What Should a Tube Welder Pay Attention to While Using a Tube Welding Machine

Welding tubes are important and necessary for various industries, from HVAC systems and heat exchangers to radiators and other systems involving tube and pipe assemblies. Tube welders must be highly skilled and aware of several technicalities and critical aspects of using a tube welding machine. We will cover what a tube welder should focus on when using a tube welding machine. We’ll also cover some practical tips to help tube welders improve their quality of work.

Tips for Using Tube Welders For Rightly Using Tube Welding Machine

Tube welding machines are easy to use for tube welders, but if they don’t pay attention to minor details, they will definitely be unable to achieve the desired results.

Tube Welding Machines and their settings

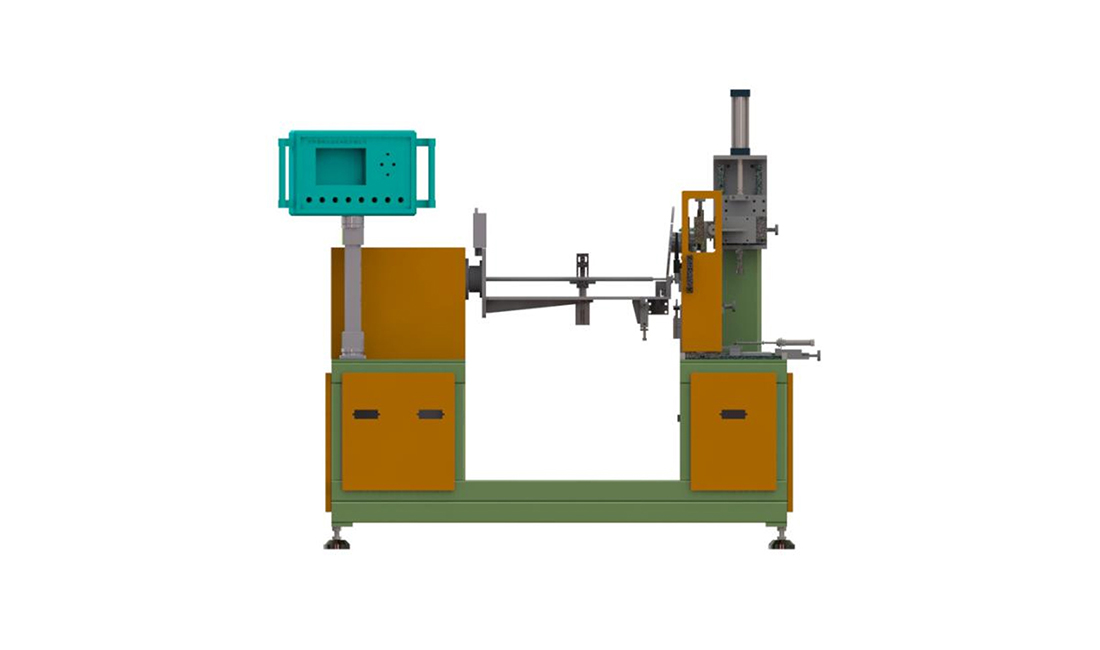

Tube welders have the general idea of welding machines, but how to operate them rightly as each machine is different from others, they must learn the correct process. The welders need to go through the basic features of these machines and understand how to adjust their settings. Different welding machines have different temperature controls, voltage, and speed. The correct setting of the machine selection is based on the material of the tube being welded, whether it’s copper, aluminum, or stainless steel. Tube welding machines are of different types, which are as follows.

- Resistance welding machines: These machines join metals by applying pressure and passing a current through them.

- TIG welding machines: The Tungsten Inert Gas machines offer precise and clean welds.

- MIG machines: Metal inert gas machines are best for fast welding with some flexibility.

Material Selection:

Before any welding is commenced, a tube welder should be well-versed with the available tube materials in order to make the correct decision. The welder is required to select the welding technique based on the material of the tube. The types of materials constituting the tube are stainless steel, copper or aluminum and these particular materials determine the appropriate form of welding for tube welding. For example

- Stainless steel tubes need careful temperature control to prevent burn-through. Its durable nature requires a clean, stable weld to offer structural integrity.

- Copper tubes require a different electrode or shielding gas. Copper material has a high melting point and requires a different technique than aluminum tubes with a lower melting point.

The BOBO tube welding machines handle a variety of materials with adjustable settings. It makes high-quality welds possible regardless of the material.

Proper Tube Alignment

Tube welding requires precision. A welder should accurately align the tubes and fix them in the correct position by using fixtures or clamps. If the tubes are misaligned during welding, you will get weak and inconsistent results, and it may overall offer defective welds. Some tube welding machines have advanced clamping systems, which help welders achieve optimal alignment with ease. By focusing on tube alignment, the welder gets strong, accurate welds every time.

Cleaning Tubes

Tubes have often oil, rust and dirt on their surface. These surface contaminants during welding can cause issues in offering quality results. Proper cleaning of the tube is important to remove these contaminants before welding. Tube welders thoroughly clean the tube by using different methods depending on the type of material used:

- Wire brushing is the best method for removing rust or surface dirt.

- Tube welders choose acid pickling, which is beneficial to use for cleaning stainless steel tubes.

- They use various solvents to remove oils or grease from the tubes’ surface.

A clean surface helps to achieve optimal results and makes better conductivity possible during welding. It also prevents impurities from entering the weld pool.

Right Welding Process

Tube welders can use different welding processes for different applications. The considerable factors include material type, weld strength and production speed when choosing between welding methods. Some common processes include:

- TIG Welding offers accurate, clean welds for thinner tubes.

- MIG welding is faster and good for thicker materials but may produce slightly less clean results.

- Resistance Welding is efficient for high-volume tube welding but requires proper machine calibration for consistent results.

Monitoring Heat and Speed

Monitoring the heat and speed of the machine during the welding process is important. The welding tube requires a controlled welding speed and heat. Excessive heat would be harmful to the material as it causes burns through or wrap, while too little heat results in weak welds. Tube welders should adjust machine settings in a way that maintains a stable temperature throughout the process.

The BOBO tube welding machines come with adjustable welding parameters and PLC control systems. Their machines allow welders to fine-tune settings for better weld quality. In the same way, the right welding speed is of equal importance to prevent defects such as undercuts or incomplete fusion.

Shielding Gas

Welders can use shielding gas to protect the weld pools from contaminants like nitrogen and oxygen. It is mainly useful in processes like TIG and MIG welding. Picking the right type and amount of shielding gas improves the quality of the weld. It makes the tubes free from contaminants and results in a clean and durable joint. Common gases include:

- Argon is best used by all welders for aluminum and stainless steel.

- Helium is used for thicker materials or to increase welding speed.

Weld Inspection

It is important for a tube welder to inspect the weld properly after the completion of welding tubes. Proper checking helps in figuring out if the resultant weld meets the required standards. Common issues that should not go unnoticed are check porosity, cracking, and inconsistent bead formation. High-quality tube welding machines equipped welders with the tools needed to check the welds’ integrity. Advanced techniques, like ultrasonic testing or visual inspection, are helpful for critical applications.

Safety Measures:

Due to harmful fumes and high-temperature risk, safety measures should be the first priority of welders during welding. It’s important to wear proper personal protective equipment or PPE, like.

- The welding helmet protects the eyes from UV radiation.

- Gloves shield hands from heat and sparks.

- An apron protects clothing and skin from hot sparks.

- A ventilation or fume extraction system helps to remove toxic fumes from the workspace.

BOBO always focuses on safety in its tube welding machines and their Wire On Tube Condenser Welding Machine features network voltage floating compensation. It maintains consistent welding performance even when the network voltage fluctuates. It is important to create a safe environment, along with following welding best practices to prevent accidents and achieve high-quality results.

Conclusion

A tube welder is a skilled person but still needs a proper understanding of the materials and tools to get accurate results. Settings, material selection, tube alignment, and cleaning processes, all things are important to achieve the best welds. The tube welding machines provide excellent control over all these factors and offer consistent and high-quality results. Welders can achieve durable results and improvement in their performance by following these tips and utilizing the right welding machines.

Want to Know More About Our Products?

View All Products Now