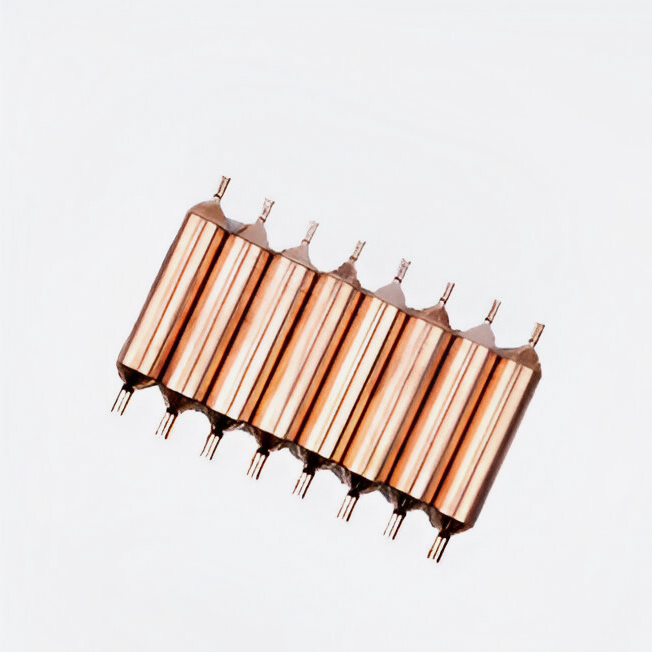

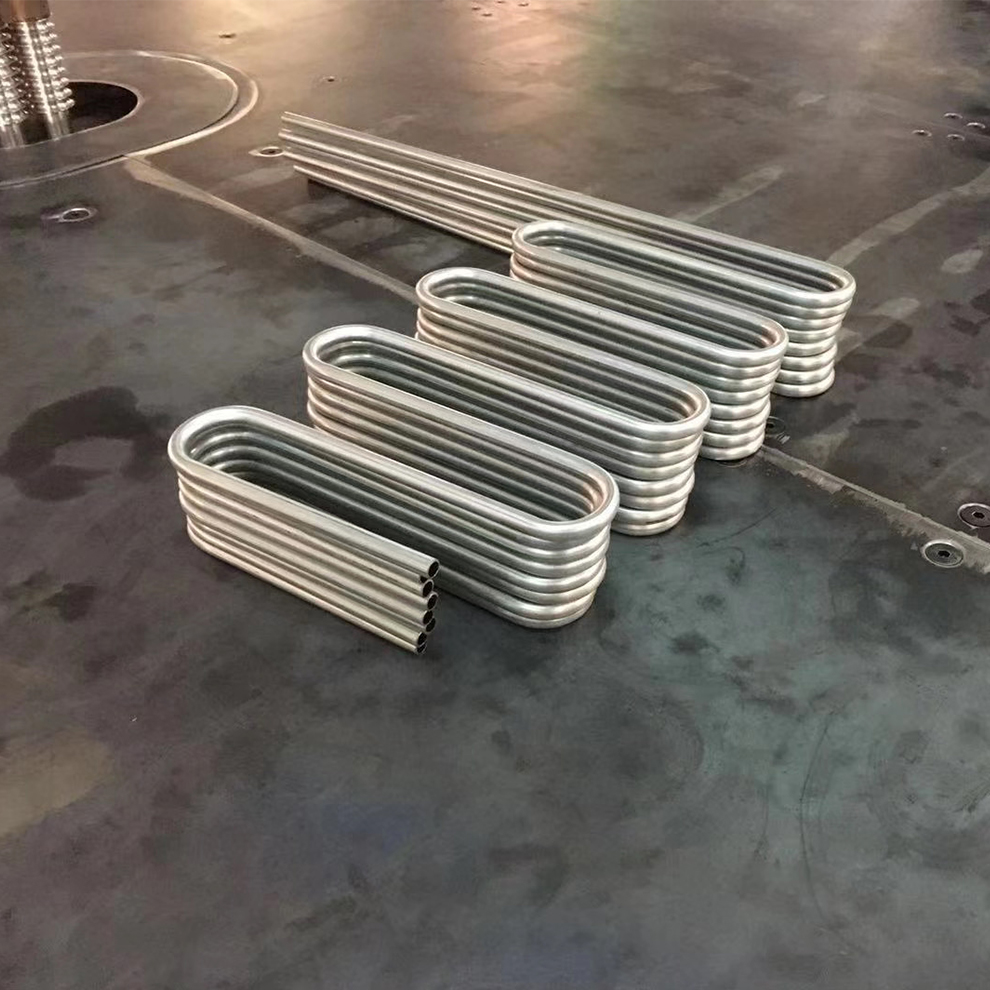

Wire On Tube Condenser Welding Machine

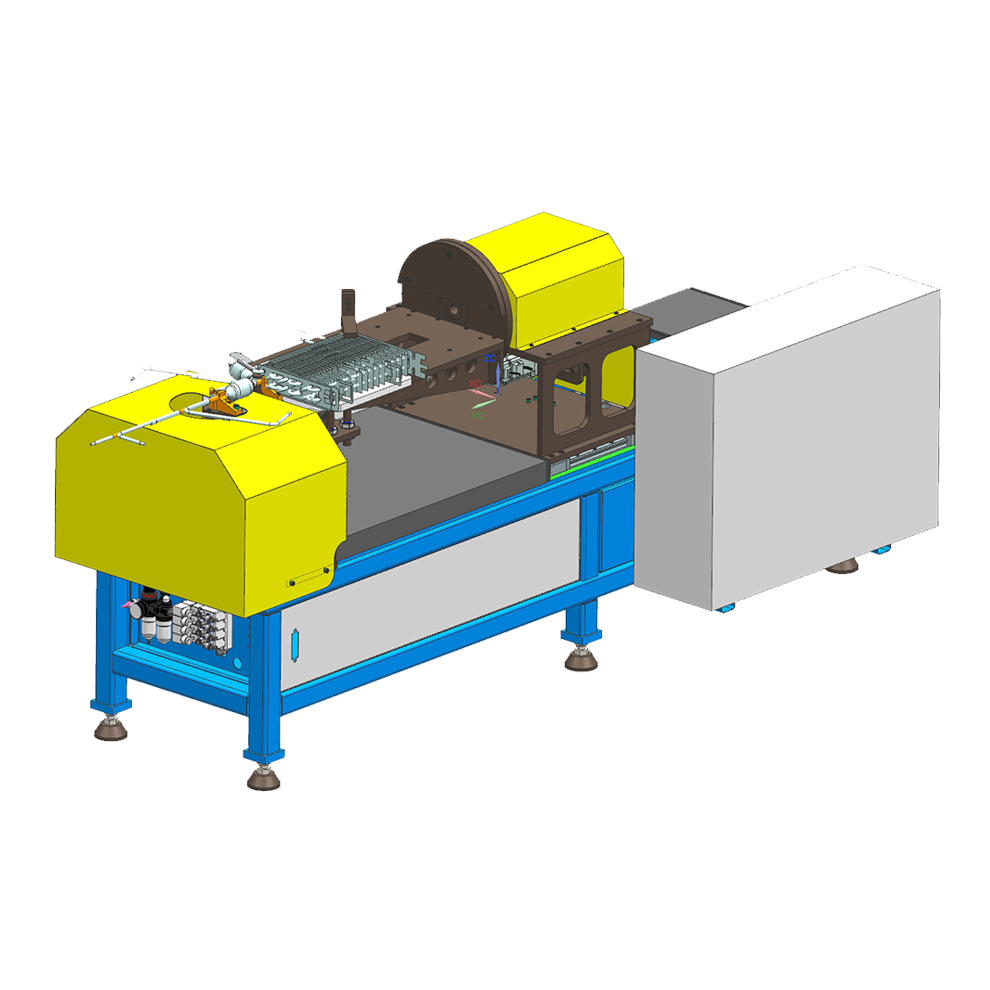

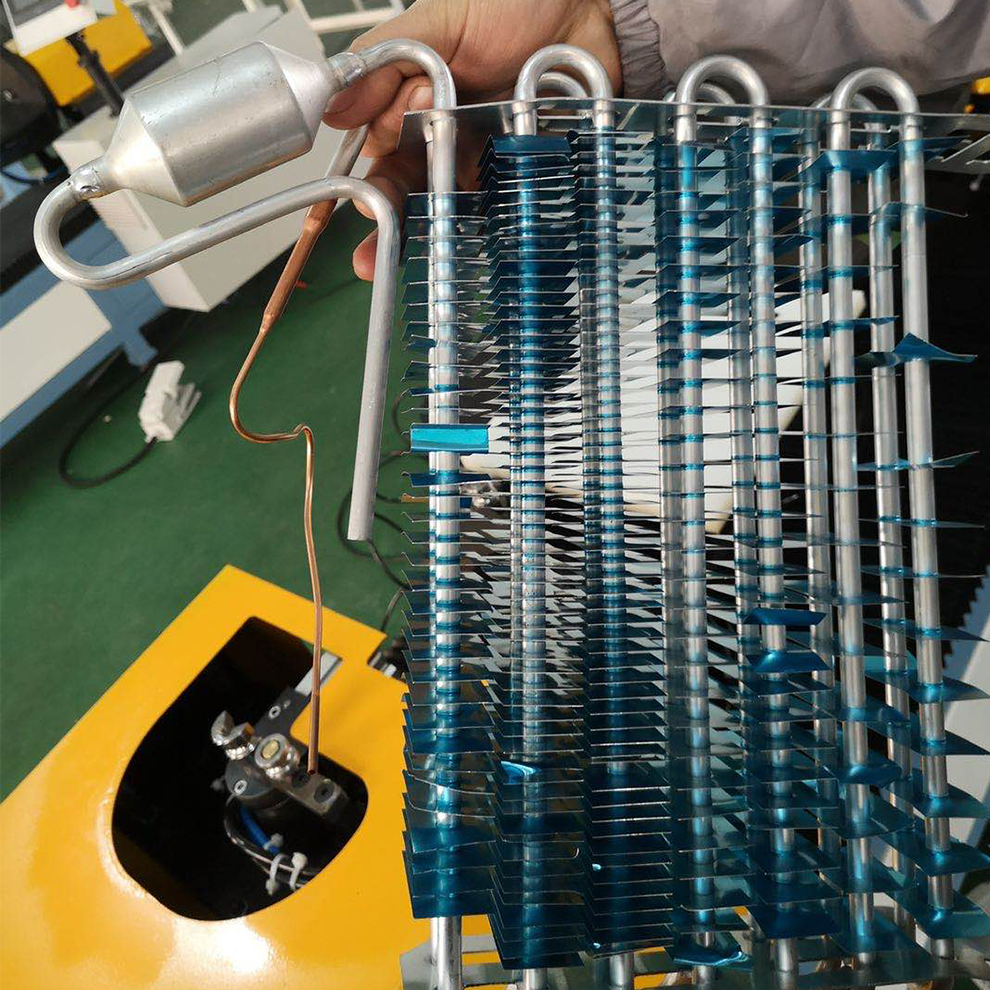

The Wire On Tube Condenser Welding Machine (Model: MF-160-6) is a high-performance equipment designed for efficient and precise welding of wires onto tube condensers. With a rated capacity of 160KVA and a duty cycle of 50%, this machine is capable of handling demanding welding applications in industrial settings.

Parameter

Model | MF-160-6 | |

|---|---|---|

| Input Power | Three-phase four-wire 380V±10% 50HZ | |

| Rated Capacity | 160KVA | |

| Rated Duty-cycle | 50% | |

| Adjustable Steps of Secondary Voltage | 2 Steps | |

| Maximum Secondary Short-circuit Current | 40KA | |

| Transformer Insulation Grade | Grade F | |

| Network Voltage Floating Compensation | When the rated value of network voltage fluctuates within±10%, | |

| The secondary voltage will be ≤±3% | ||

Model | MF-160-6 | |

|---|---|---|

| Welder Pressurized Curves | 3 types | |

| Storage of Welding Models | 101 types | |

| Effective Welding Length | 1270mm | |

| Effective Welding Width | 600mm | |

| Upper Electrode Stroke | 80mm | |

| Lower Electrode Adjustable Stroke | 30mm | |

| Size of Row Welding | 20x100mm | |

Features

Adaptive Power & Stability Control

Intelligent Welding Parameter Management

Oversized Workspace with Precision Tooling

Industrial-Grade Durability

Application

FAQ

Yes, the cooperation support will not end after waranty period. But the price of component for replacement should be at cost price, while in waranty period this price is free. In addition, if you offer a new order of equipment, the price could be communicated.

All 11 Types of Delivery Terms Accepted: EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP.

Yes, we could provide private label or white label services. Customization services are available according to your demands.

Yes. We provide on-site set up services. install, commissioning, calibration and debugging services are offered by our engineers. You can send us your lead time demands and we offer you ideal solusions.

Other than tube processing machines, we also provide fin and finned tube processing machines,including fin making machines andfinned tube processing machines.