What Is Mandrel Tube Bending?

Mandrel tube bending is a precision process that shapes tubes and pipes without causing wrinkles, flattening, or cracks. It uses an internal tool called a mandrel to support the tube’s inner walls during bending, keeping its shape and strength intact. This method delivers smooth, accurate bends that meet tight tolerances—essential in industries like automotive, aerospace, oil and gas, and construction where performance and safety depend on exact dimensions.

This article explains what mandrel tube bending is, how it works, why using a mandrel matters, and how to choose the correct mandrel for your project. By understanding these fundamentals, anyone involved in fabrication or manufacturing can make informed decisions that improve precision and efficiency.

What Is Mandrel Tube Bending?

Mandrel tube bending is a rotary draw bending process that uses a mandrel, a metal rod or tool inserted inside the tube during bending. The mandrel supports the inner wall, controlling how the material stretches and compresses. This helps maintain the roundness of the tube and prevents internal damage.

Mandrel tube bending relies on an internal support tool to shape tubes precisely while preventing collapse, wrinkling, or deformation. It ensures smooth, accurate bends in metal tubes and pipes used for applications that require high strength and uniform dimensions.

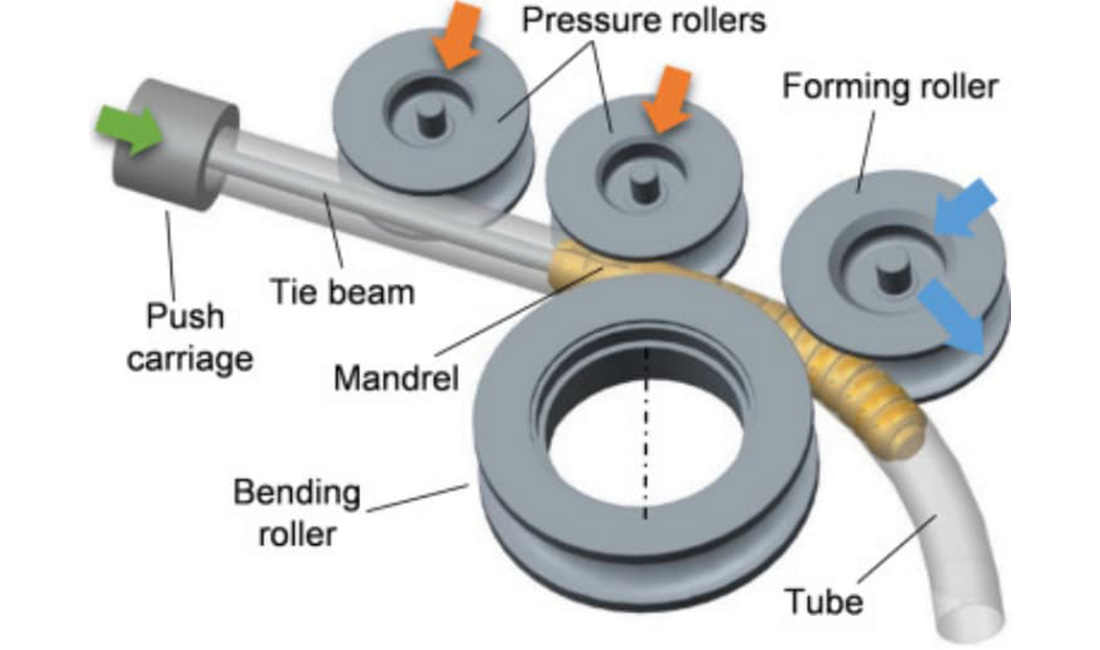

In a typical setup, the tube is clamped against a bending die while the mandrel stays inside. The bending die rotates, pulling the tube around its radius to form a controlled bend. This method is especially useful for thin-walled tubing and tight-radius bends, where precision is critical.

Manufacturers often use CNC (Computer Numerical Control) machines for mandrel bending to achieve consistent and repeatable results. The process is common in industries such as automotive, aerospace, oil and gas, and construction, where accuracy and tube integrity are vital.

Types of Tube Bending Mandrels

Mandrels come in different designs suited for various materials and bend requirements. Common types include:

| Mandrel Type | Description | Best For |

| Plug Mandrel | A solid rod that provides moderate internal support. | Thicker tubes require minimal deformation control. |

| Ball Mandrel | Contains one or several linked steel balls for flexibility. | Thin-walled tubes and tight bending radii. |

| Formed or Sand Mandrel | Filled or shaped versions used for unique material needs. | Specialized or delicate applications. |

Choosing the right mandrel depends on tube diameter, wall thickness, and bend radius. A properly matched mandrel reduces stress, prevents wrinkling, and improves the final surface finish. Proper placement inside the tube is also essential to ensure consistent performance and durability of the bend.

Importance of Using a Mandrel in Tube Bending

Key benefits of using a mandrel include:

- Maintains accurate bend radius and consistent cross-section

- Reduces ovality and surface defects

- Allows tighter bends in thin-walled tubing

- Supports thicker or larger tube diameters when combined with correct tooling

A mandrel is a metal insert placed inside a tube during bending to support its inner wall. It helps maintain shape and strength, especially for thin-walled tubes that bend more easily under pressure. By reducing distortion, the mandrel ensures that the tube remains round and smooth after forming.

Without proper internal support, tubes often wrinkle, flatten, or collapse. This problem becomes more noticeable when working with small bend radii or thin materials. The mandrel counteracts these forces by providing internal resistance as the tube is drawn around the die.

How Does a Mandrel Tube Bending Work?

The process of mandrel tube bending relies on careful machine setup, correct mandrel type, and accurate coordination between pressure, clamping, and rotation. It uses an internal support tool to maintain the tube’s shape while forming it to a precise bend angle. Preparation and Setup

The bending process begins with preparing the tube and equipment. The operator checks tube dimensions, wall thickness, and material properties to ensure compatibility with the bending machine. Each factor affects how the tube responds to force and how tight the bend radius can be.

Next, the tube is cut to length and cleaned to remove any debris or coatings that could interfere with bending. The bending machine is then calibrated. Key parameters include bend angle, clamping force, and rotation speed. These settings help the machine apply uniform pressure throughout the process.

A short test bend is often performed before production. This fine-tunes the setup, confirms the correct die size, and reduces the risk of wrinkles or collapse. Consistent preparation ensures that every tube bend is accurate and repeatable.

Mandrel Selection and Placement

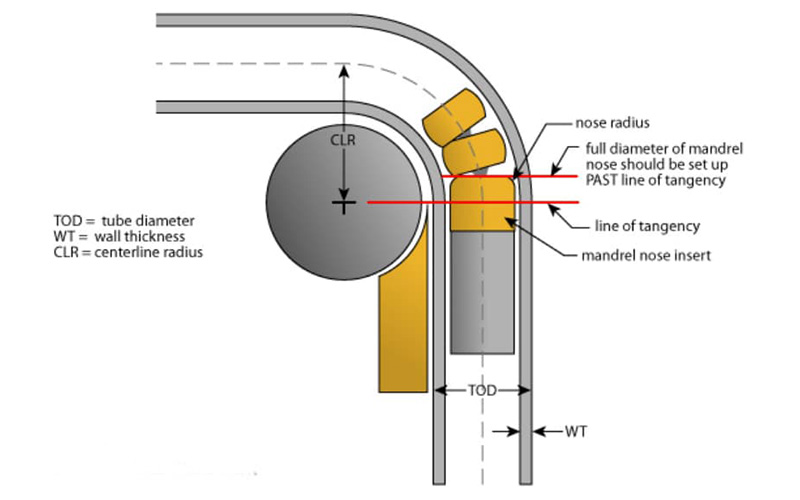

A mandrel is a metal rod or assembly inserted inside the tube to support it during bending. It prevents distortion or flattening as the tube curves around the die. Choosing the correct mandrel depends on tube material, wall thickness, and bend radius.

Positioning matters. The mandrel’s nose should sit slightly past the tangent point where bending starts. If placed too far in or out, the tube may wrinkle or lose shape. Operators verify alignment before bending to maintain consistent wall thickness.

Executing the Bend

Once set up, the tube clamps in the machine while the mandrel stays inside to provide internal backing. The bending die rotates to create the desired bend angle, while pressure and clamp dies hold the tube steady.

The tube stretches on the outer side and compresses on the inner side. The mandrel limits both movements, preventing collapse and thinning. Operators monitor for springback—when the metal relaxes slightly after release—and adjust settings as needed.

After the bend is complete, the mandrel retracts smoothly. The finished tube is inspected for accuracy, surface quality, and dimensional tolerance before moving to the next operation.

How to Choose a Right Tube Bending Mandrel?

A tube bending mandrel is an internal support tool placed inside a tube during bending to maintain its shape and prevent wrinkling or collapse. Choosing the correct mandrel depends on the tube’s material, wall thickness, and required bend radius.

Key factors to consider for choosing a right tube bending mandrel include:

- Tube material: Softer metals, like aluminum or copper, often need more internal support than harder metals such as steel.

- Wall thickness: Thin-walled tubes require flexible mandrels, while thicker tubes can use simpler types.

- Bend radius: Tighter bends usually need more precise mandrels to maintain the tube’s cross-section.

- Production method: Automated or CNC bending machines may require custom mandrels for consistent results.

Proper mandrel placement inside the tube is also essential. If the mandrel is set too deep or too shallow, it can cause uneven bends or wrinkling. Operators should also match the mandrel’s diameter closely to the tube’s inner diameter for accurate support during the bend.

Frequently Asked Questions

How does mandrel bending differ from traditional pipe bending techniques?

Mandrel bending uses a solid or flexible insert, called a mandrel, inside the tube during bending to prevent collapse and wrinkling.

Traditional pipe bending methods, such as crush or press bending, rely on external force alone. These methods can flatten the tube’s cross-section or cause irregularities, especially in thin-walled tubing.

By supporting the internal wall of the tube, mandrel bending keeps the pipe round and uniform, making it ideal for high-performance applications like automotive exhaust systems and aerospace components.

What types of materials can be bent using a mandrel bending machine?

Mandrel bending machines can handle a wide range of metals and alloys. Common choices include steel, stainless steel, aluminum, copper, and titanium.

The hardness of the mandrel is selected based on the tubing material. Softer metals often use harder mandrels made from steel or chrome, while harder alloys may require softer mandrels made from aluminum or bronze to avoid scratching the interior surface.

This flexibility allows manufacturers to maintain accurate dimensions and clean finishes across different material types and thicknesses.

Can mandrel bending ensure the integrity of a pipe during the bend test?

Yes. Mandrel bending preserves the internal structure and strength of the pipe during bending, which helps it pass standard bend tests.

The internal support limits thinning on the outer radius and compression on the inner radius. This control reduces the chance of cracks, creases, or shape distortion.

As a result, pipes bent using mandrel equipment typically maintain their full flow capacity, meet inspection standards, and perform reliably under pressure or vibration.

Want to Know More About Our Products?

View All Products Now