What Is Finned Tube Heat Exchanger? Types And Their Related Processing Machines

Finned tube heat exchangers are heat exchangers with finned tubes that efficiently perform heat transfer between two fluids, air and liquid. The fins on finned tube coils increase heat transfer by increasing the surface area of the tube.

Finned heat exchangers are part of almost every industry that needs an efficient means of heat transfer between two fluids: air and liquid. In a fin heat exchanger, fins are added on the outer side of the tube to increase its surface area, which allows quick and efficient heat transfer between fluids. This overall positively affects the efficiency of the system. Let’s discuss some types of finned tubes and their benefits with some related processing machines in detail here.

What Is Finned Tube Heat Exchanger

Finned tube heat exchangers are devices that use air to heat or cool other fluids like water, oil, and gas by transferring heat. They are even used to capture and recover waste heat efficiently in various industries. You will see its application in

- oil & gas industry

- power generation industry

- marine industry

- HVAC&R

There are other heat exchangers, but the fin tube ones are preferred when air is the basic medium to cool or heat the other fluid efficiently, especially when the other fluid is limited or of poor quality water.

In its working process, the heat exchanger allows heat exchange between two fluids: a Thermal fluid (like a liquid with some viscosity) that transports heat well and a less efficient fluid (like air or gas, which has little density).

As air is outside the tube, fins and looped wires are also added to the outer side to enhance the surface area of the tube to improve its thermal efficiency.

Fins come in various sizes (high-fin or low-fin) and can either be attached to the tube surface or formed as part of the tube itself. Depending on the application, finned tubes are made from different materials and designs to suit various environments.

Finned Tube Heat Exchanger Working Principle

The fin tube heat exchanger working principle is based on increasing the surface area of a tube which is available for heat transfer between a fluid flowing inside the tube and a fluid (usually air) flowing outside the tube. Here’s how Fintube heat exchanger operates.

- Two fluids flow, one inside the tube and the other on the outside, over the fins and tubes.

- Heat moves from inside flowing fluid to fins and then to fluid flowing outside the tubes and vice versa.

- Fins increase the surface area of the tubes for efficient heat transfer.

Finned Tube Heat Exchangers Applications

Heat exchanger fins are versatile and available to use for various industries like:

- Home Appliance

- Commercial

- Industry

- 3C Electronic

- Automobile

- Aerospace

- Military

Finned Tube Heat Exchangers Advantages

Fin tubes heat exchangers have many advantages, that’s why they are widely used in almost all industries.

- Fins increase the surface area of the tube in a heat exchanger, which enhances the heat transfer efficiency.

- They are compact in design and efficient in providing high heat transfer rates. Their small space makes them ideal for various industrial installations as they take less space.

- Various types and their combinations are available. By handling various fluids efficiently, finned tube heat exchangers are best to use in a wide range of applications.

- Their strong construction and material make them durable and resistant to mechanical and thermal stresses.

Types Of Finned Tube Heat Exchangers

1: Helical/Spiral Finned Tube Heat Exchangers

Helical or spiral finned tube heat exchangers have helical or spiral-shaped fins to the outside of the tube. Both increase the surface area of the tube to make it efficient enough to transfer heat from one fluid or gas to another. Spiral and helical fins are best to use in the following industries:

- power generation

- chemical processing

- petrochemical refining

- HVAC

- boilers

- condensers

- air coolers

To make wound finned tubes, the manufacturers wind a fin material strip around the tube and use some mechanical binding to secure it with the tube. The heat exchangers using wound finned tubes are cost-efficient and suitable for various industries like

- Air preheater

- power plants

- Automotive radiators

2: L-Finned Tube Heat Exchangers

L-finned are one of the common types of finned tubes used in heat exchangers. It’s called L-footed finned because of the shape it makes with the tube, which looks like the letter L in the cross-section view. This shape is achieved by tightly wrapping a strip of metal around the base tube in a helical pattern.

This design offers maximum surface area for heat exchange, and the process of tension-forming the fin makes sure of a strong and consistent bond between the fin and the tube which allows more efficient heat transfer between the two.

Moreover, this shape also enhances the corrosion resistance of the tube. Aluminum or copper is used in the formation of L-footed aluminum finned tubes and finned copper tubing, as both are ductile; they can withstand the compression around the fin’s base without breaking or deforming.

Moreover, these metals’ flexibility allows them to stretch on the outside of the tube during the installation process. The ‘L’ fin is effective in environments with temperatures ranging from 150 to 170°C, making it suitable for a wide range of heat exchanger applications. The L-footed finned tubes are best for

- Chemical processing

- Air conditioning systems

- Industrial boilers

3: LL-Finned Tube Heat Exchangers

From temperature range and material to manufacturing process, the LL-finned tubes are similar to L-footed finned tubes. When it comes to design, it has overlapping feet which entirely enclose the base of the tube.

This design helps the LL-finned tube to offer excellent corrosion resistance to the heat exchanger. Moreover, its interlocking fins are wound together in such a way that it prevents separation and movement.

In this way, it protects the whole tube and makes heat exchange efficient. The LL-Finned tubes are best to use in applications where corrosion can occur often.

4: KL-Finned Tube Heat Exchangers

Knurled finned tubes, the short form is KL-Finned tube. The shape is achieved by wrapping the fin around the tube with the foot rolled into the pre-knurled tube’s outer surface and secured at both ends.

First, a strip of metal is used to manufacture a fin, which is given an L-shaped foot by a machine and curled by rolling it into a taper. With the help of a rotating tool, the surface of the tube is knurled so that the fin’s foot is knurled into the base of the tube to make a strong bond. Such tight KL-finned tube bonds are best to optimize thermal transfer.

5: ‘G’ Embedded Finned Tube Heat Exchangers

These are carbon steel fins that are wound into helical grooves on the tube surface. The ‘G’ fins are highly durable and can tolerate up to 400°C temperature. The only limitation is the required 1.65mm wall thickness, which is important for accommodating the grooves.

The other materials used for G type fins are aluminum or copper for better thermal conductivity, but their temperature tolerance is lower than carbon steel. Their material offers better thermal conductivity than carbon steel and the design allows excellent thermal contact and thermal cycling resistance. These G-type fins are best used in

- Refrigeration units

- Heat recovery systems

- Industrial dryers

6: Extruded Finned Tube Heat Exchangers

Extruded finned heat exchangers use bi-metallic tubes with an aluminum outer layer and an inner tube of various materials. Fins are formed by rolling material from the outer tube, creating a strong bond for excellent heat transfer and corrosion protection. These exchangers, with tightly bonded rectangular fins, are ideal for high-heat applications:

- HVAC applications

- air compressors

- oil and gas industries

- power generation

7: Integral Finned Tube Heat Exchangers

The integral finned tube heat exchangers have integral fins that are directly attached to the tube material or formed as part of it. Roll forming and extrusion by extruding machines are two processes used in their manufacturing. The integral finned tube has several uses in various industries and products where efficient heat exchange is essential for the system’s performance, like

- air coolers

- industrial drying system

- air preheaters

Related Processing Machines

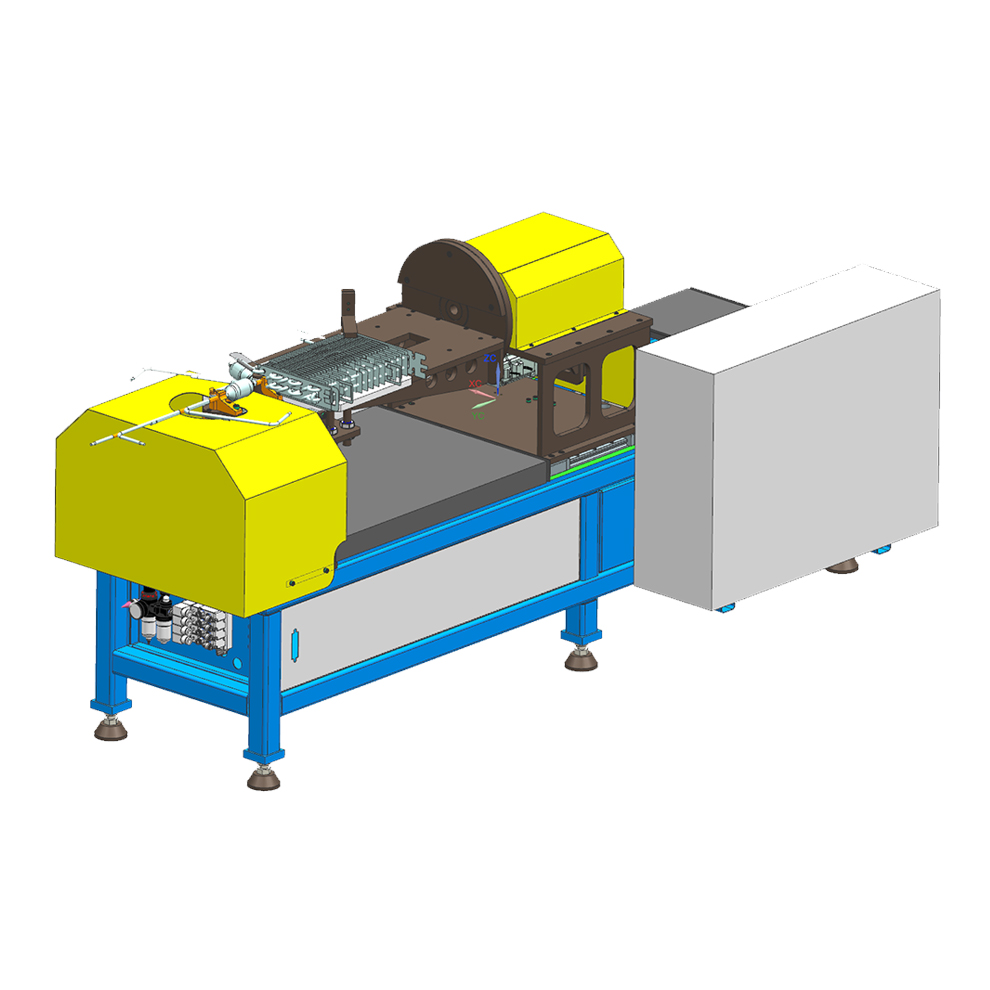

When it comes to manufacturing fin and tube heat exchangers, various related processing machines are required to cut the fin and give it proper shape or bending. Here we discuss a few of them here.

- Straightening & Cutting Machine: These machines are almost always needed for preparing the base tubes to the correct length and sometimes the fin material. It is also helpful in straightening the tube and fins before further processing the manufacturing of heat exchanger finned tubes.

- Tube & Pipe Bending Machine: If you want to bend the fin tubes into a specific shape like U-bends or coils, use tube and pipe bending machines.

- Tube & Pipe End Forming Machine: These are most often needed machines for preparing the ends of the tubes to make them connect to headers, manifolds, or other components. This machine is also helpful in expanding, reducing, flaring, or threading the tube ends.

- Welding & Brazing Machine: This machine is not widely required, but for attaching fins to the tube in L-footed fins or to join sections of the heat exchanger.

- Fin Making Machine: This is the most crucial machine for most types of finned tubes except extruded fins. Its main function is to form the fins themselves.

- Fin Tube Machine: This is the most crucial machine and is required mostly for all types of tube fin heat exchangers, as its function is to assemble the fins onto the tube.

Here is a comprehensive table that helps you understand which machine is required for which type of finned tubing.

| Fin Type | Straightening & Cutting | Bending | End Forming | Welding/Brazing | Fin Making | Fin Tube Machine |

| L-Finned | Yes | Conditionally | Often | Yes (sometimes) | Yes (for fin strip) | Yes (for wrapping) |

| LL-Finned | Yes | Conditionally | Often | Yes (sometimes) | Yes (for fin strip) | Yes (for wrapping) |

| KL-Finned | Yes | Conditionally | Often | Yes (sometimes) | Yes (for fin strip) | Yes (for wrapping) |

| Helical/Spiral Finned | Yes | Conditionally | Often | Yes (sometimes) | Yes (for fin material) | Yes (for wrapping) |

| Extruded Finned | Yes | Conditionally | Often | No | No (formed during extrusion) | Yes (Extrusion Machine) |

| G Embedded Finned | Yes | Conditionally | Often | No | Yes (for fin strip) | Yes (Embedding Machine) |

Conclusion

Heat exchangers efficiently transfer the heat from one fluid to another. In finned tube heat exchangers, the fins are added to the tubes to further increase the surface area of the tubes and allow more quick and efficient transferring of heat. They offer a lot of benefits, that is why they are widely used in all industries for their efficient working. As they are available in various shapes and types, you can get the required one by using processing machines which cut and bend them according to your industry needs.

Want to Know More About Our Products?

View All Products Now