Finned tube Machinery

Simple Partner Steps

Communication

Order Confirm >>Production

Delivery >>On-Site Set up

Operation >>Finned tube Machinery

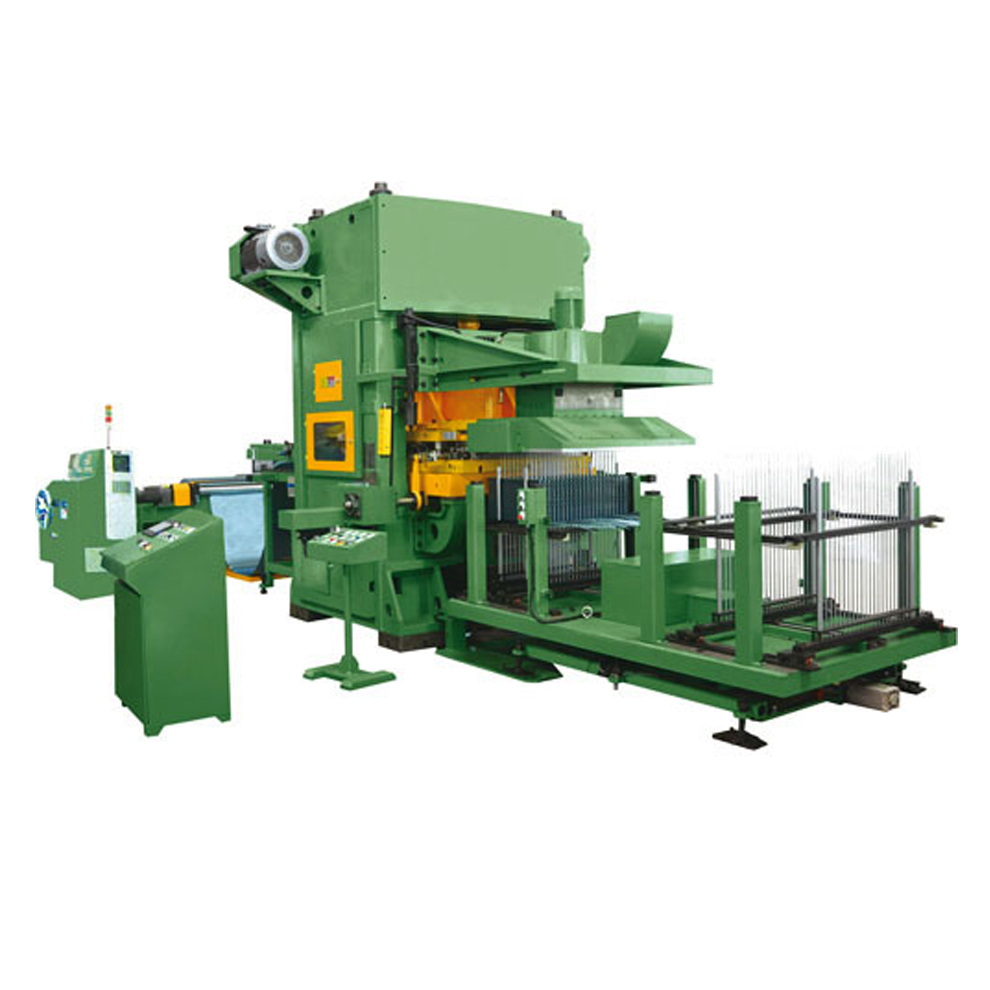

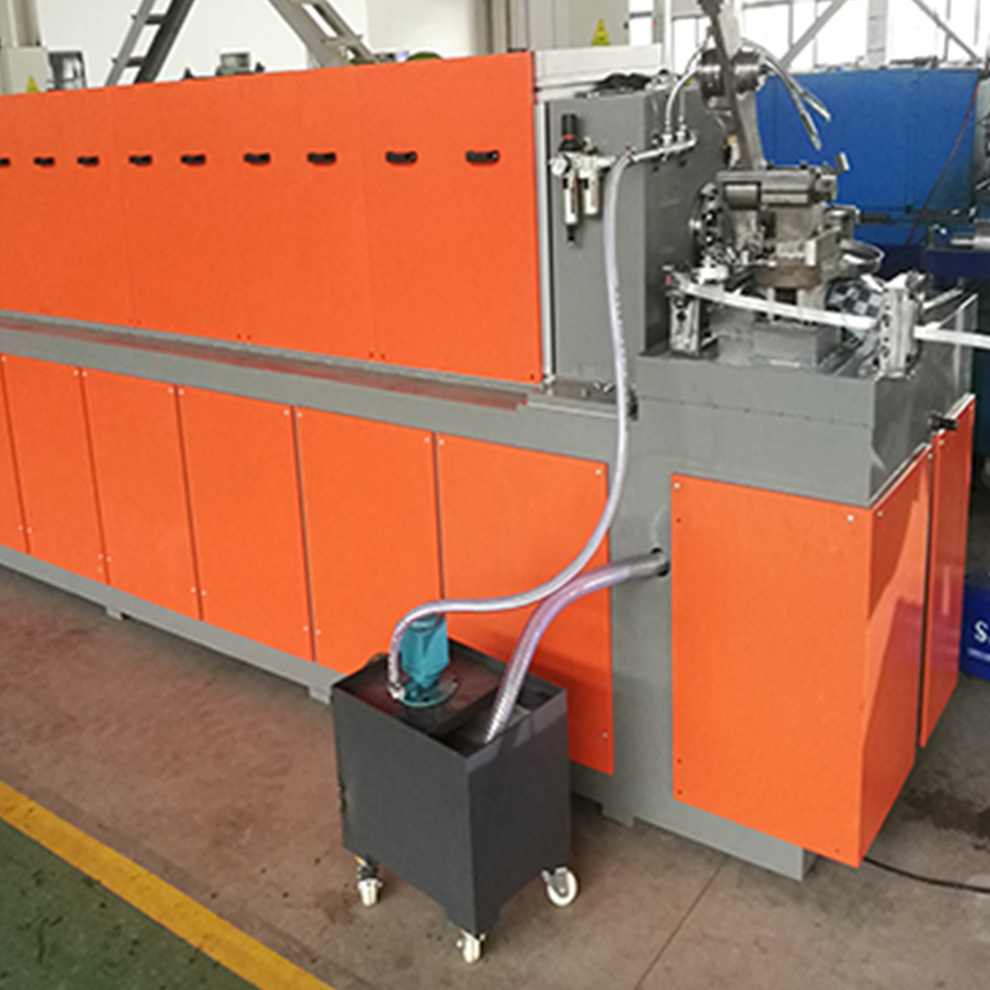

Finned tube Machinery

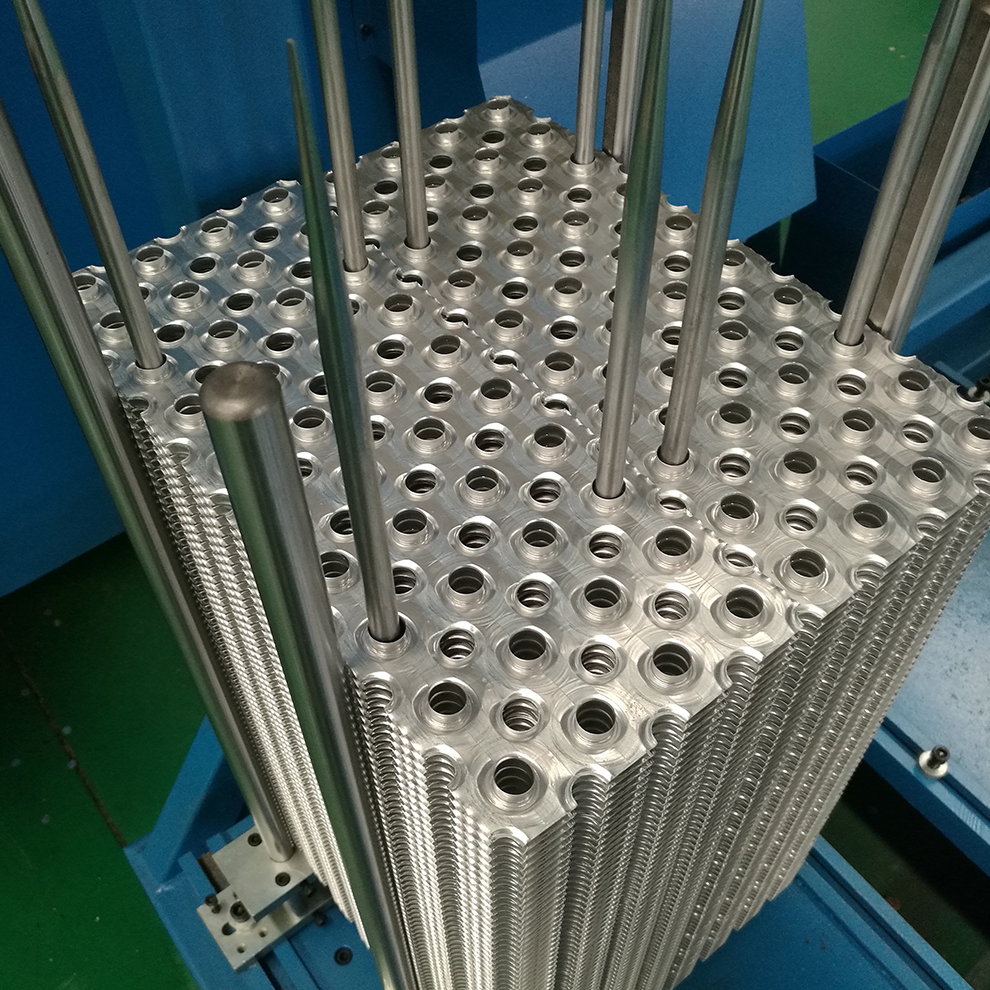

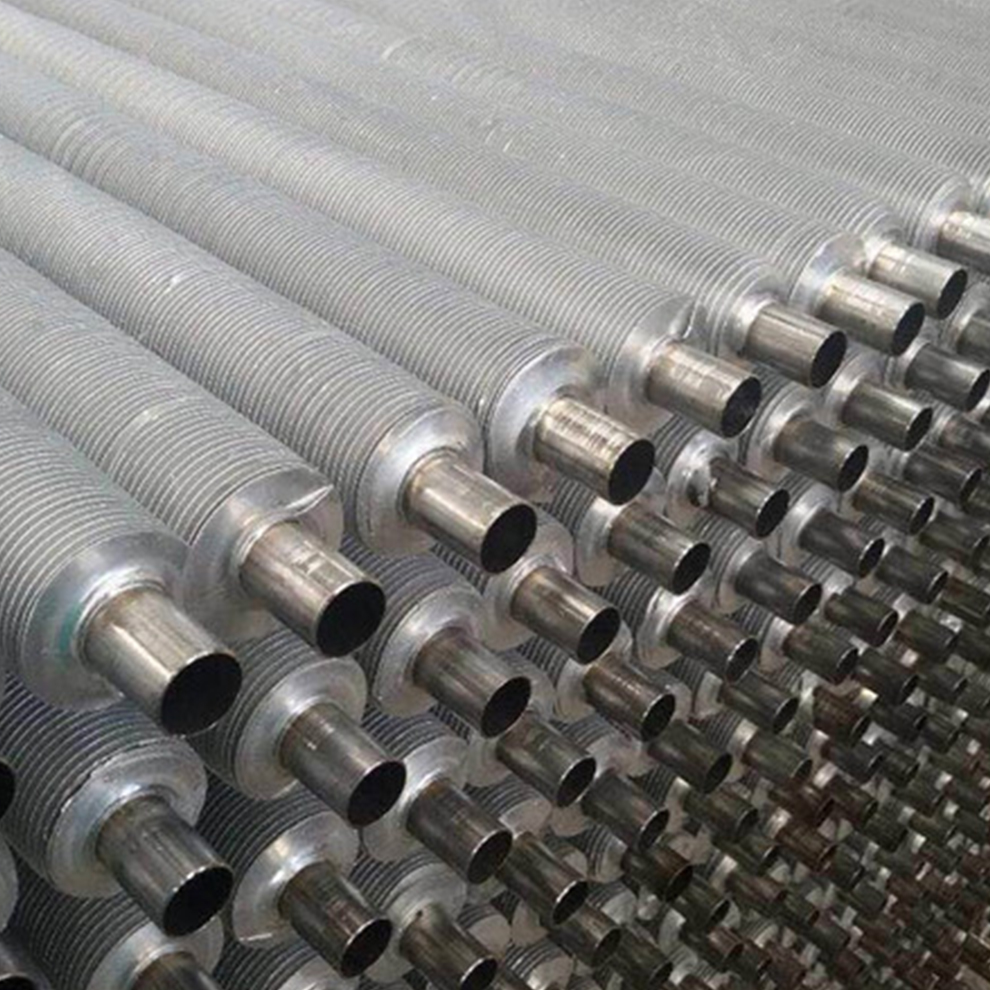

BoBo finned tube processing machines can reach ±0.01mm precision, offer you accurate heat exchanger machinery experience. Our equipment are suitable for mass production with large capacity.

Finned Tube Machinery for Different Tube Types

Finned Tube Machinery for Different Tubing Crafts

Custom Services & Tubing Machine Case Study

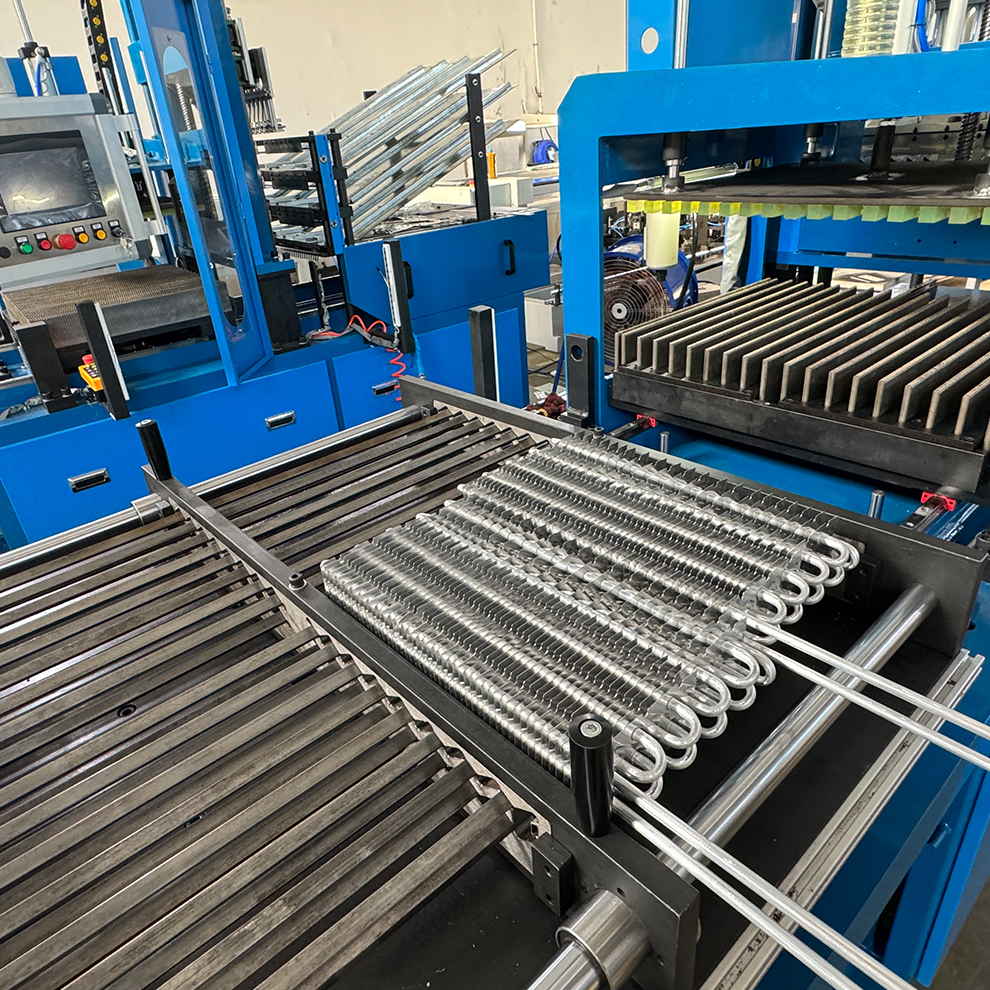

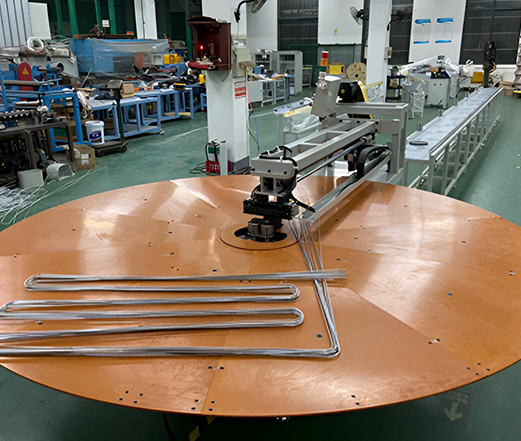

CNC Coil Tube Straightening, Cutting, Tube End Forming, Left&right Bending Machine

This multi-station pipe end forming (or dot), high-end automated combined equipment for automatic bending forming left and right sharing.

It is mainly used for automatic chipless opening of copper, aluminum, and steel coil pipe fittings for air conditioners, water heaters, aircraft, automobiles, etc.

Combined Craft Functions:

Precisions

OEM&ODM Services

3 Level Set up Services

12 Months Waranty

See Our Successful Case with B/S/H

Tubing Machine Applications

Home Appliance Heat Exchange Tubes Processing Solutions

In home a ppliance heat exchanger market, finned-tube radiators are often used in HAVCs, household radiators or floor heating systems, refrigerators, household dryers, ovens, electric heaters, household dryers or clothes drying systems.

Commerial Heat Exchange Tubes Processing Solutions

Bobo Heat tubing machines are widely used by manufacturers of commercial air conditioners, chillers, rooftop units, heat pump systems, and commercial water heating products, helping them increase production speed, reduce labor costs, and ensure consistent quality in mass production.

Industry Heat Exchange Tubes Processing Solutions

In industrial production, it is very important to maintain a suitable temperature environment(e.g. industrial servers, laser coolers and furnace temperature curve control). Finned tube radiators play a key role in all kinds of factory buildings.

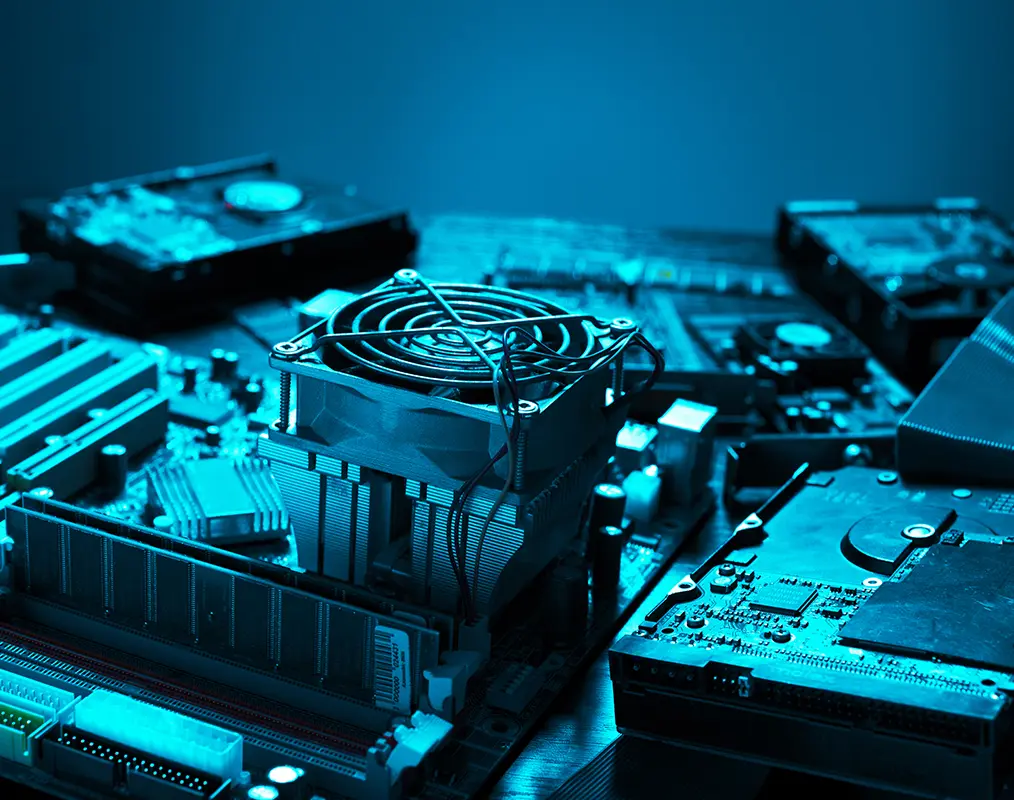

Electronic Heat Sink Machinery Solustions

Heat sink processing machines are used in the 3C electonic industries of computer GPU/CPU, phone and projectors manufacturing. With the electronic equipment developing, finned tube radiator has become the key to ensure normal operation of equipment.

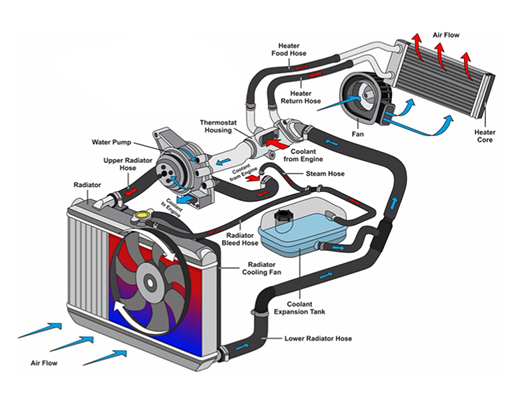

Automobile Tube Processing Solusions

Themachine excels in air conditioning refrigeration & heat dissipation, and brake hose systems. It delivers stable cooling, reliable pressure control, boosting the systems’ efficiency and safety significantly.

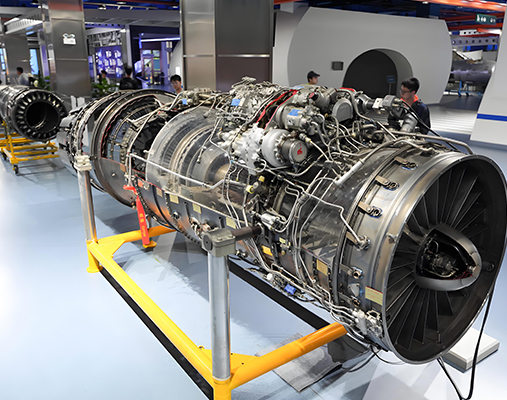

Aerospace Tube Processing Solusions

The machine is specialized for pipeline applications in aerospace launchers. It guarantees precise pipeline connection and stable fluid transfer, enhancing the reliability of critical launch system operations.

Military Cooler Machinery Solutions

In command and control centers, military bases, and other facilities, finned heat pipes are used to maintain a suitable temperature and humidity environment.

Contact Us Now

Certifications

FAQs

Yes. BoBo Machine offers Tube End Former that uses servo motors and CNC control system to ensure length accuracy and precision, even under continuous day-and-night shift operations.

Yes, the cooperation support will not end after the warranty period. But the price of components for replacement should be at cost price,while in the warranty period this price is free, in addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP

Yes, we could provide private label or white label services, Customization services are available according to your demands.

Yes. We provide on-site set up services.Install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solutions.

Finned tube machinery can be applied in the producing line of HVAC (for evaporator and condenser coils), automotive (radiator and oil cooler lines), home appliances (freezers, water dispensers), and renewable energy (solar thermal collectors, fuel cells).