for high-pressure or high-stress environments. However, weld imperfections like porosity or inclusions can compromise integrity if not properly controlled, necessitating rigorous quality checks.

5. Material Compatibility

Brazing is highly versatile, accommodating dissimilar metals like copper and aluminum, which are common in heat exchanger manufacturing. The use of copper or nickel-based fillers ensures compatibility across a wide range of materials.

Welding requires careful material selection to ensure compatibility. For

example, welding aluminum to stainless steel is challenging due to differences in melting points and thermal expansion. Specialized techniques like TIP TIG are often needed for such applications.

6. Production Speed and Efficiency

Brazing machines excel in high-volume production due to their automated, continuous operation. The HYQH-8000, for instance, can process multiple rows of tubes simultaneously, with conveyor speeds adjustable for optimal

throughput. Cooling systems prevent overheating, allowing uninterrupted operation.

Welding machines, while precise, are slower due to the need for controlled heat input and post-weld inspections. However, automation in orbital welding has improved efficiency, with systems capable of welding a 2-inch tube in 30 seconds or less.

7. Cost Considerations

Brazing is generally more cost-effective due to lower energy requirements, simpler equipment setup, and reduced need for skilled labor. The use of

automated brazing machines further lowers operational costs by minimizing reject rates.

Welding, while more expensive due to higher energy consumption and skilled labor requirements, is justified in applications where joint strength is non-

negotiable. The investment in advanced welding machines can be offset by their durability and precision in critical industries.

Applications in Industry of Tube Brazing and Welding Machines

The choice between tube brazing vs welding machines hinges on the job at hand. Hereʼs how they stack up in real-world use:

Tube Brazing Applications

HVAC Systems: Copper tubes in heat exchangers rely on brazing for leak- proof, corrosion-resistant joints.

Refrigeration: Aluminum-to-copper connections benefit from brazingʼs ability to join dissimilar metals.

Plumbing: Brazed fittings offer reliable seals without compromising pipe strength.

Tube Welding Applications

Automotive: Exhaust systems and chassis components demand welded steel for durability.

Aerospace: Stainless steel fuel lines use welding for uncompromised structural integrity.

Construction: Pipelines and frameworks lean on welded joints to handle stress and weather exposure.

Each machine type aligns with its strengths, driving efficiency in its niche.

Advantages and Limitations

Tube Brazing Machines

Advantages:

Lower heat input reduces distortion.

Suitable for dissimilar metals.

High automation improves efficiency.

Cost-effective for high-volume production.

Limitations:

Joint strength depends on filler metal.

Limited to applications with moderate mechanical loads.

Tube Welding Machines

Advantages:

Superior joint strength for high-pressure applications. Precise control ensures consistent quality.

Versatile for various tube sizes and materials.

Limitations:

High heat input risks distortion and HAZ.

Requires skilled operators, increasing costs.

Choosing the Right Machine for Your Needs

Selecting between Tube Brazing vs Welding Machine depends on several factors:

Application Requirements: For leak-free, moderate-strength joints, brazing is ideal. For high-pressure, high-strength applications, welding is preferred.

Material Types: Brazing suits dissimilar metals, while welding requires compatible materials.

Production Volume: Brazing machines excel in high-volume settings, while welding machines are better for precision tasks.

Budget: Brazing offers lower upfront and operational costs, while welding justifies higher costs in critical applications.

Consulting with experts, such as those at Bobo Machine, can help tailor the solution to your specific needs, ensuring optimal performance and cost efficiency.

Impact on Manufacturing Efficiency

Both tube brazing vs welding machines influence production outcomes differently:

Brazing: Speeds up assembly with quick cycles and minimal cleanup. Its energy efficiency also cuts operational costs.

Welding: Ensures long-term reliability, reducing maintenance or failure risks. However, it demands more setup time and skill.

Balancing these factors optimizes throughput and product lifespan.

Conclusion

The differences between tube brazing vs welding machines boil down to their core mechanics: brazing bonds with a filler at lower heat, while welding fuses metals with intense energy. Each excels in its domain—brazing for versatility

and efficiency, welding for strength and precision. By aligning your choice with project demands, you enhance quality and performance. For tailored advice or cutting-edge equipment, reach out to experts who understand these technologies inside out.

Need help picking the perfect tube brazing vs welding machine for your

operation? Contact Bobo Machine. Our team specializes in heat exchange and tube processing solutions, offering top-tier welding and brazing machines to elevate your manufacturing. Visit www.heat-exchange.com for more details and get started today!

Want to Know More About Our Products?

View All Products Now