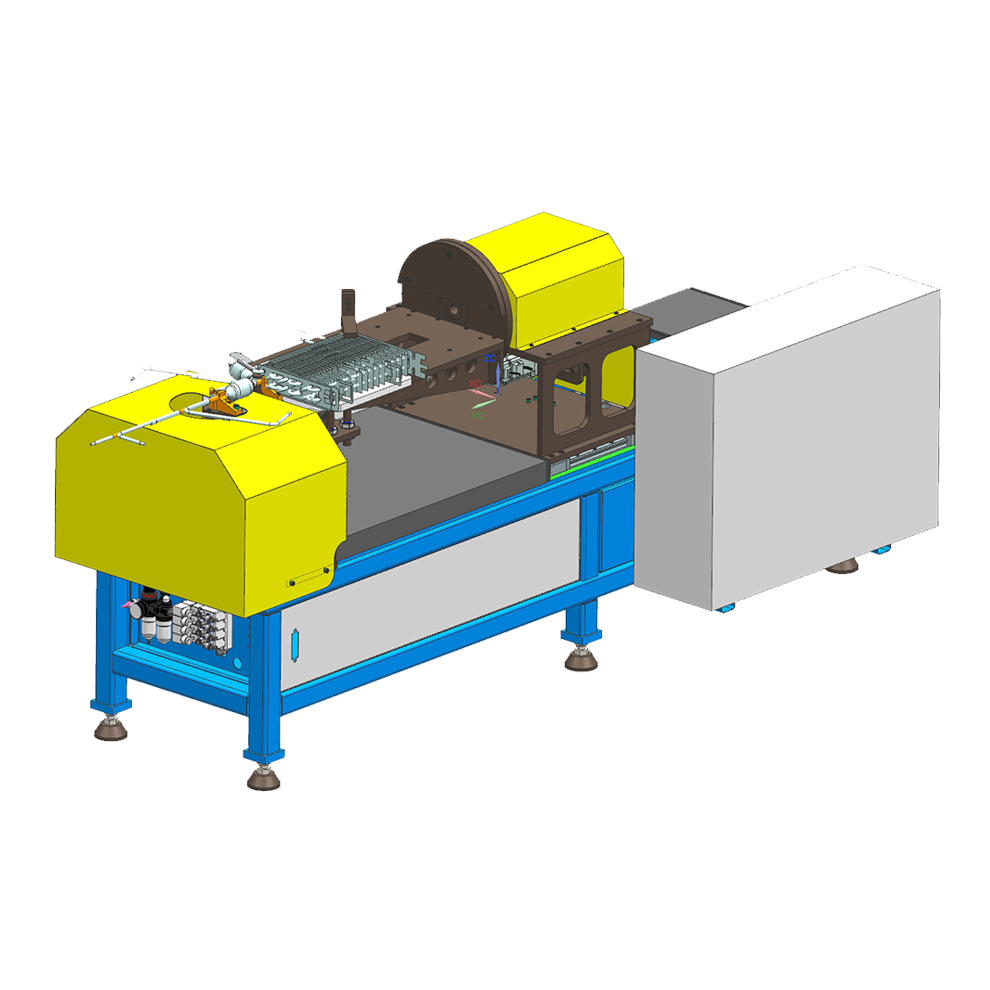

Fin Stamping Press Machine P-300/450

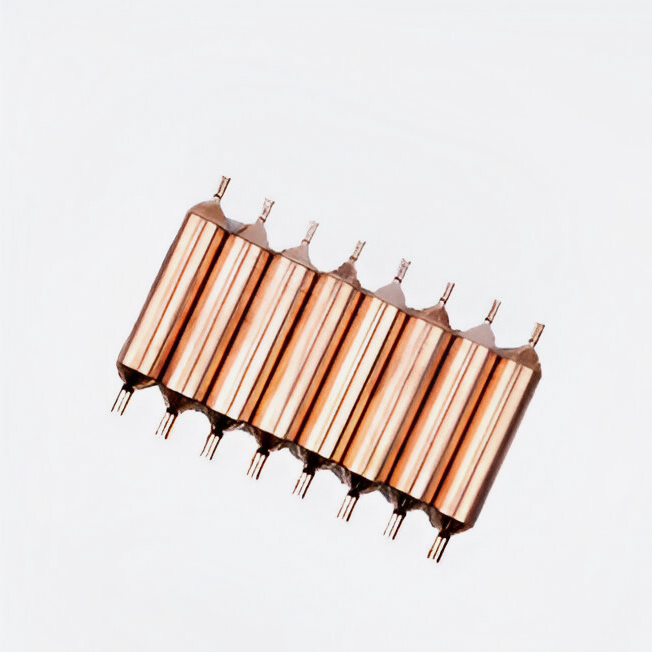

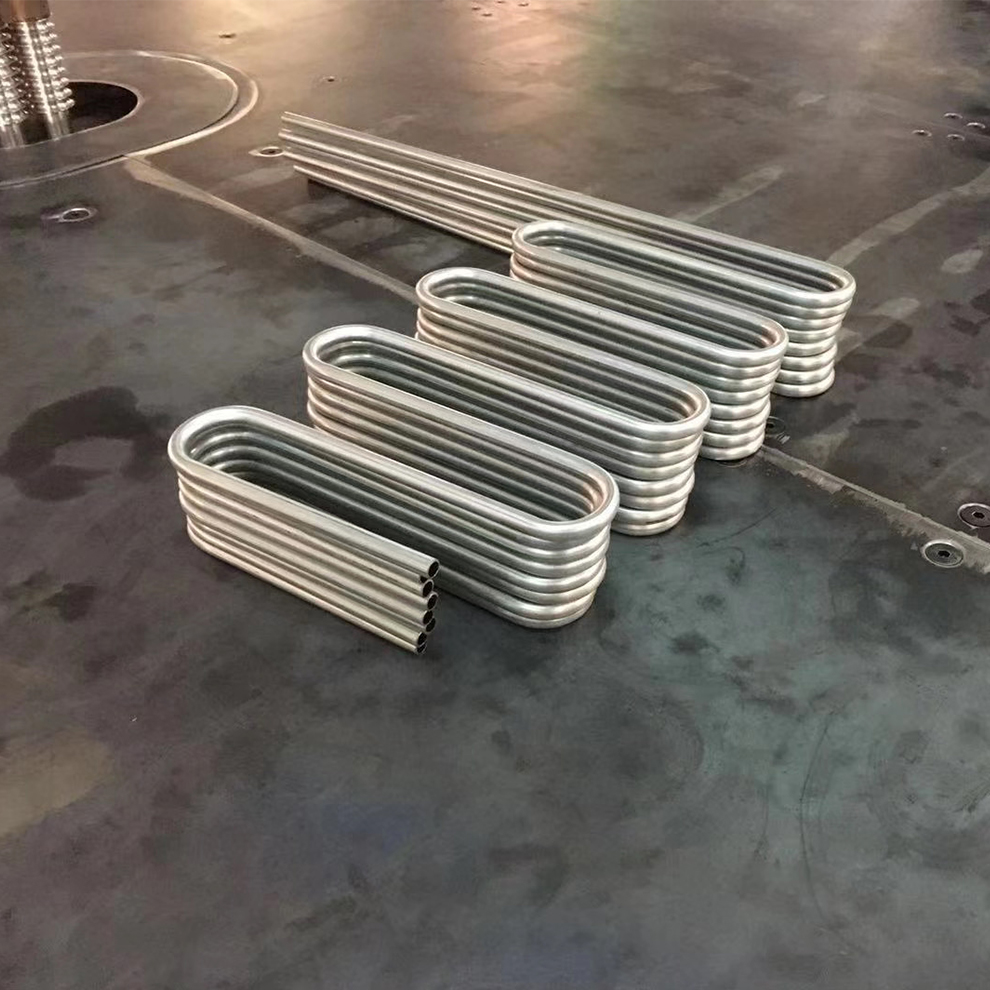

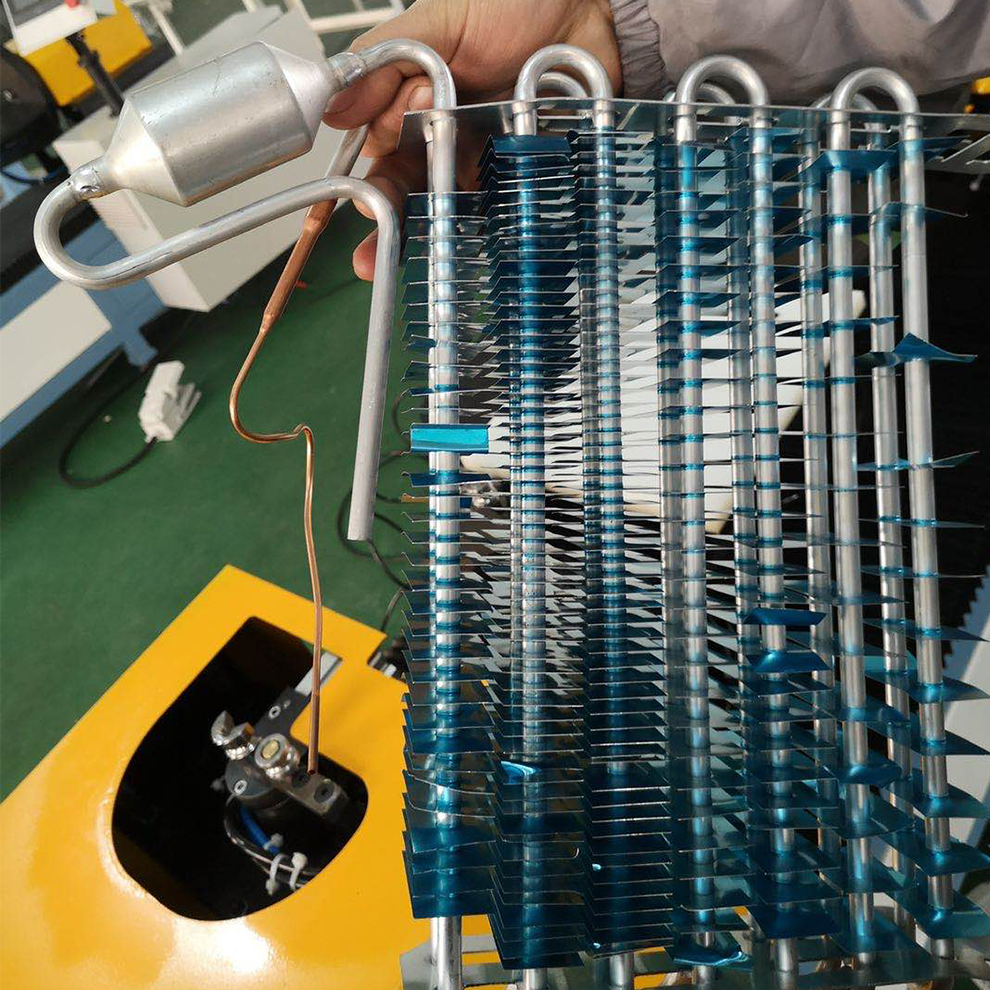

The fin forming machine is a special processing equipment for processingheattransfer fins, a key component of heat exchangers. Compact heat exchangers made up of such heat transfer fins have been used in a wide range of applications in the automotive, marine, air conditioning, compressor, construction machinery,miningmachinery, aerospace, military and hydraulic oil cooling industries.

Parameter

Parameter | Data | |

|---|---|---|

| Control Decoiller speed | 0-5000mm | |

| Decoiller running rate | 0-20 | |

| Times/Min Coil inner diameter | 150mm+/-10mm Coil Max | |

| Diameter | 1400mm | |

| Coil max width | 450mm | |

| Motor power | 0.75 KW | |

| Loading weight | 1000KG | |

| Weight | 120KG | |

| Dimension | 1050*650*1100mm | |

Parameter | Data | |

|---|---|---|

| Servo cutter width | 10-300mm | |

| Cutting rate | 60 times/Min | |

| Cutting height | 0-14mm | |

| Air pressure | 0.5-0.8mm | |

| Air pressure | 0.4-0.6Mpa | |

| Weight | 110Kg | |

| PLC | Mitsubishi | |

| Touch screen | Delta | |

Features

Zero-Loss Force Transmission

Adaptive Die Intelligence

Eco-Performance Optimization

Failure-Proof Production Guardrails

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.